Industry Trends and the Rise of Textured Glass

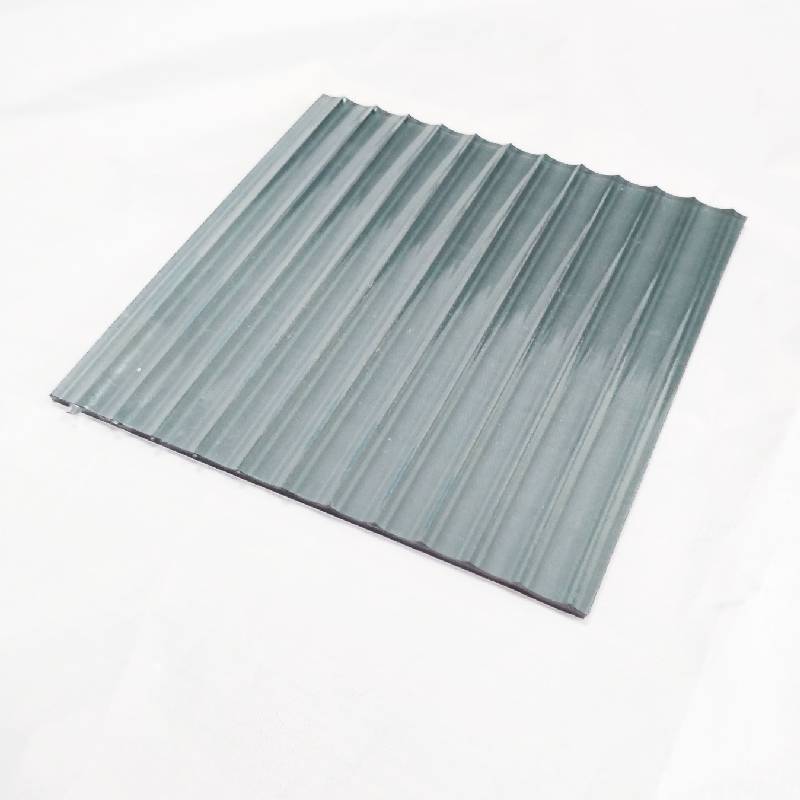

The architectural and interior design industries are continually evolving, with a growing emphasis on materials that blend aesthetic appeal with functional performance. In this dynamic landscape, textured glass has emerged as a prominent trend, offering innovative solutions for privacy, light diffusion, and decorative elements. Among these, the unique characteristics of moru glass texture have captured significant attention from B2B specifiers and designers.

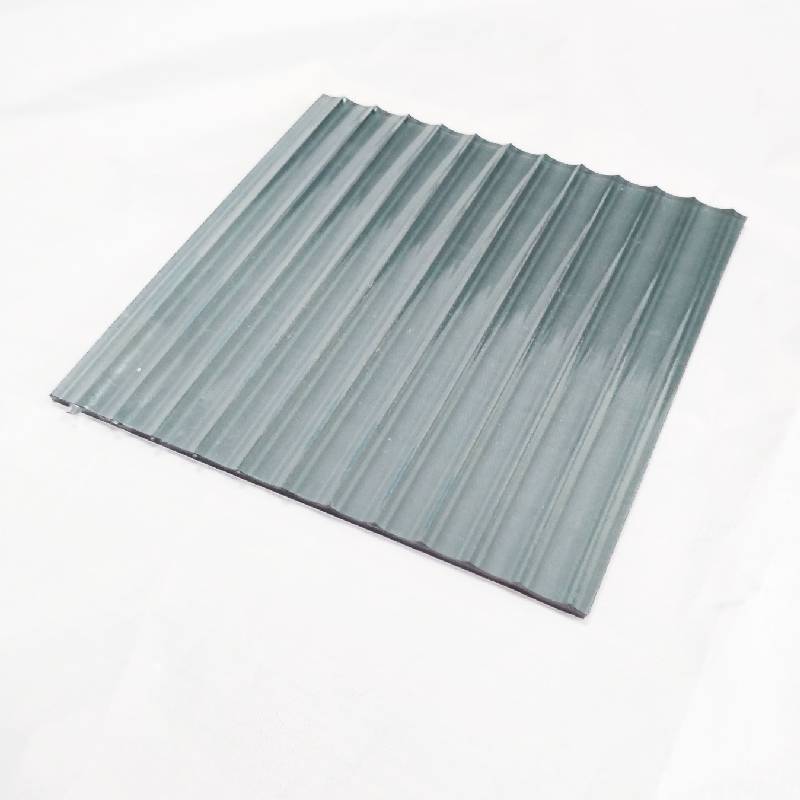

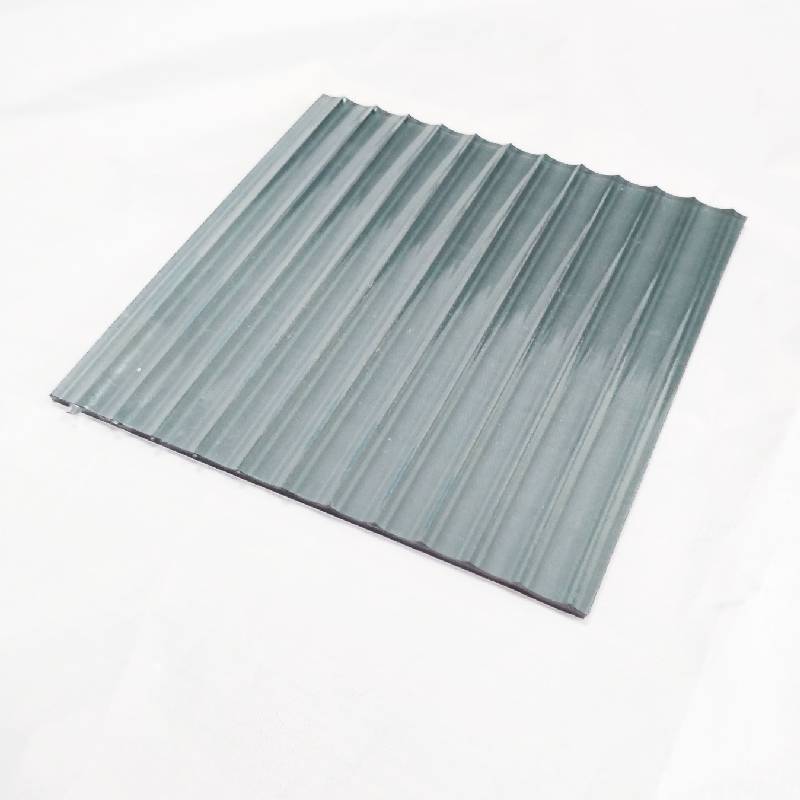

Modern design paradigms prioritize sustainability, biophilic elements, and the creation of versatile spaces. Moru glass, with its distinctive fluted or reeded pattern, addresses these demands by providing semi-transparency that maintains visual lightness while obscuring direct views. This inherent property makes it ideal for a multitude of applications, from sophisticated office partitions to elegant residential features. The demand for such specialized glass types is driven by an increasing need for both aesthetic differentiation and enhanced performance, including thermal insulation and acoustic dampening, pushing manufacturers to innovate beyond traditional flat glass offerings.

The market for specialty architectural glass is projected to grow substantially, influenced by global construction booms and a preference for high-value, aesthetically pleasing materials. Analysts forecast a Compound Annual Growth Rate (CAGR) of over 6% for the textured glass segment in the coming five years, underscoring the strategic importance of products like moru glass texture in meeting future market demands.

The Manufacturing Process of Moru Glass Texture

The production of 4mm Moru pattern fluted glass involves a precise and controlled manufacturing process, ensuring both aesthetic quality and structural integrity. This section outlines the key stages, material inputs, and quality assurance measures that define our product.

Process Flow Schematic:

- 1. Raw Material Preparation: High-quality silica sand, soda ash, limestone, and other additives are carefully measured and mixed. These materials are selected for their purity to ensure optical clarity and mechanical strength in the final moru glass product.

- 2. Melting: The batch mixture is fed into a furnace and heated to extremely high temperatures (typically 1500-1600°C) until it transforms into a molten glass state. Strict temperature control is crucial to eliminate air bubbles and ensure homogeneity.

- 3. Patterning (Calendaring/Rolling): The molten glass flows onto a casting table or between a set of rollers. One of these rollers is engraved with the distinctive Moru pattern. As the glass passes through, the pattern is imprinted onto its surface. This "rolling" or "calendaring" process creates the characteristic fluted moru glass texture. This is a critical step that defines the aesthetic and light-diffusing properties.

- 4. Annealing: The patterned glass sheet then enters an annealing lehr, where it is slowly cooled in a controlled manner. This process removes internal stresses, preventing cracking and enhancing the glass's overall durability and resistance to thermal shock.

- 5. Cutting and Finishing: Once annealed, the continuous glass ribbon is cut into desired sheet sizes. Subsequent processes may include edge grinding, polishing, or further processing like tempering or laminating to meet specific project requirements.

- 6. Quality Control and Testing: Throughout and after the manufacturing process, strict quality control measures are implemented. This includes visual inspection for defects, dimensional checks, and performance testing.

Key Specifications and Standards:

- Materials: Utilizes low-iron float glass for enhanced clarity before patterning, ensuring minimal color distortion.

- Manufacturing Processes: Primarily calendering/rolling for pattern creation, followed by precise annealing. Customization may involve CNC cutting for intricate shapes.

- Testing Standards: Our 4mm Moru pattern fluted glass adheres to international standards such as ISO 9001:2015 for quality management, EN 572-5 for patterned glass, and ANSI Z97.1 or EN 12150 for safety glazing when tempered.

- Service Life: When properly installed and maintained, moru glass offers a service life exceeding 30 years, resisting degradation from UV exposure and typical environmental factors.

- Target Industries & Advantages:

- Architecture & Interior Design: Offers aesthetic privacy, diffused light, and a modern, minimalist look for partitions, doors, and facades.

- Retail & Hospitality: Used for display cases, restaurant dividers, and hotel bathroom screens, providing elegance and subtle concealment.

- Office & Commercial Spaces: Enhances office acoustics, creates private meeting areas without sacrificing natural light, contributing to energy efficiency by maximizing daylighting.

- Water Supply & Drainage (Specialized applications): While less direct, its use in technical control room windows or aesthetic partitioning in public facilities can leverage its durability and ease of cleaning, implicitly benefiting energy saving through improved daylighting and reducing lighting loads. Corrosion resistance is inherent to glass.

Technical Specifications: 4mm Moru Pattern Fluted Glass

Understanding the precise technical parameters of our 4mm Moru pattern fluted glass is crucial for architects, engineers, and designers. The following table provides a detailed overview of its key specifications, demonstrating its suitability for demanding B2B applications.

Product Specification Table:

| Parameter |

Value / Description |

Standard / Test Method |

| Nominal Thickness |

4 mm (±0.2 mm) |

EN 572-5 / ASTM C1036 |

| Pattern Depth |

0.8 - 1.2 mm |

Internal Measurement |

| Light Transmittance (Visible) |

75-80% |

ISO 9050 |

| Shading Coefficient (SC) |

0.85 (single pane) |

NFRC 200 |

| U-value (W/m²K) |

~5.8 (single pane) |

EN 673 |

| Reflectance (Visible) |

~8% |

ISO 9050 |

| Density |

2.5 g/cm³ |

ISO 1183 |

| Hardness (Mohs) |

6-7 |

Industry Standard |

| Max Sheet Size |

2440 mm x 3660 mm (customizable) |

Manufacturing Capability |

These specifications highlight the optimal balance between visual aesthetics and performance that moru glass texture offers. Its moderate light transmittance ensures bright interiors while providing desired privacy, and its inherent durability makes it a reliable choice for long-term installations.

Application Scenarios and Case Studies

The versatility of moru glass makes it an invaluable material across a spectrum of B2B applications, from commercial interiors to specialized industrial settings. Its ability to diffuse light, provide subtle privacy, and add a tactile aesthetic elevates various environments.

Typical Applications:

- Interior Partitions: Ideal for office spaces, conference rooms, and open-plan areas where visual separation is desired without blocking natural light. It offers acoustic benefits, reducing sound transmission.

- Shower Screens and Bathroom Doors: Provides essential privacy in high-moisture environments, with its textured surface resisting water spots and requiring minimal maintenance.

- Cabinetry and Furniture Inserts: Adds a sophisticated touch to kitchen cabinets, wardrobe doors, and display units, obscuring contents while allowing light to pass through.

- Doors and Entrances: Used in both internal and external doors, offering security, privacy, and an inviting aesthetic.

- Balustrades and Railings: When tempered, moru glass provides safety and an elegant design element for staircases, balconies, and mezzanines.

- Retail Displays and Signage: Creates an intriguing backdrop for product displays or adds a unique texture to brand signage, drawing customer attention.

Application Case Studies:

Our track record with esteemed clients underscores the practical advantages and aesthetic impact of Moru glass.

Case Study 1: Corporate Office Renovation

Client: Global Tech Solutions, Inc.

Challenge: To create private meeting pods within an open-plan office layout without diminishing natural light or visual spaciousness.

Solution: Installed custom-sized 4mm tempered Moru pattern fluted glass panels for all meeting room walls and doors.

Outcome: The moru glass texture successfully diffused light, maintaining a bright atmosphere, while offering the necessary visual privacy for focused work. Employee feedback cited improved concentration and appreciation for the modern aesthetic. The client noted an improvement in ambient lighting, reducing the need for artificial light during daytime hours, thus contributing to energy savings.

Case Study 2: Boutique Hotel Bathroom Design

Client: The Zenith Suites Hotel

Challenge: To design luxurious en-suite bathrooms that offered privacy for guests while maintaining a high-end, contemporary aesthetic. Traditional frosted glass was deemed too opaque and lacking in character.

Solution: Utilized 4mm Moru pattern fluted glass for shower enclosures and partition walls separating sleeping and bathing areas. The glass was heat-strengthened for safety.

Outcome: The hotel received rave reviews for its bathroom designs. The moru glass provided an elegant, diffused barrier, allowing light to flow freely and making the spaces feel larger and more open, without compromising guest privacy. Its inherent corrosion resistance to moisture and ease of cleaning also contributed to lower operational costs.

Technical Advantages of Moru Glass Texture

Beyond its undeniable aesthetic appeal, the 4mm Moru pattern fluted glass offers a range of technical advantages that make it a superior choice for various architectural and design applications.

- Enhanced Privacy with Diffused Light: Unlike opaque materials, moru glass texture provides a sophisticated level of privacy by distorting images without completely blocking light. This means spaces remain bright and airy, reducing the need for artificial lighting and contributing to energy savings. The vertical flutes effectively obscure direct views while allowing approximately 75-80% visible light transmittance.

- Acoustic Performance: The textured surface of moru glass can contribute to improved acoustic dampening compared to clear flat glass of the same thickness. The irregularities in the surface help scatter sound waves, reducing echo and reverberation, making it suitable for quiet zones in offices or residential areas.

- Durability and Safety: Manufactured from robust glass materials, our Moru patterned glass offers excellent durability. It can be further processed into tempered (toughened) glass, significantly increasing its strength against impact (up to 5 times stronger than annealed glass) and ensuring that, if broken, it shatters into small, blunt pieces, enhancing safety in accordance with EN 12150 standards.

- Corrosion Resistance: As a silica-based product, glass is inherently resistant to most chemicals, acids, and alkalis, making moru glass ideal for environments where chemical exposure or high humidity might degrade other materials. This includes applications in laboratories, cleanrooms, and moisture-prone areas like bathrooms.

- Ease of Maintenance: The smooth fluted surface, despite its texture, is non-porous and easy to clean, resisting stains, mold, and mildew growth. This makes it a hygienic choice for healthcare, hospitality, and public sector applications.

- Versatility in Processing: Beyond its inherent properties, moru glass can undergo various secondary treatments, including laminating for enhanced security, sandblasting for custom designs, or silvering for mirror applications, expanding its functional scope significantly.

Vendor Comparison: Choosing the Right Supplier for Moru Glass

Selecting a supplier for specialized glass like 4mm Moru pattern fluted glass requires careful consideration of factors beyond just price. Quality, reliability, customization capabilities, and adherence to industry standards are paramount for B2B procurement.

Moru Glass Supplier Comparison Table:

| Feature |

Our Company (e.g., ShZ R Glass) |

Typical Competitor A |

Typical Competitor B |

| Product Quality Certifications |

ISO 9001:2015, EN 572-5, CE |

ISO 9001 |

Basic QC checks |

| Customization Capabilities |

Extensive (size, shape, thickness, processing: tempering, laminating, CNC cut) |

Limited (standard sizes, basic tempering) |

Minimal (stock items only) |

| Lead Time (Standard Orders) |

15-20 business days |

20-30 business days |

30-45 business days |

| After-Sales Support |

Dedicated B2B team, technical assistance, warranty claims |

Standard customer service |

Limited email support |

| Experience in B2B Projects |

Over 15 years, numerous large-scale projects |

5-10 years, some small-medium projects |

Less than 5 years, mainly distributors |

| Pricing Competitiveness |

Premium value for certified quality and service |

Mid-range, compromises on customization |

Lower, but limited range and support |

This comparison underscores our commitment to delivering superior quality, comprehensive customization, and reliable support for all moru glass requirements. Our long-standing industry presence and robust certifications ensure that clients receive products that meet stringent international benchmarks.

Customized Solutions and Partner Clients

Recognizing that every B2B project has unique demands, we offer extensive customization options for our 4mm Moru pattern fluted glass. Our expertise allows us to tailor solutions that perfectly integrate with diverse design and functional requirements.

Customization Capabilities:

- Thickness & Size: While 4mm is standard, we can supply moru glass in various thicknesses to meet specific structural or safety ratings. Custom dimensions up to 2440 mm x 3660 mm are available, ensuring minimal wastage and seamless integration.

- Edgework: Options include polished edges, beveled edges, or specific grinding for unique aesthetic or installation requirements.

- Processing & Fabrication: Our facilities are equipped for advanced processing such as:

- Tempering (Toughening): For enhanced safety and strength in high-traffic areas or applications requiring impact resistance.

- Laminating: Combining two or more glass sheets with an interlayer (e.g., PVB or SGP) for superior security, acoustic insulation, and UV protection.

- Holes & Cut-outs: Precision drilling and cutting for hardware, fittings, and intricate designs using CNC machinery.

- Pattern Direction: The vertical flutes of moru glass can be oriented as per design specifications (vertical or horizontal).

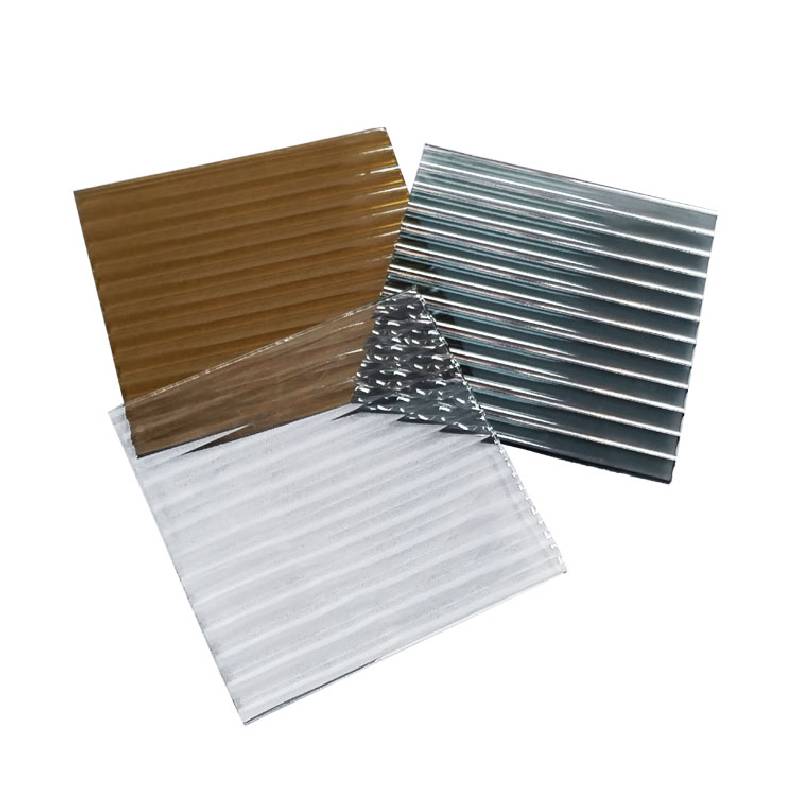

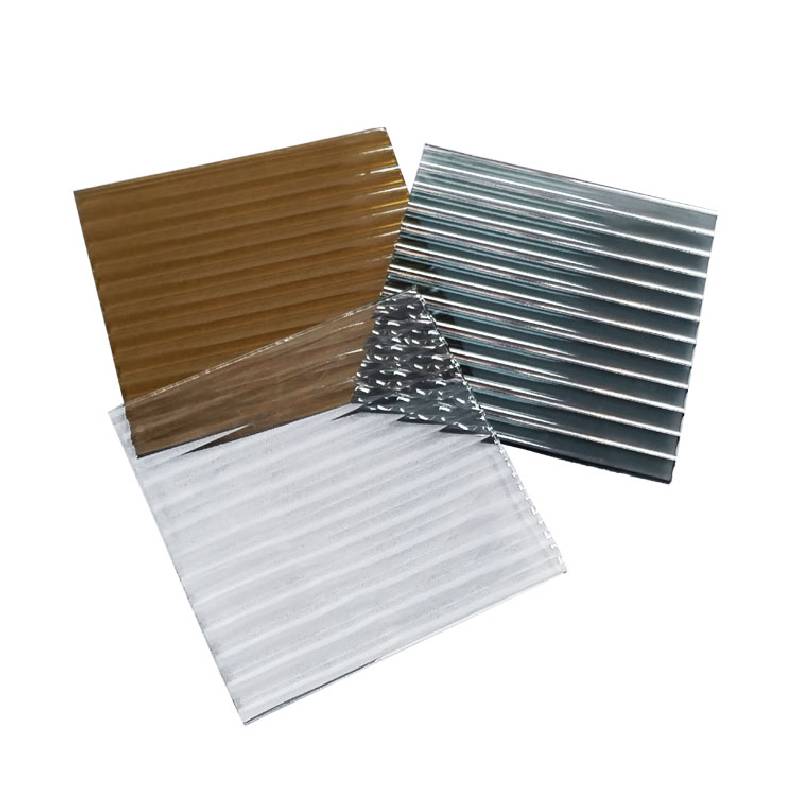

- Coating & Tinting: While inherently clear, options for low-emissivity (low-e) coatings for thermal performance or subtle tints can be explored for specific project needs.

Authoritative References & Partner Clients:

Our commitment to quality is reinforced by our adherence to international standards and our long-standing relationships with leading firms. We are an ISO 9001:2015 certified manufacturer, ensuring rigorous quality management systems from raw material sourcing to final product delivery. Our products meet or exceed EN, ASTM, and ANSI standards for various glass applications.

Over the past 15 years, we have partnered with renowned architectural firms, construction companies, and interior design agencies on a multitude of high-profile projects. Our client portfolio includes collaborations with:

- "Grand City Towers" Development: Provided custom-sized Moru patterned glass for luxury apartment shower enclosures and common area partitions.

- "Innovate Hub" Co-working Space: Supplied large format, tempered moru glass panels for flexible office dividers, enhancing both aesthetics and acoustic comfort.

- "Regal Hotel Chain" Refurbishment: Delivered specialized fluted glass for bathroom partitions and decorative screens in multiple hotel locations, adhering to stringent hospitality safety and design standards.

Our dedication to quality and client satisfaction has established us as a trusted partner in the global glass industry.

Trustworthiness: FAQ, Lead Time, Warranty, and Support

Establishing trust with our B2B partners is paramount. We believe in transparency and providing comprehensive support throughout the entire project lifecycle, from initial inquiry to post-installation.

Frequently Asked Questions (FAQ):

Q1: Can 4mm Moru pattern fluted glass be tempered or laminated?

A1: Yes, absolutely. Our 4mm Moru pattern fluted glass can be subjected to thermal tempering to enhance its strength and safety. It can also be laminated with various interlayers (PVB, SGP) to create safety glass, improve acoustic performance, or add specific visual effects.

Q2: What are the best cleaning practices for moru glass?

A2: Due to its non-porous surface, moru glass is relatively easy to clean. We recommend using a soft cloth or sponge with warm water and a mild, non-abrasive glass cleaner. Avoid harsh chemicals or abrasive pads which can damage the surface.

Q3: Is moru glass suitable for exterior applications?

A3: While primarily used for interiors due to its aesthetic and privacy benefits, when properly processed (e.g., tempered and/or laminated, potentially with a low-e coating), moru glass can be integrated into exterior architectural elements where diffuse light and obscured views are desired, such as curtain walls or unique facade features. It is naturally resistant to UV degradation.

Q4: What is the typical lead time for custom moru glass orders?

A4: For standard 4mm Moru pattern fluted glass, the lead time is typically 15-20 business days from order confirmation and deposit. For complex custom specifications (e.g., large volumes, specialized processing, unique shapes), lead times may extend to 25-35 business days. We always provide an estimated delivery schedule upon quotation.

Lead Time and Fulfillment:

Our streamlined production and logistics ensure efficient order fulfillment.

- Order Processing: Dedicated account managers handle all B2B inquiries, providing detailed quotations and technical consultations.

- Production Schedule: Upon final approval of drawings and payment terms, orders are seamlessly integrated into our manufacturing pipeline. Regular updates on production status are provided.

- Packaging & Shipping: All glass products are expertly packaged in sturdy crates or frames, suitable for international shipping, minimizing damage risks. We work with trusted logistics partners to ensure timely and secure delivery worldwide.

Warranty Commitments:

We stand behind the quality of our 4mm Moru pattern fluted glass with a comprehensive warranty.

- Material and Workmanship: We offer a 5-year warranty against defects in material and manufacturing workmanship under normal use and service conditions.

- Performance Guarantees: Our glass is guaranteed to meet the published technical specifications. Any deviations falling outside the specified tolerances will be addressed promptly.

- Claim Process: In the unlikely event of a warranty claim, our dedicated support team will guide you through a straightforward and efficient resolution process.

Customer Support Information:

Our expert team is always ready to assist with your project needs.

- Technical Consultation: Our engineers and product specialists are available to provide in-depth technical advice, assist with specification writing, and offer solutions for complex design challenges involving moru glass.

- Project Management: For large-scale orders, a dedicated project manager ensures seamless communication and coordination from order inception to delivery.

- Contact Us:

- Email: sales@shzrglass.com

- Phone: +86-XXX-XXXX-XXXX (placeholder)

- Website: www.shzrglass.com

Your project's success is our priority, and our comprehensive support system is designed to facilitate smooth and effective collaboration.

Conclusion

The 4mm Moru pattern fluted glass represents a confluence of sophisticated design, robust technical performance, and sustainable manufacturing practices. Its ability to elegantly diffuse light, provide subtle privacy, and enhance acoustic comfort positions it as a premier choice for discerning B2B clients in the architectural and interior design sectors. From its meticulous production process adhering to international standards to its versatile application across diverse environments, moru glass texture offers tangible advantages that contribute to both aesthetic excellence and operational efficiency. By choosing a reputable supplier, businesses can ensure access to high-quality, customized solutions backed by extensive industry expertise and unwavering support.

References

- International Organization for Standardization. ISO 9001:2015 - Quality management systems - Requirements.

- European Committee for Standardization. EN 572-5: Glass in building - Basic soda-lime silicate glass products - Part 5: Patterned glass.

- National Fenestration Rating Council. NFRC 200: Procedure for Determining Fenestration Product Solar Heat Gain Coefficient and Visible Transmittance at Normal Incidence.

- ASTM International. ASTM C1036-16: Standard Specification for Flat Glass.

- Glass Magazine. "Architectural Glass Market Outlook 2023-2028."

Afríku

Afríku  albanska

albanska  amharíska

amharíska  arabíska

arabíska  Armenska

Armenska  Aserbaídsjan

Aserbaídsjan  baskneska

baskneska  hvítrússneska

hvítrússneska  bengalska

bengalska  bosníska

bosníska  búlgarska

búlgarska  katalónska

katalónska  Cebuano

Cebuano  korsíkanskt

korsíkanskt  króatíska

króatíska  tékkneska

tékkneska  danska

danska  hollenska

hollenska  Enska

Enska  esperantó

esperantó  eistneska, eisti, eistneskur

eistneska, eisti, eistneskur  finnska

finnska  franska

franska  frísneska

frísneska  galisíska

galisíska  georgískt

georgískt  þýska, Þjóðverji, þýskur

þýska, Þjóðverji, þýskur  grísku

grísku  Gújaratí

Gújaratí  Haítískt kreóla

Haítískt kreóla  hausa

hausa  hawaiískur

hawaiískur  hebreska

hebreska  Neibb

Neibb  Miaó

Miaó  ungverska, Ungverji, ungverskt

ungverska, Ungverji, ungverskt  íslenskur

íslenskur  igbó

igbó  indónesíska

indónesíska  írska

írska  ítalska

ítalska  japönsku

japönsku  javanska

javanska  Kannada

Kannada  kasakska

kasakska  Khmer

Khmer  Rúanda

Rúanda  kóreska

kóreska  Kúrda

Kúrda  Kirgisi

Kirgisi  TB

TB  latína

latína  lettneska

lettneska  litháískur

litháískur  Lúxemborg

Lúxemborg  makedónska

makedónska  Malgashi

Malgashi  malaíska

malaíska  Malajalam

Malajalam  maltneska

maltneska  Maori

Maori  Marathi

Marathi  mongólska

mongólska  Mjanmar

Mjanmar  nepalska

nepalska  norska

norska  norska

norska  oksítanska

oksítanska  Pastó

Pastó  persneska

persneska  pólsku

pólsku  portúgalska

portúgalska  Púndjabí

Púndjabí  rúmenska

rúmenska  Rússneskt

Rússneskt  Samósk

Samósk  skosk gelíska

skosk gelíska  serbneska

serbneska  Enska

Enska  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  slóvakíska

slóvakíska  slóvenska

slóvenska  sómalska

sómalska  spænska, spænskt

spænska, spænskt  Sundaneskir

Sundaneskir  svahílí

svahílí  sænsku

sænsku  Tagalog

Tagalog  Tadsjikska

Tadsjikska  tamílska

tamílska  Tatar

Tatar  telúgú

telúgú  Tælensk

Tælensk  tyrkneska

tyrkneska  Túrkmenska

Túrkmenska  úkraínska

úkraínska  Úrdú

Úrdú  Uighur

Uighur  úsbekskur

úsbekskur  Víetnamska

Víetnamska  velska

velska  Hjálp

Hjálp  jiddíska

jiddíska  Jórúba

Jórúba  Zulu

Zulu