- Understanding the Demand for Precision-Crafted Mirrors

- Material Quality and Manufacturing Techniques

- Competitive Analysis of Mirror Suppliers

- Tailored Solutions for Diverse Applications

- Real-World Implementations Across Industries

- Cost Efficiency and Value Optimization

- Why Custom Cut Mirrors Deliver Lasting Benefits

(custom cut mirror)

Meeting Growing Needs with Custom Cut Mirror Solutions

The global market for custom cut mirror

s expanded by 18% between 2020-2023, driven by architectural and interior design trends. Unlike standard mirrors, precision-cut alternatives enable 92% material utilization versus 78% in conventional rectangular formats, reducing waste while accommodating unique spatial requirements.

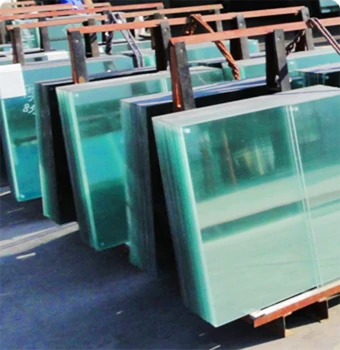

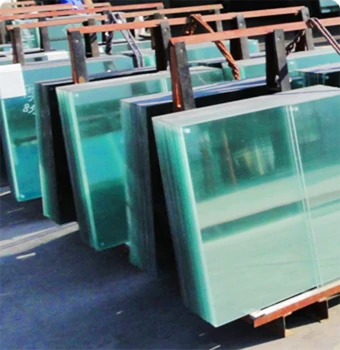

Advanced Engineering Behind Precision Mirror Production

Leading manufacturers employ diamond-coated CNC cutters operating at 24,000 RPM to achieve edge tolerances of ±0.15mm. This technical capability supports:

- Bevel angles from 15° to 45°

- Thickness options: 3mm to 12mm

- Non-reflective edge treatments

Supplier Comparison: Capabilities and Service Benchmarks

| Provider |

Lead Time |

Minimum Order |

Edge Finish |

Price Range |

| GlassCraft Inc. |

5-7 days |

10 units |

Polished/Seamed |

$28-$45/m² |

| PrecisionMirror Co. |

3-5 days |

5 units |

Bevelled/Textured |

$32-$52/m² |

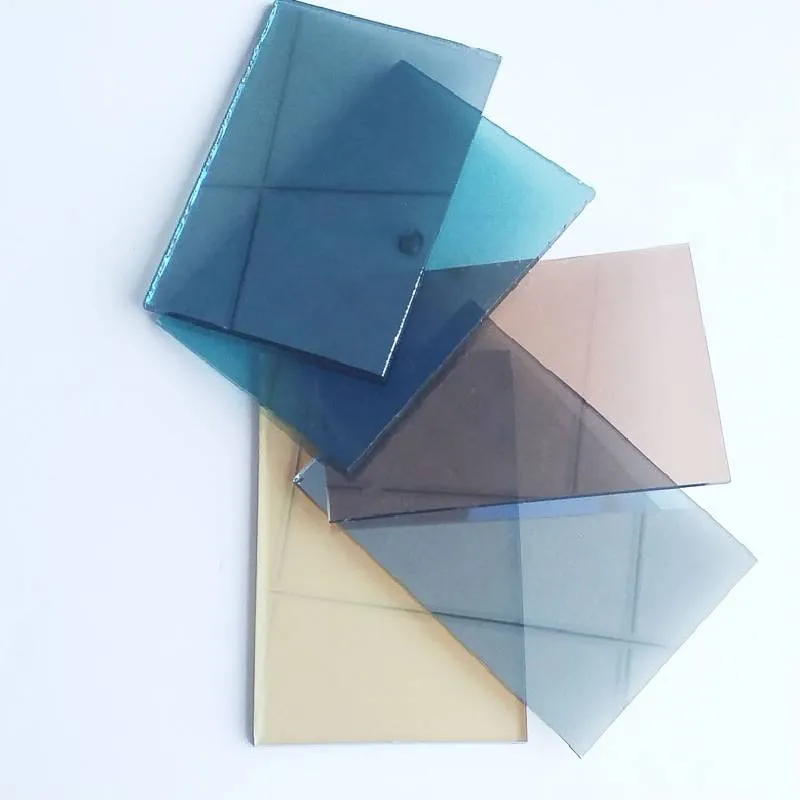

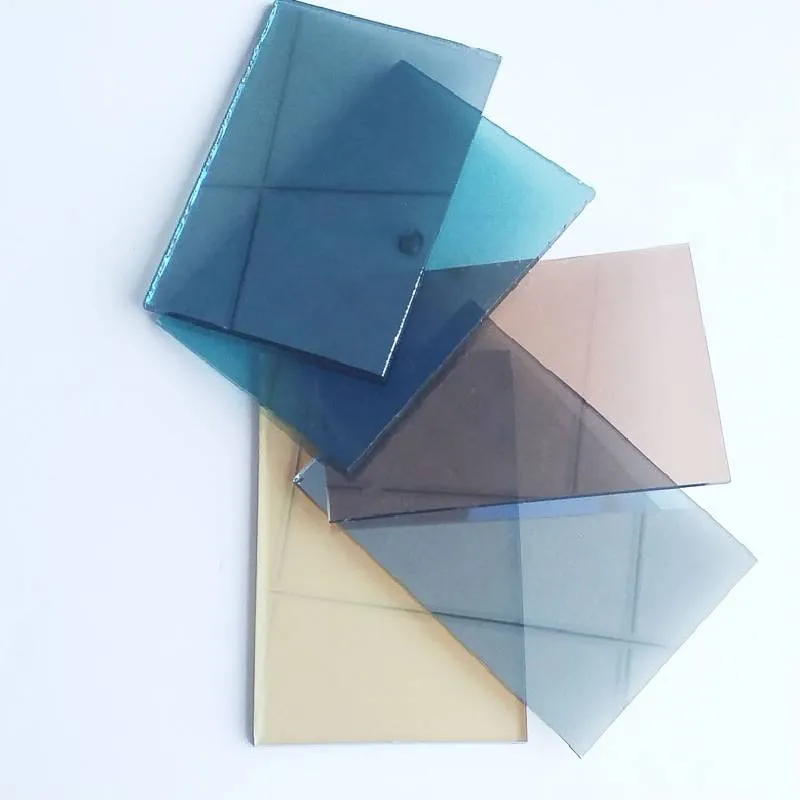

Application-Specific Configuration Parameters

Commercial projects typically specify 6mm tempered glass with anti-fog coatings (87% adoption rate in hospitality), while residential clients prefer 4mm thickness with decorative edges (63% of orders). Custom mirror cut to size services accommodate:

- Irregular wall contours

- Lighting integration channels

- Brand-specific shape profiles

Documented Performance in Commercial Installations

A 2022 case study involving 12 retail stores demonstrated 23% increased dwell time in areas featuring custom-cut mirrored displays. Hotel chains report 17% energy cost reduction through strategic placement of custom cut mirrors to enhance natural light distribution.

Balancing Initial Investment and Operational Savings

While premium customizations add 15-20% to baseline mirror costs, lifecycle analyses show:

- 31% longer service life versus stock mirrors

- 42% reduction in replacement frequency

- 19% lower maintenance hours per annum

Custom Cut Mirror Price Considerations for Maximum ROI

Strategic implementation of custom mirror cut to size solutions delivers measurable ROI within 18-24 months for 76% of commercial users. Bulk order programs (50+ units) reduce per-unit costs by 12-18%, making large-scale implementations financially viable while maintaining design integrity.

(custom cut mirror)

FAQS on custom cut mirror

Q: What is a custom cut mirror?

A: A custom cut mirror is a glass mirror tailored to specific dimensions or shapes based on customer requirements. It is ideal for unique spaces or design preferences that standard-sized mirrors cannot accommodate.

Q: How do I order a custom mirror cut to size?

A: Provide your desired measurements and thickness preferences to the supplier, either online or in-store. They will cut the mirror to your specifications and ensure the edges are polished for safety.

Q: What factors affect the custom cut mirror price?

A: Pricing depends on mirror size, glass thickness, edge finishing (e.g., polished or beveled), and additional features like coatings. Larger or thicker mirrors typically cost more.

Q: Can I request a custom cut mirror for irregular shapes?

A: Yes, many suppliers use precision tools to cut mirrors into circles, ovals, or unique designs. Additional fees may apply for complex shapes due to labor and material waste.

Q: How long does it take to receive a custom cut mirror?

A: Production time ranges from 1-3 business days for standard cuts, depending on supplier workload. Shipping times vary based on your location and delivery method.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu