Understanding the Price of 3 8% Tempered Glass

Tempered glass, known for its strength and safety features, has become increasingly popular in various applications, from residential to commercial uses. Among the different types of tempered glass, 3 8% tempered glass is a specific product that has garnered attention for its unique properties and applications. In this article, we will explore the characteristics of 3 8% tempered glass and delve into the factors influencing its price.

What is 3 8% Tempered Glass?

Tempered glass is produced through a process of extreme heating and rapid cooling that increases its strength compared to standard glass. The designation 3 8% refers to the specific composition and properties of this type of glass. The percentages imply the chemical composition or specific enhancements made to the glass, delivering unique performance characteristics.

The term “tempered” signifies that the glass has been treated to withstand greater stress and thermal shock. This makes it a suitable choice for a variety of applications, including shower enclosures, glass doors, and facades, where safety and durability are paramount. The 3 8% tempered glass is particularly noted for its resistances to impact and temperature fluctuations, making it ideal for both residential and commercial environments.

Factors Influencing Price

1. Manufacturing Process

The production of tempered glass is a rigorous process that requires specialized equipment and skilled labor. The heating and cooling methods used can affect the overall cost. Advanced technologies and quality control measures add to the manufacturing expenses, and these costs are reflected in the price of the glass.

3 8 tempered glass price

2. Raw Materials

The cost of raw materials significantly impacts the price of tempered glass. Higher quality silicate materials may be used to produce glass with enhanced properties, and fluctuations in material costs can lead to variations in the final price. Supply chain issues and market demand for these materials also play a crucial role.

3. Thickness and Size

The thickness and dimensions of the glass panel affect its price. Generally, thicker glass (which is often safer and more insulating) costs more than thinner variants. Custom sizes or shapes also lead to increased pricing due to the additional cutting and handling required.

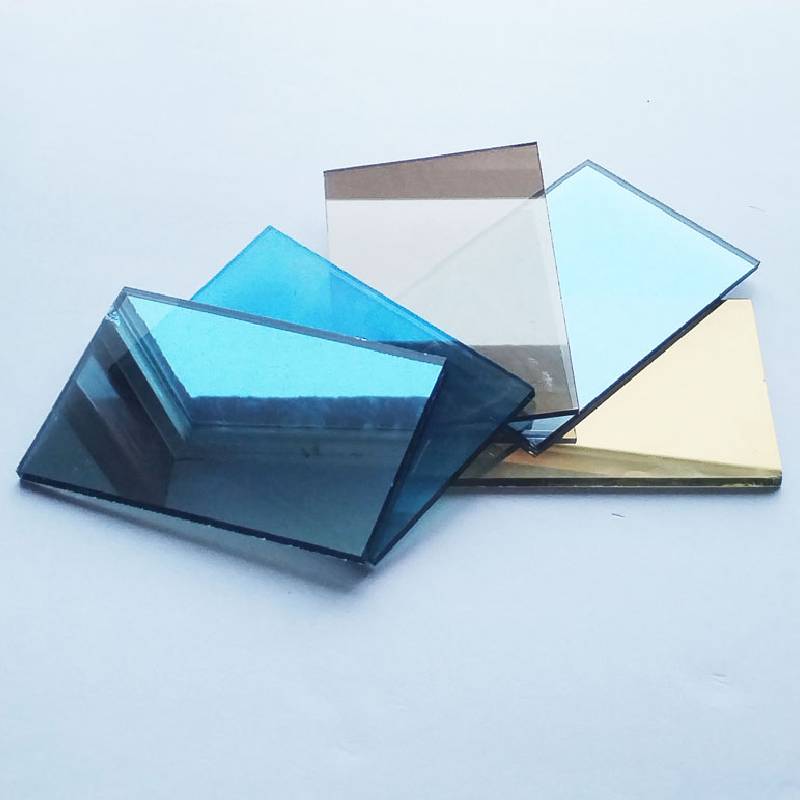

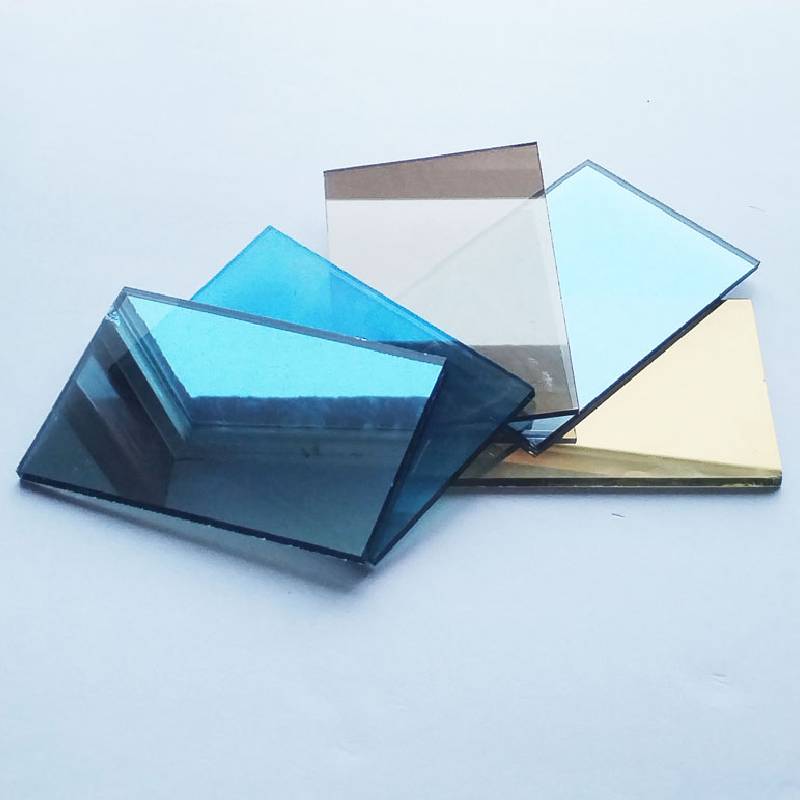

4. Thermal Treatments and Coatings

Additional treatments, such as coatings or tints that enhance privacy or reduce glare, can increase the cost of the glass. These features not only improve aesthetics but can also provide additional functionality, such as UV protection or energy efficiency.

5. Transportation and Installation

The logistics of transporting tempered glass can also influence its price. Given its fragility, transportation requires careful handling, which may lead to higher shipping costs. Moreover, professional installation might be required to ensure safety and compliance with building codes, adding to the overall expenses.

Conclusion

The price of 3 8% tempered glass is influenced by a multitude of factors, from manufacturing processes to raw materials and additional treatments. As consumers continue to value safety, durability, and aesthetic appeal in glass products, understanding these price influences is essential for making informed purchasing decisions. Whether for architectural projects or home renovations, the investment in tempered glass can provide lasting benefits, creating stunning and safe environments for years to come.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu