The Process of Tempered Glass A Comprehensive Overview

Tempered glass, also known as toughened glass, is a type of safety glass that has been treated to enhance its strength and durability. The process of making tempered glass involves several key steps that transform ordinary glass into a product that can withstand high levels of stress and temperature variations. This article explores the intricate process of manufacturing tempered glass, its benefits, and applications.

1. Raw Material Selection

The process begins with selecting the right type of raw glass. Typically, soda-lime glass is used, which consists of silica, soda, and lime. This basic composition is crucial as it will undergo various treatments to improve its properties. The glass sheets are carefully inspected for any imperfections before proceeding to the next stage.

2. Cutting and Shaping

Once the raw glass is selected, it is cut into the desired shapes and sizes. This is done using specialized cutting tools that ensure precision. The edges of the cut glass are smoothed and polished to remove sharp edges, making it safer for handling and installation. It is essential to note that once the glass is cut, any subsequent alterations, such as drilling holes or edges, are typically not performed because this can compromise the tempered integrity.

3. Annealing

After cutting, the glass undergoes an annealing process. This involves slowly cooling the glass from its fabrication temperature to relieve internal stresses that occur during the cutting process. The annealing helps ensure that the glass maintains uniform thickness and reduces the risk of breakage later in the process.

4. Tempering

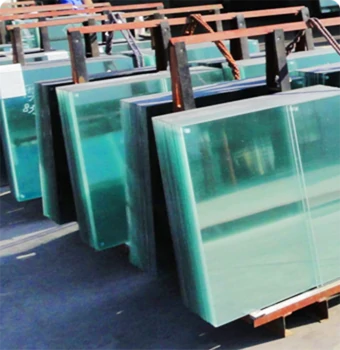

process of tempered glass

The core of the tempered glass manufacturing process is the tempering stage, which is where the glass becomes toughened. The glass sheets are then subjected to extreme heating, usually to temperatures of around 600 to 800 degrees Celsius (1,112 to 1,472 degrees Fahrenheit) in a tempering furnace. This step helps to create a uniform thermal profile throughout the glass.

Once the glass reaches the target temperature, it is rapidly cooled—this is known as quenching. The rapid cooling creates a compression layer on the surface of the glass, while the interior remains under tension. This unique combination of compressive and tensile stresses greatly enhances the strength of the glass, making it approximately four to five times stronger than untreated glass of the same thickness.

5. Quality Control

After the tempering process, the glass pieces undergo rigorous quality control inspections to ensure they meet safety and performance standards. This involves checking for any defects, such as bubbles, distortions, or discrepancies in thickness. These inspections are crucial as any flaws can compromise the integrity and safety of the tempered glass.

6. Applications of Tempered Glass

Tempered glass is widely used in various applications due to its enhanced strength and safety features. It is commonly found in the automotive industry, particularly in side and rear windows, where strength and shatter resistance are vital. In the architectural field, tempered glass is used for facades, shower doors, and glass railings, providing both safety and aesthetic appeal.

Additionally, it is used in kitchen countertops, appliances, and glass doors due to its resistance to heat and thermal shock. The versatility of tempered glass has made it a preferred material across different industries, including furniture design, commercial buildings, and interior decor.

Conclusion

The process of manufacturing tempered glass is an intricate blend of science and technology. From the careful selection of raw materials to the extreme conditions of the tempering process, each step is crucial in creating a final product that is strong, safe, and suited to various applications. As the demand for safety and durability in construction and design continues to grow, the importance of tempered glass remains significant in our modern world.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu