The Innovation of Clear Glass Factories Revolutionizing the Industry

In the modern era, the demand for glass products continues to grow across various industries, from construction and automotive to consumer goods and electronics. Among the different types of glass that have gained popularity, clear glass stands out due to its versatility, aesthetic appeal, and functional benefits. Clear glass factories play a pivotal role in meeting this demand, and their innovative approaches are revolutionizing the way glass is produced, manipulated, and utilized.

The Process of Clear Glass Production

The production of clear glass begins with the careful selection of raw materials. Silica sand, soda ash, and limestone serve as the primary components. In a clear glass factory, these materials are mixed in precise proportions to create a homogeneous batch. This mixture is then heated to extremely high temperatures in a furnace, typically exceeding 1,700 degrees Celsius (3,092 degrees Fahrenheit), where it melts into a molten glass state.

Once melted, the glass is formed into various shapes using a wide range of techniques, including blow molding, pressing, and forming. Advanced automation and robotics in modern clear glass factories enhance efficiency and precision in the manufacturing process. This not only reduces production costs but also minimizes waste, allowing for a more sustainable operation.

Technological Advancements

One of the most significant aspects of clear glass factories is their embrace of technological advancements. Automation technology ensures consistency in production, while computer-controlled systems allow for precise adjustments during the melting and forming processes. Innovations in energy efficiency have also become a priority. Many factories are adopting new furnace designs and insulation materials that significantly reduce energy consumption while maintaining high output levels.

Furthermore, advancements in material science have led to the development of specialty glasses. For instance, low-iron clear glass, which has enhanced transparency compared to traditional glass, is becoming increasingly popular in applications such as architectural glazing and solar panels. These specialty glasses are produced using advanced methods that minimize impurities, showcasing the factory's commitment to quality.

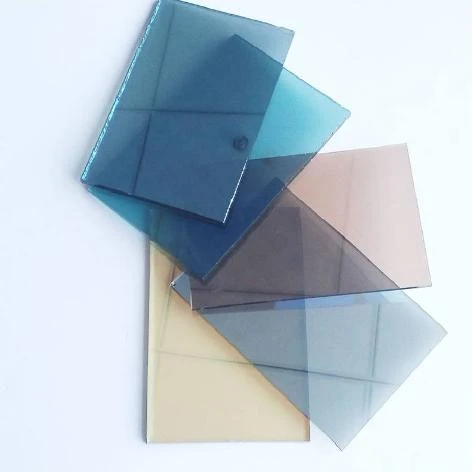

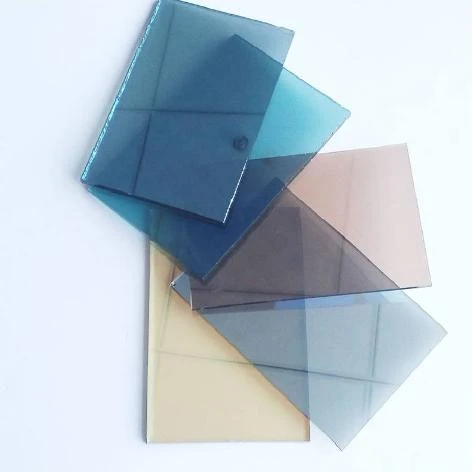

clear glass factory

Sustainability Efforts

The push for sustainability is a crucial aspect of modern clear glass factories. As consumers become more environmentally conscious, glass manufacturers are adopting eco-friendly practices to reduce their carbon footprint. One of the most impactful strategies is the emphasis on recycling. Clear glass is 100% recyclable without any loss in quality, making it an attractive option for both manufacturers and consumers. Many clear glass factories integrate recycled glass into their production processes, reducing the need for raw materials and lowering energy consumption.

Additionally, water conservation measures are being implemented across the industry to ensure that glass production has minimal environmental impact. The use of advanced filtration and recycling systems allows factories to reuse water in their operations, further promoting sustainability.

Applications and Market Demand

Clear glass is used in countless applications that range from everyday items such as bottles and jars to architectural features like windows and facades. In the automotive industry, clear glass is crucial for windshields and windows. The demand for lightweight, high-strength glass continues to rise, particularly in green building designs and energy-efficient constructions.

As the market evolves, clear glass factories are responding to changing consumer preferences by innovating their product lines. Smart glass technology, which can adjust its transparency based on light conditions or privacy needs, is an exciting development. This technology opens new avenues for energy savings in buildings and vehicles, presenting a growing market opportunity for glass manufacturers.

Conclusion

Clear glass factories are integral to supplying a wide range of industries with high-quality glass products. Their commitment to innovation, sustainability, and technological advancement positions them at the forefront of the glass manufacturing sector. As they continue to adapt to market demands and integrate eco-friendly practices, clear glass factories not only contribute to the economy but also play a vital role in promoting sustainable industrial practices. With ongoing developments in technology and materials science, the future of clear glass manufacturing looks bright, paving the way for a more sustainable and innovative industry.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu