The advent of toughened glass marked a significant leap in safety and durability for modern products, making its way into everything from car windows to smartphone screens and architectural structures. However, understanding how and why toughened glass breaks not only enhances consumer knowledge but also boosts product development and safety management, offering practical insights based on both experience and expertise.

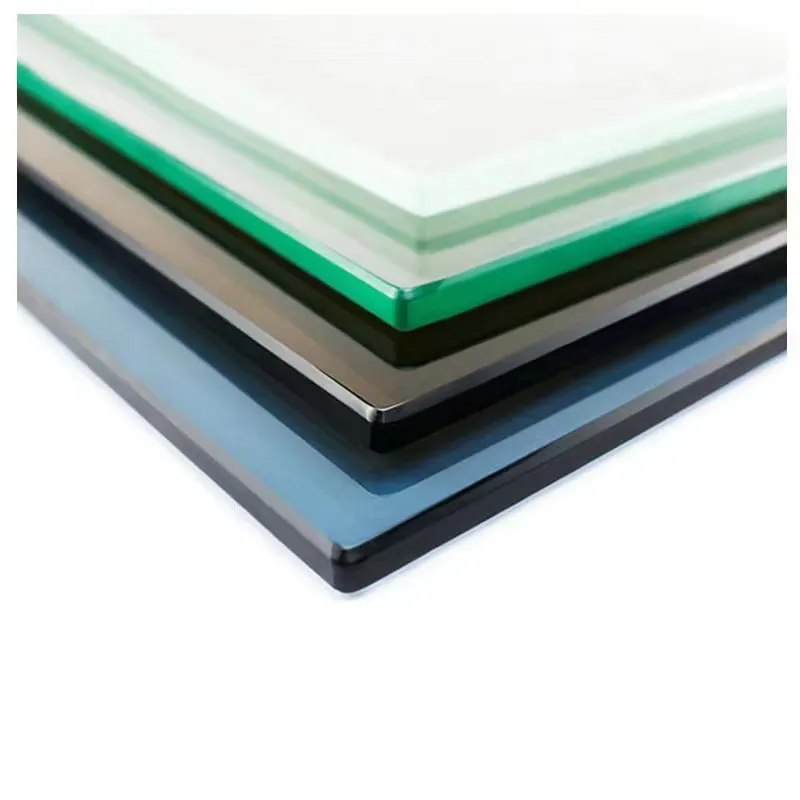

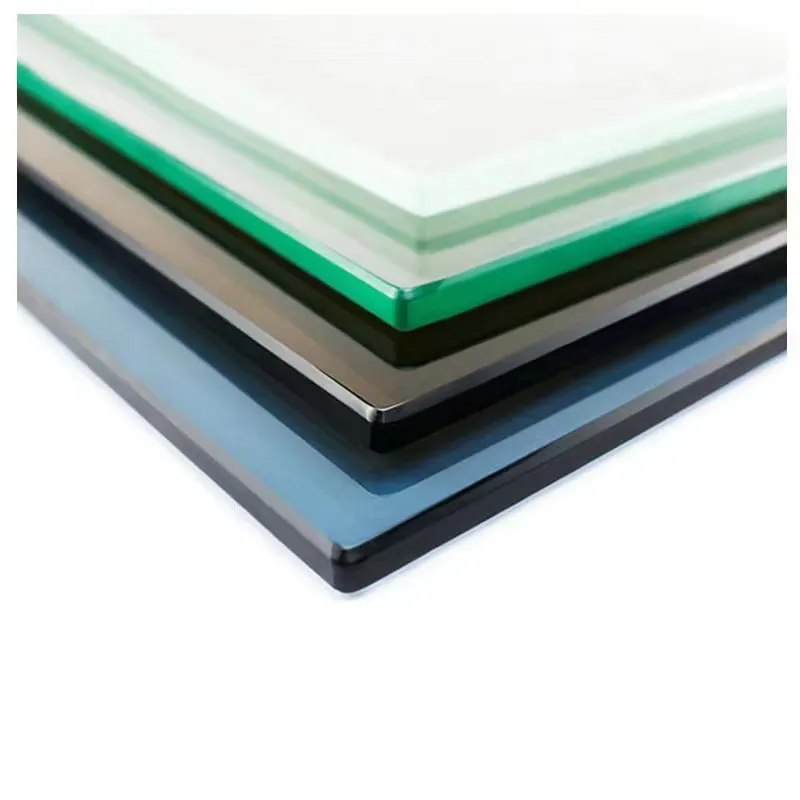

Toughened glass, also known as tempered glass, undergoes a specialized heat-treatment process that strengthens it considerably compared to regular glass. This process involves heating the glass to a high temperature and then rapidly cooling it, a technique known as quenching. Through this process, the exterior of the glass cools faster than the interior, putting the surface in compression and the interior in tension, thus increasing its strength and making it up to five times harder than untreated glass.

From an experiential standpoint, products crafted from toughened glass often impress with their resilience in everyday scenarios—accommodating impacts that regular glass cannot withstand without shattering. This remarkable toughness is why it’s commonly employed in environments where safety and reliability are paramount. However, its impressive strength does not make it impervious to damage. Understanding the conditions under which toughened glass may break is crucial for businesses and consumers alike who rely on its integrity and performance.

One of the key insights about toughened glass breaking is the nature of its fracture pattern. Unlike ordinary glass that shatters into sharp shards,

toughened glass is designed to break into blunt, small-granule pieces. This characteristic reduces the risk of injury upon breakage, which is especially vital in automotive and architectural applications. This breakage pattern emanates from the inherent stresses evenly distributed across the glass surface and is an asset in enhancing safety, reaffirming its trustworthiness as a product material.

toughened glass breaking

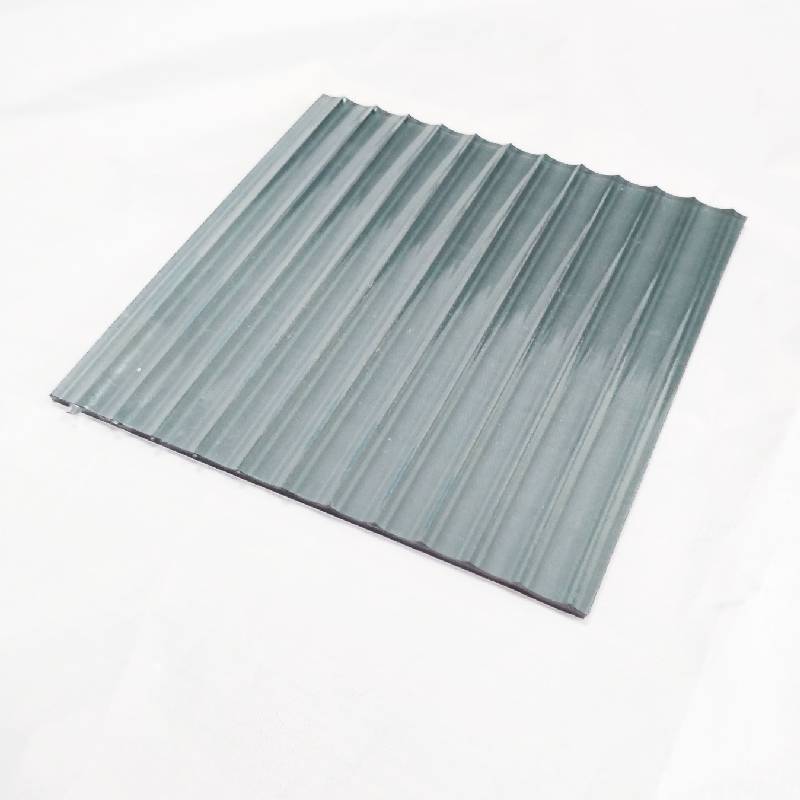

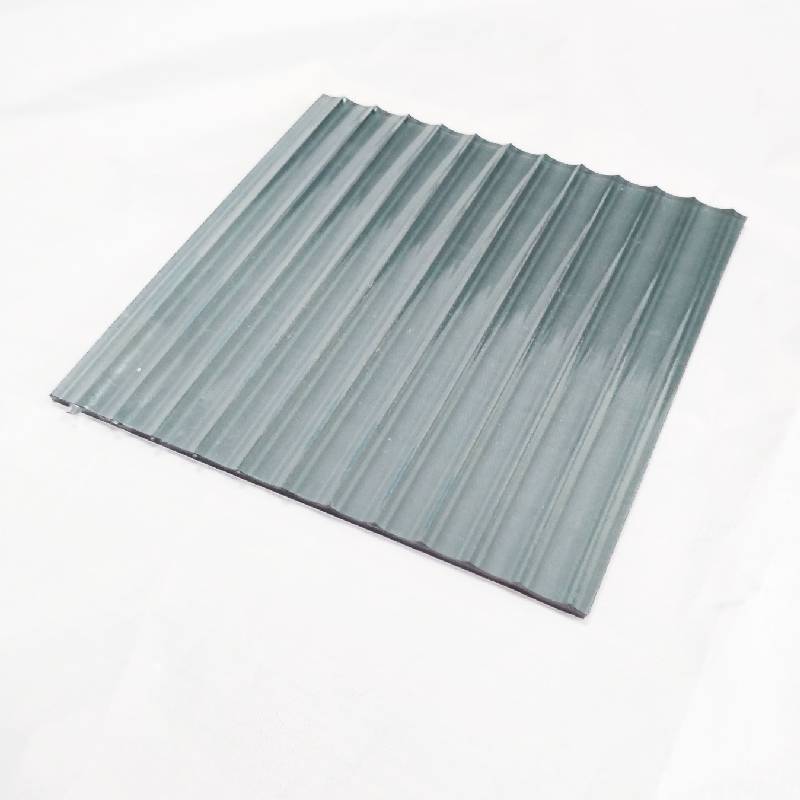

Despite its engineered durability, toughened glass can indeed break, primarily due to extreme localized pressure or substantial surface damage. Professionally, it is recognized that flaws introduced during handling or installation—such as scratches or chips—can act as focal points for stress concentration, potentially leading to spontaneous breakage. For instance, in architectural applications, improperly installed glass panes with edge damage are more susceptible to breaking upon thermal expansion or impact.

Moreover, a phenomenon known as 'spontaneous glass breakage' can occur, albeit rarely, due to inclusions within the glass material itself, such as nickel sulfide. These inclusions, emerging from the manufacturing process, may change composition over time, leading to a delayed transformation that can result in the glass pane breaking unexpectedly. Such occurrences, although infrequent, underscore the importance of meticulous quality control and monitoring during both manufacturing and installation phases for those in product development and engineering fields.

In the sphere of expertise, the critical evaluation of toughened glass in both controlled and real-world environments continually enhances the design processes, material selection, and safety protocols utilized by engineers and manufacturers. Innovators in glass technology advocate for the regular assessment and updating of safety standards to incorporate advancements and research findings, solidifying the authoritative standards that guide robust product creation and application.

Overall, toughened glass stands as a testament to human ingenuity in material science, embodying a compelling balance between strength and safety. For consumers, industry experts, and manufacturers alike, understanding its properties, potential vulnerabilities, and maintenance requirements not only bolsters trust in products employing this material but also drives ongoing improvement and innovation across relevant industries.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu