The Float Glass Factory A Window into the Future

Float glass, a remarkable material that has transformed the architectural landscape, is produced through a fascinating process that balances science, precision, and craftsmanship. Float glass factories represent a critical facet of modern manufacturing, where innovation meets sustainability, delivering products that not only enhance aesthetic appeal but also improve energy efficiency in buildings.

The Float Glass Manufacturing Process

The production of float glass begins with raw materials such as silica sand, soda ash, and limestone. These ingredients are carefully selected for their purity and quality because any contamination can affect the final product's clarity and strength. Once the materials are prepared, they are mixed and heated in a furnace at temperatures exceeding 1600 degrees Celsius. This intense heat causes the mixture to melt into a molten glass.

The molten glass is then poured onto a bed of molten tin. This is the essence of the float glass process the glass naturally spreads out over the tin due to its lower density and subsequently forms a smooth, flat surface. The setup allows for the production of large sheets of glass that are uniform in thickness and free from wavy distortions. This method, invented in the 1950s, revolutionized the glass industry and allowed for the mass production of high-quality glass for windows and displays.

As the glass moves through the cooling process, it is carefully monitored to ensure that it solidifies evenly. This stage is crucial because any imperfections can lead to significant issues in subsequent applications. Once cooled, the glass is cut into desired sizes and shapes, ready for further processing or distribution.

Innovations and Sustainability

Float glass factories are at the forefront of technological innovations that strive to reduce energy consumption and minimize waste. Many modern facilities utilize state-of-the-art technology to optimize the melting process, employing regenerative burners that recycle heat, thereby increasing energy efficiency. Some factories integrate renewable energy sources, such as solar or wind power, to reduce the carbon footprint associated with glass production.

Another significant trend in float glass manufacturing is the rise of specialized coatings that enhance the glass's performance. Low-emissivity (low-e) coatings, for example, improve thermal insulation, reflecting heat back into a building during winter and keeping it cool in summer. This innovation not only contributes to energy savings but also aids in reducing greenhouse gas emissions, aligning with global sustainability goals.

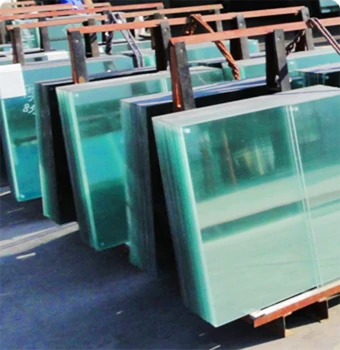

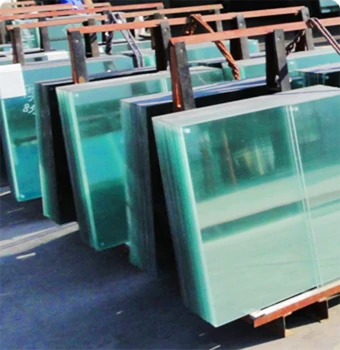

float glass factory

The Role of Float Glass in Architecture

The impact of float glass extends far beyond its manufacturing process; it plays an essential role in contemporary architecture. Large glass facades have become a hallmark of modern design, allowing for natural light to flood indoor spaces while offering glimpses of the outside world. This seamless integration of indoor and outdoor environments fosters well-being and enhances the aesthetic value of buildings.

Moreover, float glass is used in various applications, from commercial skyscrapers to residential homes, and even in automotive industries. Its versatility is unmatched, available in various thicknesses and finishes, enabling architects and designers to push the boundaries of creativity. As cities evolve and the emphasis on sustainable design grows, float glass will remain central to innovative building practices.

Challenges and Future Directions

Despite the many advancements in float glass manufacturing, challenges remain. The production process is still energy-intensive, and the demand for raw materials, especially silica, raises concerns about environmental impact and resource depletion. Looking ahead, the industry must explore alternative materials and recycling processes to create a more circular economy.

Furthermore, as digitalization transforms industries, float glass factories will likely adopt smart manufacturing techniques, incorporating automation and data analytics to enhance efficiency and quality control. The future promises even more significant advancements, as manufacturers strive to create glass products that meet the evolving needs of society while prioritizing sustainability.

Conclusion

In conclusion, float glass factories not only serve as vital production hubs for this essential material but also exemplify the marriage of technology, sustainability, and design. With ongoing innovations and a commitment to eco-friendly practices, the float glass industry is poised to shape the living and working spaces of the future, proving that clear glass can indeed reflect a clearer vision for our environment.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu