The Evolution and Importance of Toughened Glass Manufacturing Plants

Toughened glass, also known as tempered glass, is a type of safety glass that has been treated to increase its strength and thermal resistance compared to standard glass. The manufacturing process of toughened glass involves heating the glass to high temperatures and then rapidly cooling it, a method that significantly enhances its durability. In recent years, toughened glass manufacturing plants have become increasingly significant due to its diverse applications and the growing demand for advanced building materials.

The demand for toughened glass has surged, primarily driven by its use in architectural applications, automotive industries, and various consumer products. In the architectural sector, toughened glass is favored for its strength and safety features. It is commonly used in facades, roofs, and interior partitions, providing design flexibility while ensuring protection against breakage. In the automotive industry, toughened glass serves a critical role in enhancing passenger safety; windshields and side windows made from toughened glass are designed to withstand impact better than standard glass, reducing the risk of injury in the event of an accident.

The manufacturing process of toughened glass requires a significant investment in specialized equipment and technology. The production begins with the selection of high-quality raw materials, primarily silica sand, soda ash, and limestone. The glass is formed by melting these raw materials in a furnace, followed by shaping using various techniques such as floating or molding. After forming, the glass is slowly cooled down to relieve internal stresses. The next crucial step involves heating the glass in an oven to temperatures ranging from 600 to 700 degrees Celsius, followed by rapid cooling with jets of air. This process, known as tempering, causes the outer surface of the glass to compress while the interior remains in tension, resulting in increased strength.

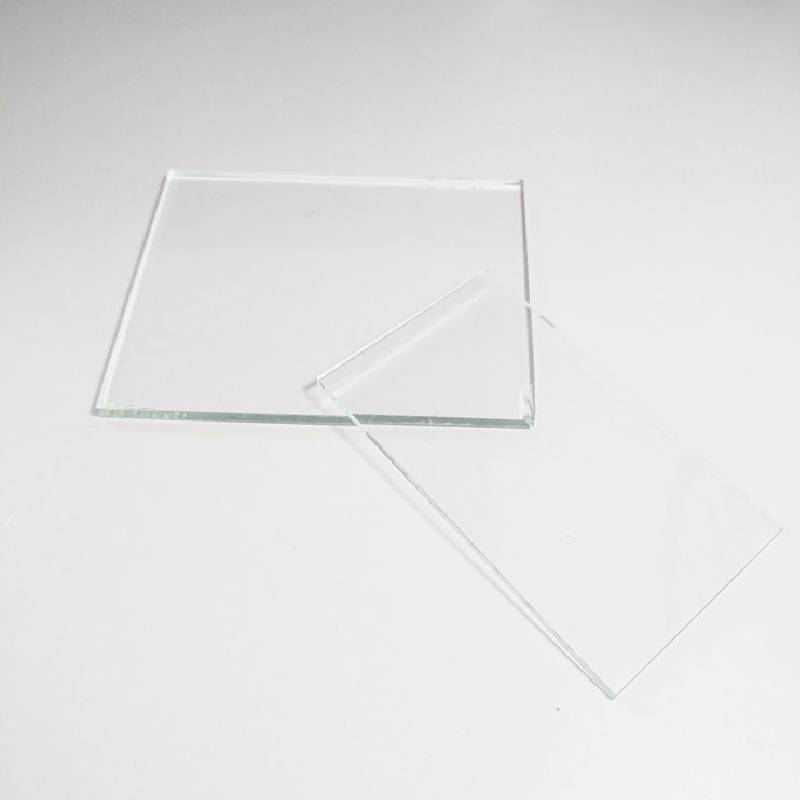

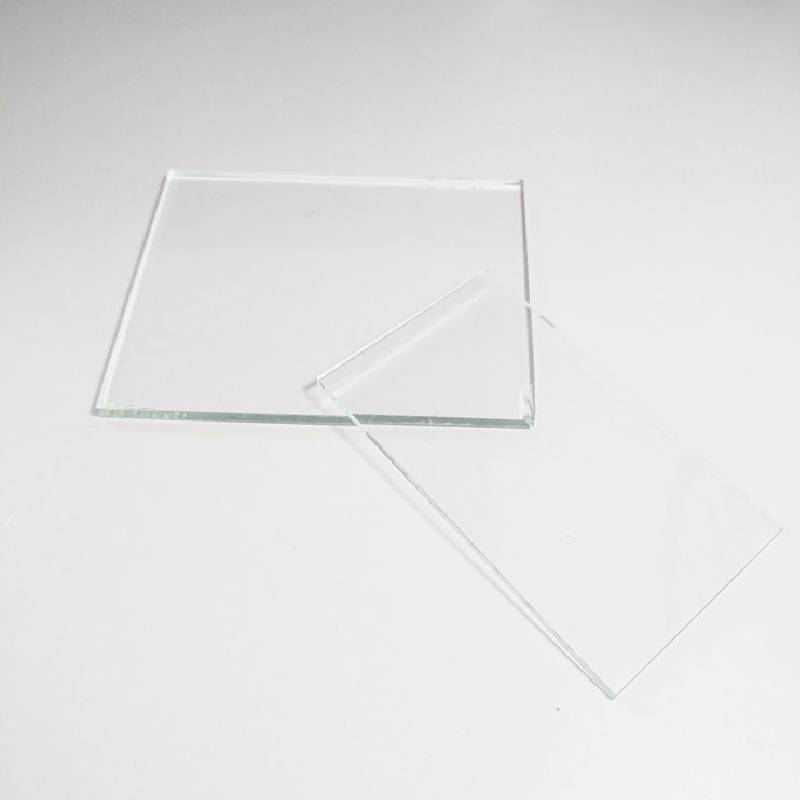

toughened glass manufacturing plant

Safety is a paramount concern in the design and manufacturing of toughened glass products. When broken, toughened glass shatters into small, blunt pieces, reducing the risk of injury compared to traditional glass, which can break into sharp shards. This attribute is particularly vital in environments such as schools, hospitals, and public spaces, where safety is critical. Moreover, toughened glass can withstand higher thermal variations, making it suitable for applications involving heat exposure, such as in kitchens, shower doors, and balcony railings.

To maintain efficiency and competitiveness within the market, modern toughened glass manufacturing plants are increasingly adopting automated and advanced manufacturing technologies

. Automation enhances precision in cutting, shaping, and tempering the glass, leading to fewer defects and waste. Additionally, the use of data analytics and production monitoring systems helps improve operational efficiency by optimizing workflows and reducing energy consumption.

Sustainability is also becoming an integral focus in toughened glass production. Many manufacturers are exploring eco-friendly practices, such as recycling waste materials and using energy-efficient processes. By employing sustainable practices, toughened glass manufacturing plants not only meet regulatory standards but also contribute to a greener environment.

In conclusion, toughened glass manufacturing plants play a vital role in producing one of the most versatile and indispensable materials in modern society. With their applications spanning architecture, automotive, and consumer products, the significance of toughened glass is growing. As technology continues to evolve, these manufacturing plants will likely see advancements in production processes and sustainability practices, further enhancing their contributions to safety and innovation in the industry.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu