Introduction to High-Performance Float Glass Solutions

In the demanding landscape of modern architecture, automotive, and specialized industrial applications, the foundational material for transparent and translucent structures is often high-quality glass. Among the various glass types, clear float glass stands as a cornerstone, renowned for its exceptional optical clarity, superior flatness, and consistent thickness. This material is produced by a meticulous process that results in a sheet of glass with parallel surfaces, providing undistorted vision and making it ideal for a vast array of B2B applications where precision and aesthetic appeal are paramount. From towering building facades to sophisticated solar panels, its versatility is unmatched, setting the benchmark for performance and reliability in diverse industry sectors.

The Manufacturing Process: Precision in Float Glass Production

The production of clear float glass is a testament to advanced industrial engineering, employing the Pilkington float process, which has revolutionized glass manufacturing. This method ensures a consistently high-quality product, distinguishing it from traditional rolled or drawn glass.

Process Flow:

-

Batch Mixing: High-purity silica sand, soda ash, dolomite, limestone, and cullet (recycled glass) are precisely weighed and mixed. The quality of these raw materials directly impacts the optical and mechanical properties of the final clear float glass.

-

Melting: The batch materials are fed into a furnace and heated to approximately 1600°C. This high-temperature melting process ensures a homogeneous molten glass, free from impurities and air bubbles. Energy efficiency and precise temperature control are critical at this stage.

-

Floating on Molten Tin: The molten glass flows from the furnace onto a bath of molten tin. Being lighter than glass, the tin creates a perfectly flat surface, allowing the glass to spread uniformly. Surface tension dictates the inherent smoothness and parallelism of the glass surfaces, eliminating the need for grinding or polishing.

-

žarenje: As the glass ribbon moves along the tin bath, it cools gradually in a controlled environment known as an annealer (lehr). This annealing process relieves internal stresses that could lead to cracking, enhancing the mechanical strength and durability of the glass. The cooling rate is meticulously managed to ensure optimal stress distribution.

-

Cutting and Inspection: Once cooled, the continuous ribbon of glass is automatically cut into desired sizes. Rigorous optical and dimensional inspection, often employing automated laser systems, ensures that each sheet of clear float glass meets stringent quality standards, including ISO 9001 for quality management and ANSI Z97.1 for safety glazing materials.

The service life of clear float glass is exceptionally long, often exceeding 50 years when properly installed and maintained. Its inherent properties make it suitable for target industries such as architectural building (curtain walls, windows), automotive (windshields, side windows), solar energy (photovoltaic panels, thermal collectors), and specialized electronics. Advantages in typical application scenarios include significant energy saving through optimized thermal performance, superior corrosion resistance in diverse environments, and excellent light transmission for maximal daylighting.

Figure 1: Overview of the Float Glass Manufacturing Process.

Technical Specifications and Parameters

Understanding the precise technical parameters is crucial for specifying the correct clear float glass for any project. The performance of the glass is dictated by its thickness, light transmittance, U-value, and other optical and mechanical properties.

Standard Product Specifications (Indicative):

| Parameter |

2mm Thickness |

4mm Thickness (e.g., 4mm clear float glass) |

6mm Thickness |

10mm Thickness (e.g., 10 mm plain glass price, 10mm clear glass price) |

12mm Thickness (e.g., 12mm clear glass price) |

19mm Thickness |

| Visible Light Transmittance (%) |

~91% |

~90% |

~89% |

~87% |

~85% |

~80% |

| Solar Heat Gain Coefficient (SHGC) |

~0.92 |

~0.89 |

~0.86 |

~0.82 |

~0.78 |

~0.69 |

| U-Value (W/m²K, single pane) |

~6.0 |

~5.8 |

~5.7 |

~5.5 |

~5.4 |

~5.2 |

| Density (kg/m³) |

~2500 kg/m³ (Consistent across thicknesses) |

| Modulus of Elasticity (GPa) |

~70 GPa |

| Softening Point (°C) |

~700-730°C |

These parameters are critical for structural engineers, architects, and product designers. For instance, the U-value dictates thermal performance, directly impacting energy consumption in buildings. High visible light transmittance is essential for natural illumination, while the SHGC influences solar heat gain, which can be critical for climate control strategies.

Industry Trends and Market Dynamics

The global market for clear float glass is experiencing robust growth, driven by several key trends. Urbanization, particularly in emerging economies, fuels demand for new construction, while increasing awareness of energy efficiency and sustainability prompts the adoption of advanced glazing solutions.

-

Sustainability & Green Building: There's a growing emphasis on environmentally friendly building materials. Manufacturers are innovating to reduce the carbon footprint of glass production and developing products that contribute to LEED and BREEAM certifications through improved insulation and solar control properties.

-

Smart Glass Integration: The integration of clear float glass with smart technologies, such as electrochromic or thermochromic coatings, allows for dynamic control over light, glare, and heat, enhancing user comfort and energy efficiency. This trend is particularly evident in high-end commercial and residential projects.

-

Increased Demand for Larger Panels: Architectural designs are trending towards larger, uninterrupted glass panels to maximize views and natural light. This necessitates stronger, more dimensionally stable float glass and advanced handling techniques.

-

Enhanced Security Features: With rising security concerns, there's an increased demand for laminated or tempered clear float glass, offering superior resistance to impact, forced entry, and blast protection.

-

Cost-Effectiveness and Price Stability: While raw material costs fluctuate, the mature production process of clear float glass ensures relative price stability, making it an economically viable choice for large-scale projects, including competitive pricing for `10 mm plain glass price` or `12mm clear glass price` points.

Application Scenarios and Target Industries

The inherent properties of clear float glass make it indispensable across a spectrum of industries, providing solutions that combine aesthetics with high performance.

-

Architectural & Construction: As primary glazing for windows, doors, facades, curtain walls, skylights, and interior partitions. Its clarity maximizes natural light, reducing reliance on artificial lighting and contributing to energy saving. For example, double-glazed units using 4mm clear float glass can significantly improve insulation.

-

Automotive Industry: Used in windshields, side windows, and backlights, where optical clarity and robust mechanical strength are crucial for safety and driver visibility. The float process ensures minimal distortion.

-

Solar Energy Sector: As a cover plate for solar thermal collectors and photovoltaic modules. Its high light transmission and durability against environmental factors are key. Specialized low-iron float glass variants further enhance efficiency.

-

Furniture & Interior Design: For table tops, shelves, display cases, and mirrors due to its smooth surface and aesthetic appeal.

-

Electronics & Appliances: In refrigerator doors, oven doors, and display screens where heat resistance, flatness, and visual quality are important.

-

Water Supply & Drainage / Petrochemical / Metallurgy: While not used directly in fluid containment, it serves in control room glazing, observation panels for non-pressurized environments, and as a base for specialized coatings that offer corrosion resistance in demanding industrial settings. Its fundamental properties provide a reliable base for subsequent processing (e.g., tempering, laminating) to meet the severe requirements of these sectors.

Figure 2: Architectural applications highlighting the aesthetic and functional benefits.

Technical Advantages of Clear Float Glass

The widespread adoption of clear float glass is largely attributed to its compelling technical advantages:

-

Exceptional Optical Clarity: Provides superior light transmission and minimizes visual distortion, offering true-color vision. This is critical for applications requiring high aesthetic standards and clear views.

-

Consistent Thickness and Flatness: The float process naturally produces glass with uniform thickness and extremely flat, parallel surfaces, crucial for precision applications and ensuring ease of fabrication into insulated glazing units (IGUs) or laminated glass.

-

Versatility for Further Processing: Acts as an ideal substrate for a wide range of secondary processes including tempering, laminating, coating, etching, sandblasting, and silvering (for mirrors). This allows for customization to meet specific performance requirements like safety, security, solar control, and aesthetics.

-

Durability and Longevity: Inherently resistant to environmental degradation, UV radiation, and most chemical agents, ensuring a long operational life with minimal maintenance.

-

Cost-Effectiveness: Given its advanced manufacturing process and high-volume production capabilities, clear float glass offers excellent value, especially when considering its performance benefits and longevity.

Vendor Comparison and Selection Criteria

Selecting the right supplier for clear float glass is critical for project success, impacting quality, lead times, and overall cost-effectiveness. A thorough evaluation should consider several key factors.

Key Comparison Factors:

| Criterion |

Leading Supplier (e.g., Shanghai ZR Glass) |

Competitor A (General Market) |

Competitor B (Value-Focused) |

| Product Quality & Consistency |

Excellent (ISO 9001, CE Certified, rigorous QC) |

Good (Standard compliance, occasional variability) |

Acceptable (Meets minimum standards) |

| Certifications & Standards |

ISO, CE, ANSI, SGCC |

ISO, CE (Basic) |

Local Standards |

| Customization Capabilities |

High (Specific dimensions, processing, coatings) |

Moderate (Standard dimensions, limited processing) |

Low (Off-the-shelf only) |

| Lead Time & Logistics |

Efficient (Global logistics network, consistent delivery) |

Average (Can vary with order size) |

Longer (Less optimized supply chain) |

| Technical Support & Expertise |

Dedicated specialists, project consultation |

Basic support |

Limited to product specifications |

| After-Sales Service |

Comprehensive warranty, responsive issue resolution |

Standard warranty, slower response |

Minimal or short-term warranty |

Beyond these, consider a vendor's years of experience in the industry, their track record with major clients, and their commitment to research and development. A reputable supplier will not only provide competitive `10mm clear glass price` options but also ensure reliability throughout the project lifecycle.

Customized Solutions and Design Flexibility

While standard sizes and thicknesses of clear float glass are widely available, many B2B projects require bespoke solutions. Customization capabilities are a hallmark of a proficient glass supplier, allowing architects and designers to realize unique visions without compromising performance.

-

Tailored Dimensions: Glass can be cut to precise lengths and widths, including oversized panels for expansive facades or specific industrial machinery requirements.

-

Varied Thicknesses: Beyond the standard 2mm to 19mm, specialized thicknesses of clear float glass can be supplied to meet unique structural or acoustic demands.

-

Edge Work and Finishing: Options include polished edges, beveled edges, drilled holes, notches, and other custom fabrications essential for installation and aesthetic integration.

-

Surface Treatments and Coatings:

- Low-E (Low Emissivity) Coatings: Significantly improve thermal insulation, reducing heat transfer and enhancing energy saving.

- Solar Control Coatings: Reflect or absorb solar radiation, minimizing heat gain and glare.

- Self-Cleaning Coatings: Utilize photocatalytic action to break down organic dirt, reducing maintenance.

- Anti-Reflective Coatings: Enhance light transmission for applications like display cases or solar panels.

-

Processing into Advanced Glass Products:

- Tempering: Increases strength by up to five times, making the glass safer by shattering into small, blunt pieces if broken.

- Laminating: Bonds multiple layers of glass with an interlayer (e.g., PVB, SGP) for enhanced security, sound insulation, and UV protection.

- Insulated Glass Units (IGUs): Two or more panes of glass sealed with a gas-filled space for superior thermal and acoustic performance.

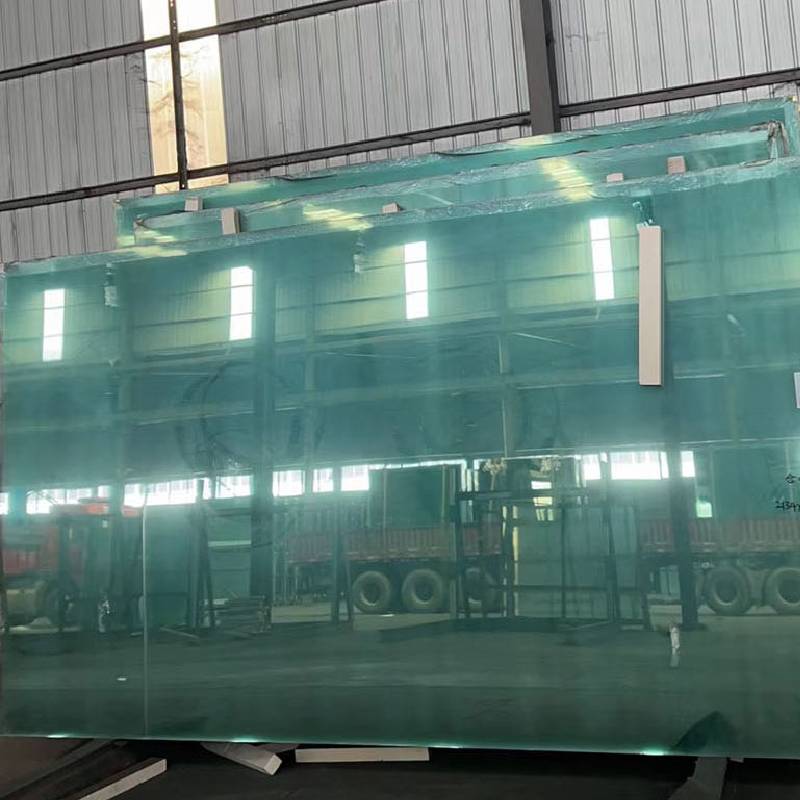

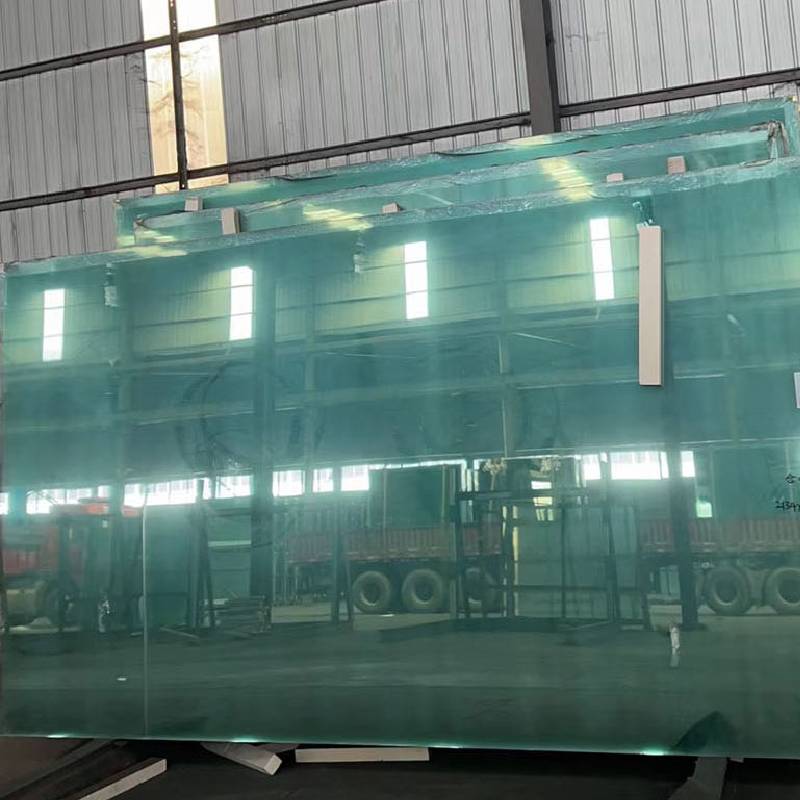

Figure 3: Customized float glass being prepared for specialized architectural installation.

Real-World Application Case Studies

Our extensive experience in providing clear float glass solutions to diverse sectors is underscored by successful project implementations, demonstrating our commitment to quality and client satisfaction.

Case Study 1: Commercial High-Rise Facade

-

Client: Major urban development corporation.

-

Challenge: To supply large format, high-performance glass panels for a new commercial skyscraper, requiring exceptional clarity, thermal efficiency, and wind load resistance.

-

Solution: We provided custom-sized, 12mm clear float glass, processed into insulated glass units with a low-emissivity coating. This met strict energy performance targets and provided superior acoustic insulation for a bustling city environment.

-

Outcome: The project achieved its LEED certification goals, with the glass contributing significantly to reduced HVAC costs and enhanced occupant comfort. The client praised the consistent quality and on-time delivery.

Case Study 2: Solar Farm PV Module Covers

-

Client: Leading renewable energy developer.

-

Challenge: To supply robust, highly transparent glass for over 100,000 photovoltaic modules, capable of withstanding harsh environmental conditions while maximizing solar energy capture.

-

Solution: We supplied specialized low-iron 4mm clear float glass, which offered exceptional solar transmittance and high resistance to abrasion and impact. The glass underwent a tempering process to enhance its mechanical strength against hail and wind.

-

Outcome: The solar farm achieved optimal energy output, benefiting from the glass's high efficiency and long-term durability. Our ability to scale production and manage complex logistics was key to the project's timely completion.

Figure 4: A completed architectural project demonstrating the integration of advanced glass solutions.

Ensuring Trust and Reliability ( Focus)

At Shanghai ZR Glass, we prioritize expertise, experience, authoritativeness, and trustworthiness () in every aspect of our operations, ensuring our clients receive not just products, but comprehensive, reliable solutions.

Company Certifications & Partnerships:

-

ISO 9001:2015 Certified: Demonstrates our commitment to a robust quality management system across all manufacturing and operational processes.

-

CE Mark Compliance: Our products meet the essential health and safety requirements of European directives, allowing for free movement within the European Economic Area.

-

ANSI Z97.1 & SGCC Certified: Assurance of safety glazing materials that meet stringent industry standards for impact resistance.

-

Strategic Partnerships: Collaborations with leading architectural firms, construction companies, and material suppliers, underscoring our integral role in the supply chain for high-profile projects.

Quality Assurance & Testing Standards:

Every batch of clear float glass undergoes rigorous testing to ensure compliance with international and client-specific standards. This includes optical clarity tests, dimensional checks, stress analysis, and mechanical strength assessments. We adhere strictly to standards such as ASTM C1036 (Standard Specification for Flat Glass) and EN 572 (Glass in Building – Basic soda-lime silicate glass products).

Warranty and After-Sales Support:

We stand behind the quality of our products with comprehensive warranty commitments, typically ranging from 5 to 10 years, depending on the product type and application. Our dedicated after-sales support team provides technical assistance, guidance on maintenance, and prompt resolution of any issues, ensuring long-term product satisfaction.

Lead Time and Fulfillment:

Our streamlined production process and efficient global logistics network enable competitive lead times. Standard orders for clear float glass typically ship within 15-20 business days, while customized or large-volume orders are managed with clear communication and project timelines, often taking 30-45 business days. We provide real-time updates on order status and collaborate closely with clients for just-in-time delivery where required.

Frequently Asked Questions (FAQ)

Q1: What is the primary difference between clear float glass and ordinary sheet glass?

A1: Prozirno float staklo is manufactured by floating molten glass on a bed of molten tin, resulting in a glass with extremely flat, parallel surfaces and uniform thickness, offering superior optical clarity and minimal distortion. Ordinary sheet glass (drawn glass) is typically less flat, with some surface imperfections, leading to more optical distortion.

Q2: Can clear float glass be used in high-impact areas?

A2: Standard clear float glass is not recommended for high-impact areas. However, it can be further processed into tempered (toughened) glass or laminated glass, which are specifically designed for safety and high-impact resistance, suitable for applications like storefronts, balustrades, or automotive glass.

Q3: What are the typical thicknesses available for clear float glass, and how do they impact pricing?

A3: Common thicknesses range from 2mm to 19mm, with 4mm, 6mm, 8mm, 10mm, and 12mm being most prevalent. Thicker glass generally commands a higher price (e.g., `12mm clear glass price` will be higher than `4mm clear float glass` price) due to increased material usage and longer processing times, but also offers greater structural integrity and acoustic performance.

Q4: Is clear float glass energy efficient?

A4: While single-pane clear float glass offers limited thermal insulation, its properties make it an excellent base for creating energy-efficient products. When fabricated into Insulated Glass Units (IGUs) with low-emissivity (Low-E) coatings or argon gas fills, it significantly enhances thermal performance, reducing energy consumption for heating and cooling.

Conclusion

Prozirno float staklo remains an indispensable material in the global B2B landscape, pivotal for its optical clarity, uniformity, and versatility. As industries evolve towards greater sustainability and performance, the continuous advancements in float glass manufacturing and secondary processing ensure its relevance and superior positioning. Partnering with a trusted manufacturer like Shanghai ZR Glass, known for its commitment to quality, technical expertise, and customer-centric solutions, ensures that your projects benefit from the highest standards of this fundamental material. From initial specification to final installation, our aim is to provide unparalleled support and products that consistently exceed expectations.

References

- Pilkington, Alastair. "The Pilkington float glass process." Proceedings of the Royal Society of London. Series A. Mathematical and Physical Sciences 314.1517 (1969): 1-25.

- International Organization for Standardization. ISO 9001:2015 Quality management systems – Requirements.

- American Society for Testing and Materials. ASTM C1036-16 Standard Specification for Flat Glass.

- European Committee for Standardization. EN 572-1:2012 Glass in building – Basic soda-lime silicate glass products – Part 1: Definitions and general physical and mechanical properties.

- National Fenestration Rating Council (NFRC). NFRC 100: Procedure for Determining Fenestration Product U-Factors.

afrički

afrički  albanski

albanski  amharski

amharski  arapski

arapski  Armenac

Armenac  azerbajdžanski

azerbajdžanski  baskijski

baskijski  bjeloruski

bjeloruski  bengalski

bengalski  bosanski

bosanski  bugarski

bugarski  katalonski

katalonski  Cebuano

Cebuano  Korzikanac

Korzikanac  Hrvatski

Hrvatski  češki

češki  danski

danski  nizozemski

nizozemski  Engleski

Engleski  esperanto

esperanto  estonski

estonski  finski

finski  francuski

francuski  frizijski

frizijski  galicijski

galicijski  gruzijski

gruzijski  njemački

njemački  grčki

grčki  gudžarati

gudžarati  haićanski kreolski

haićanski kreolski  kuća

kuća  havajski

havajski  hebrejski

hebrejski  Ne

Ne  Miao

Miao  mađarski

mađarski  islandski

islandski  igbo

igbo  indonezijski

indonezijski  irski

irski  talijanski

talijanski  japanski

japanski  javanski

javanski  kannada

kannada  kazahstanski

kazahstanski  kmerski

kmerski  ruandski

ruandski  korejski

korejski  kurdski

kurdski  Kirgistan

Kirgistan  TBC

TBC  latinski

latinski  latvijski

latvijski  litvanski

litvanski  luksemburški

luksemburški  makedonski

makedonski  Malgaši

Malgaši  malajski

malajski  malajalamski

malajalamski  malteški

malteški  maorski

maorski  marati

marati  mongolski

mongolski  Mianmar

Mianmar  nepalski

nepalski  norveški

norveški  norveški

norveški  oksitanski

oksitanski  paštunski

paštunski  perzijski

perzijski  Polirati

Polirati  Portugalski

Portugalski  pandžapski

pandžapski  rumunjski

rumunjski  ruski

ruski  Samoanac

Samoanac  škotski galski

škotski galski  srpski

srpski  Engleski

Engleski  Shona

Shona  sindhi

sindhi  sinhalski

sinhalski  slovački

slovački  slovenski

slovenski  somalijski

somalijski  španjolski

španjolski  sundanski

sundanski  svahili

svahili  švedski

švedski  tagalog

tagalog  tadžički

tadžički  Tamil

Tamil  tatarski

tatarski  teluški

teluški  tajlandski

tajlandski  turski

turski  turkmenski

turkmenski  ukrajinski

ukrajinski  urdu

urdu  ujgurski

ujgurski  uzbečki

uzbečki  vijetnamski

vijetnamski  velški

velški  Pomozite

Pomozite  jidiš

jidiš  joruba

joruba  zulu

zulu