The Float Glass Manufacturing Industry An Overview

In recent years, the float glass manufacturing industry has witnessed significant growth, driven by advancements in technology and increasing demand from various sectors. Float glass, known for its clarity and uniform thickness, is primarily utilized in windows, facades, mirrors, and a variety of architectural applications. This article delves into the key processes, market trends, and challenges faced by float glass manufacturers.

Understanding the Float Glass Process

The float glass manufacturing process was first developed in the 1950s and has since become the predominant method for producing flat glass. The process begins with the melting of raw materials, which typically include silica sand, soda ash, and limestone, in a furnace at temperatures exceeding 1,700 degrees Celsius. The molten glass is then carefully poured onto a bath of molten tin, which allows it to spread out evenly and form a flat, smooth surface. The glass solidifies as it moves along the tin bath, and once cooled, it is cut into various sizes for distribution.

One of the critical advantages of this method is the high quality of glass produced, with excellent optical clarity and minimal surface imperfections. Additionally, advancements in technology have enabled manufacturers to produce low-emissivity (Low-E) glass, which significantly improves thermal insulation and energy efficiency. This innovation is particularly beneficial in residential and commercial buildings, where energy consumption is a growing concern.

Market Applications and Trends

The demand for float glass is primarily driven by the construction and automotive industries. In the construction sector, float glass is employed in windows and facades to enhance aesthetics while providing insulation. The automotive industry utilizes float glass for windshields and windows, where safety and clarity are paramount. The rising popularity of energy-efficient buildings and vehicles is expected to further boost demand for float glass, particularly Low-E and tinted variants that offer additional benefits like UV protection and glare reduction.

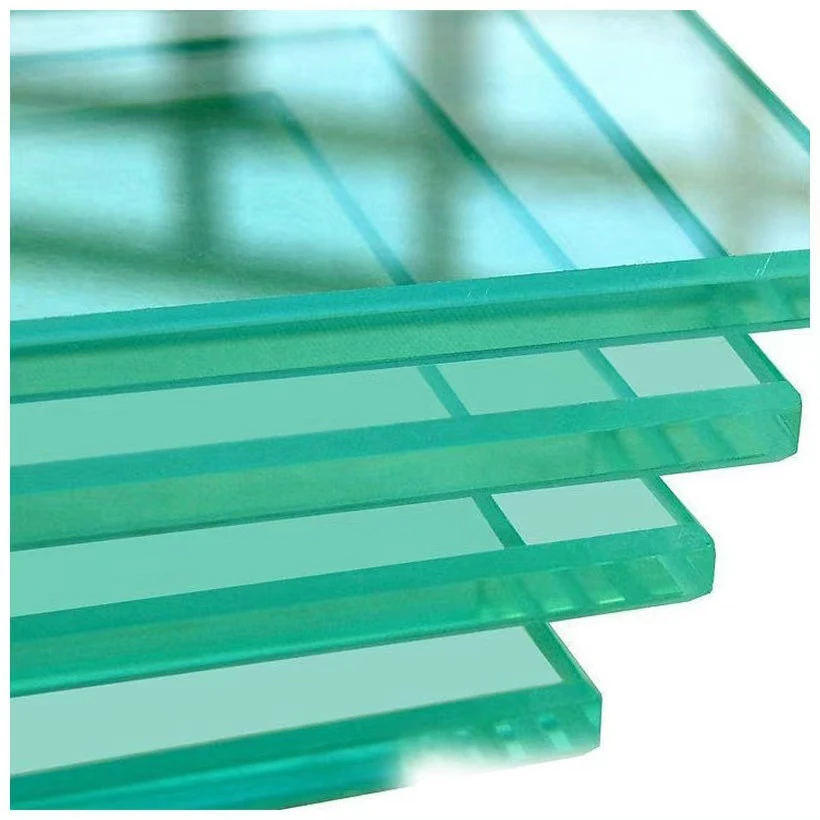

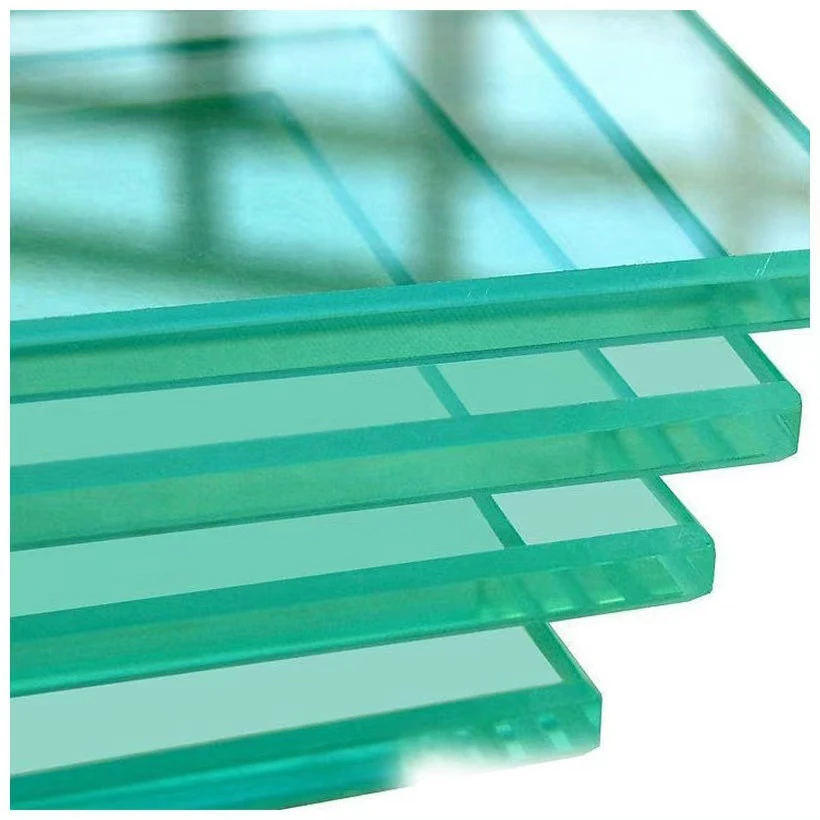

float glass manufacturers

Moreover, float glass manufacturers are increasingly focusing on sustainable practices. The industry's shift towards environmentally friendly production methods has resulted in the recycling of glass products and the use of renewable energy sources in manufacturing processes. This trend not only reduces the carbon footprint but also aligns with global sustainability goals.

Challenges Facing the Industry

Despite the promising growth and innovation within the float glass manufacturing sector, several challenges remain. One significant issue is the volatile prices of raw materials, primarily due to fluctuations in natural gas and silica sand availability. Such fluctuations can affect production costs and profit margins, forcing manufacturers to adapt quickly to market changes.

In addition, the competitive landscape is intensifying, with numerous manufacturers vying for market share. This competition pressures companies to innovate continuously and optimize their production processes to maintain profitability. Automation and digitalization are becoming crucial in addressing these challenges, as manufacturers leverage advanced technologies to improve efficiency and reduce operational costs.

Conclusion

The float glass manufacturing industry is poised for a bright future, characterized by innovation, sustainability, and a growing market. As manufacturers adapt to changing consumer demands and technological advancements, they will play a vital role in supplying high-quality glass products for construction and automotive applications. By addressing the challenges of raw material costs and competitive pressures, float glass manufacturers can continue to thrive in this dynamic marketplace. The ongoing emphasis on energy efficiency and sustainability will further shape the industry's direction, ensuring its relevance in a rapidly evolving world.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu