Tempered Glass Manufacturing Plant A High-Tech Approach to Safety and Durability

Tempered glass, known for its enhanced strength and safety features, is a crucial material in modern architecture, automotive, and various industrial applications. The manufacturing of tempered glass involves a sophisticated process that transforms ordinary glass into a robust product designed to withstand thermal stress and physical impact. This article will delve into the essential stages and technologies employed in a typical tempered glass manufacturing plant.

The journey of manufacturing tempered glass begins with the selection of raw materials. High-quality silica sand, soda ash, and limestone are the primary ingredients, which are meticulously mixed in precise ratios. This mixture is then melted in a furnace at extremely high temperatures, normally around 1,700°F (about 925°C). This process results in molten glass that is refined to eliminate impurities and achieve the desired clarity and consistency. The quality of the initial mixture significantly affects the final product, making this stage pivotal in the manufacturing process.

Once the molten glass is prepared, it is formed into sheets using various methods, such as float glass processing. In the float glass method, molten glass is poured onto a bed of molten tin, creating a flat, smooth surface. After forming, the glass sheets are cooled down gradually to room temperature, a process known as annealing. This stage is crucial for eliminating internal stresses within the glass, ensuring that it maintains integrity during the subsequent tempering process.

The tempering process itself is where the magic happens. The glass sheets undergo a rapid heating and cooling cycle in a tempering furnace. First, the glass is heated to around 1,300°F (about 700°C), which softens it. It is then quickly cooled using powerful jets of air. This rapid cooling process increases the surface tension of the glass, making it substantially stronger than untreated glass. Tempered glass can withstand impacts up to five times greater than regular glass and has a higher resistance to thermal stress.

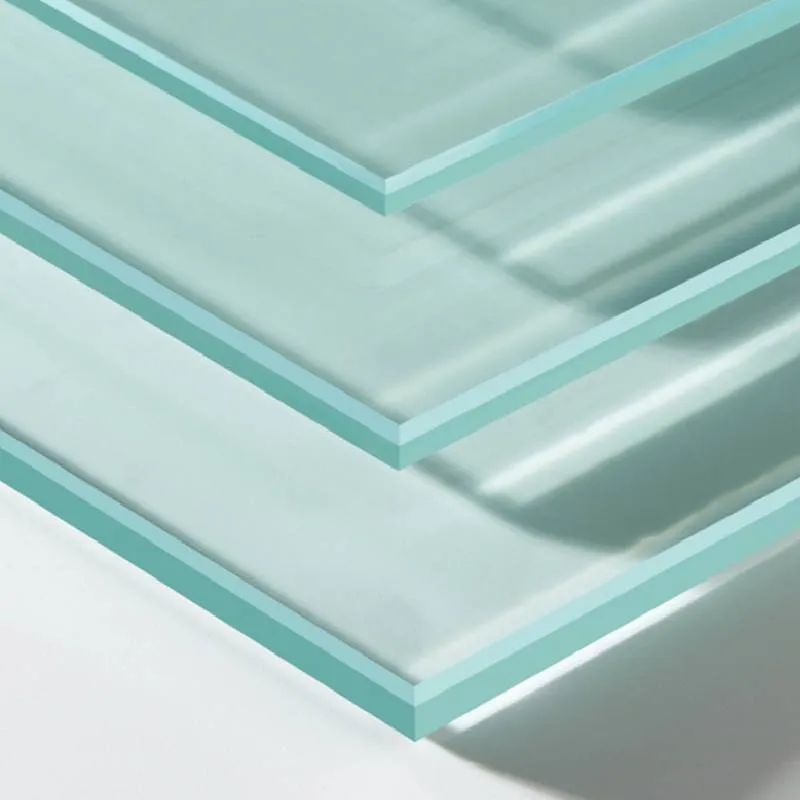

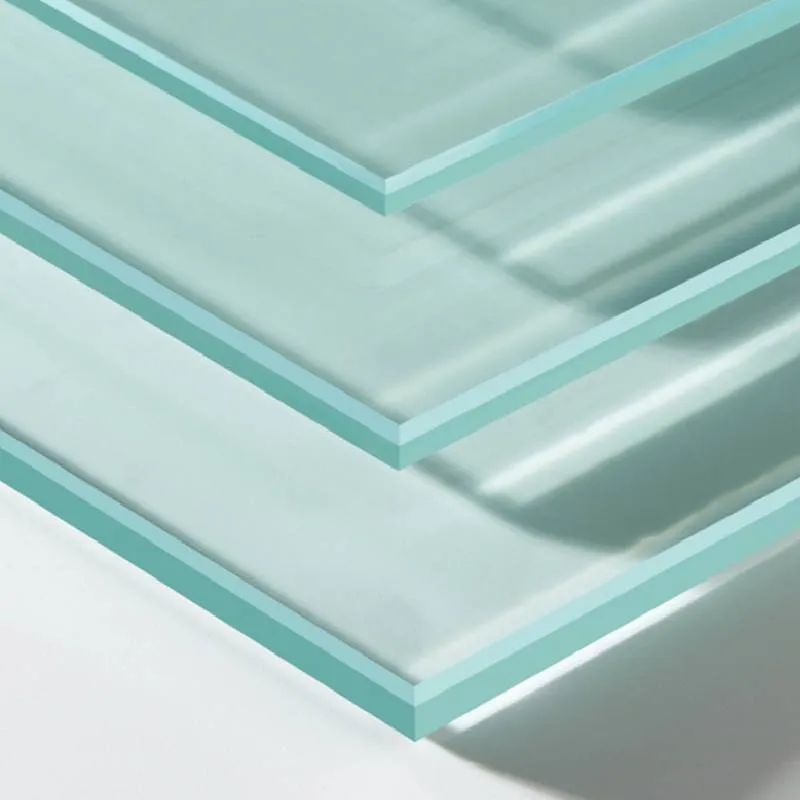

tempered glass manufacturing plant

Safety is a significant concern in the manufacturing environment, as both the materials and the processes involved can present hazards. Therefore, a tempered glass manufacturing plant is equipped with advanced safety systems and technology to protect workers. Personal protective equipment (PPE), safety training, and strict operational protocols are implemented to create a safe working environment.

Quality control is an integral part of the manufacturing process. Every batch of tempered glass undergoes rigorous testing to ensure that it meets industry standards. This includes measurements for thickness, strength tests, and inspections for visual defects. Any glass not meeting the set criteria is discarded or recycled, maintaining high quality and efficiency in production.

In addition to safety and quality, environmental considerations are becoming more critical in tempered glass manufacturing. Many plants are incorporating sustainable practices, such as recycling glass and minimizing energy consumption. Advancements in technology are helping manufacturers reduce waste and improve processing efficiency, aligning with global efforts toward sustainability.

In conclusion, a tempered glass manufacturing plant represents a fusion of art and science, where high-quality materials are transformed into a flexible and durable product. Through meticulous processes and cutting-edge technology, tempered glass plays an essential role in enhancing safety and design in various applications, from towering skyscrapers to stylish vehicles. As industries continue to prioritize strength, safety, and sustainability, tempered glass will undoubtedly remain a vital material for the future.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu