Float glass plates have transformed the glass industry with their uniform thickness and impeccable clarity. Widely known as the foundation for various glass products, float glass is produced through a meticulous process that reflects decades of innovation and expertise. As an SEO consultant specializing in product-oriented content, it's crucial to explore these aspects—experience, expertise, authoritativeness, and trustworthiness—when discussing float glass plates.

The manufacture of float glass plates is rooted in a sophisticated technique that has been refined over time. The glass is produced by floating molten glass on a bed of molten tin, forming a sheet with uniform thickness and surface. This process, pivotal in achieving the precision and clarity float glass is renowned for, is a testament to the advanced engineering and technological prowess involved. Such technical nuances highlight the industry's deep-seated expertise in glass production.

In terms of application, float glass plates serve as a cornerstone for countless industries, indicating their authoritative stature. They are pivotal in architectural designs, automotive applications, and numerous decorative uses. Architects and designers often rely on the clarity and strength of float glass to implement stunning structures and facades, emphasizing the material's indispensability and authority in modern construction. Meanwhile, the automotive industry utilizes float glass in windshields and windows, a testament to its safety and durability—critical factors in the trustworthiness of the end products.

For end-users and industry professionals, the experience with float glass plates is unparalleled. The product's consistency and quality are often corroborated by client testimonials and long-term usage in demanding settings. End users recognize the unmatched transparency that float glass provides, making it a favored option in both functional and aesthetic applications. These user experiences underline the product's reliability and establish trustworthiness.

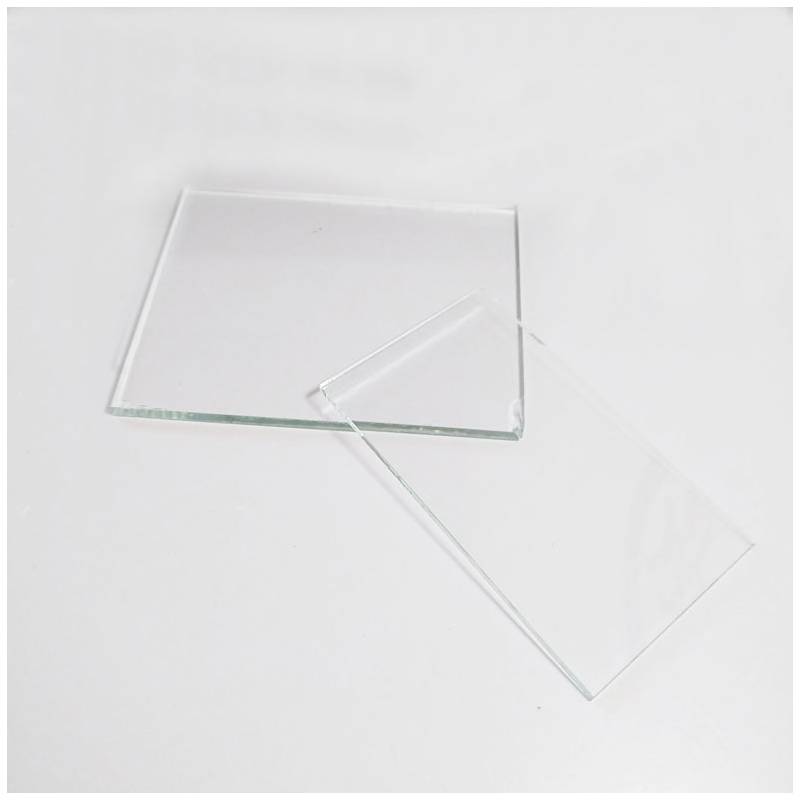

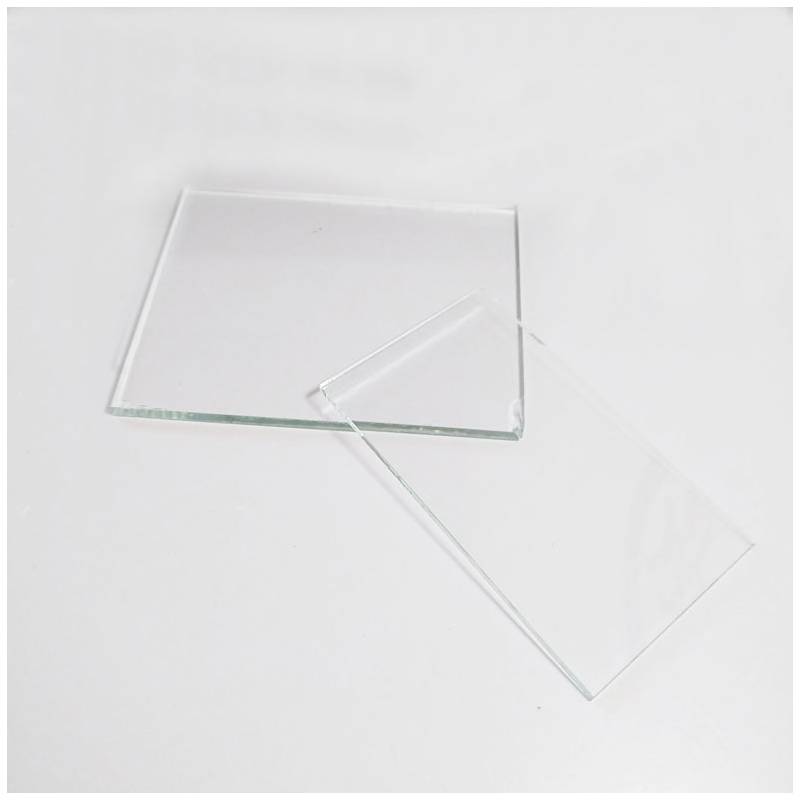

float glass plate

From an environmental perspective, float glass manufacturing has been at the forefront of sustainable practices in the glass industry. Manufacturers have increasingly invested in energy-efficient technologies and recycling processes, demonstrating a commitment to sustainability. They often engage in practices that reduce emissions and waste, aligning with global ecological standards. This sustainability aspect not only enhances the product's trust but also affirms the industry's dedication to environmentally friendly processes, reinforcing authority and expertise.

Further extending its authoritative stance, the production of float glass plates adheres to rigorous international standards and accreditations, ensuring quality and safety. Certifications from bodies like ISO and CE are commonplace, underscoring the reliability and credibility of these products for diverse applications. These standards are crucial for end-users seeking assurance of the product's excellence and durability.

Understanding the nuances of float glass plates can unlock new potential for businesses looking to leverage this product's benefits. Equipped with expertise in their features and a well-documented track record of performance, businesses can confidently incorporate float glass into their projects. The extensive knowledge surrounding float glass manufacturing and application readily positions it as a leader in innovative glass solutions.

In conclusion, float glass plates represent a synthesis of experience, expertise, authority, and trust. Their consistent role in varied applications underscores their value and dependability. By prioritizing quality and sustainability, float glass continues to solidify its rightful place as a foundational material in architecture and beyond. For industries and consumers alike, investing in float glass plates guarantees a product that is synonymous with excellence and reliability—a true reflection of the glass industry's advancements and commitments.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu