The Flat Glass Production A Comprehensive Overview

Flat glass, commonly referred to as sheet glass, is an essential material used across various industries, from construction to automotive manufacturing. Its versatility, durability, and aesthetic appeal make it a preferred choice for windows, facades, mirrors, and more. The production of flat glass is a complex process involving several stages, each critical to ensuring the quality and functionality of the final product.

The Manufacturing Process

The production of flat glass primarily involves the float glass process, which was developed in the 1950s and has since become the industry standard. This process begins with raw materials, which typically include silica sand, sodium carbonate (soda ash), and limestone. These materials are combined and heated in a furnace at temperatures reaching up to 1700 degrees Celsius. The intense heat causes the raw materials to melt, forming a molten glass.

Once the glass is molten, it is carefully poured onto a surface of molten tin in a controlled environment. This technique allows the glass to spread out evenly, creating a smooth and flat surface. As the glass floats on the tin, it cools and solidifies into a sheet, typically measuring several meters in length. After cooling, the flat glass undergoes a series of cutting processes that allow it to be shaped into various sizes and thicknesses, depending on the specific application needed.

Quality Control

Quality control is a crucial aspect of flat glass production. Manufacturers implement stringent inspection processes throughout the production stages to ensure that the final product meets industry standards. This involves checking for visual defects, measuring thickness, and testing the glass's strength and thermal resistance. Advanced technologies, such as computer vision systems and laser measurement tools, are often employed to enhance the accuracy of quality checks.

Environmental considerations are increasingly influencing the production of flat glass. Manufacturers are now focusing on sustainable practices, such as recycling glass materials and minimizing waste during the production process. The use of energy-efficient furnaces and the implementation of emissions control technologies are also being adopted to reduce the environmental impact of glass manufacturing.

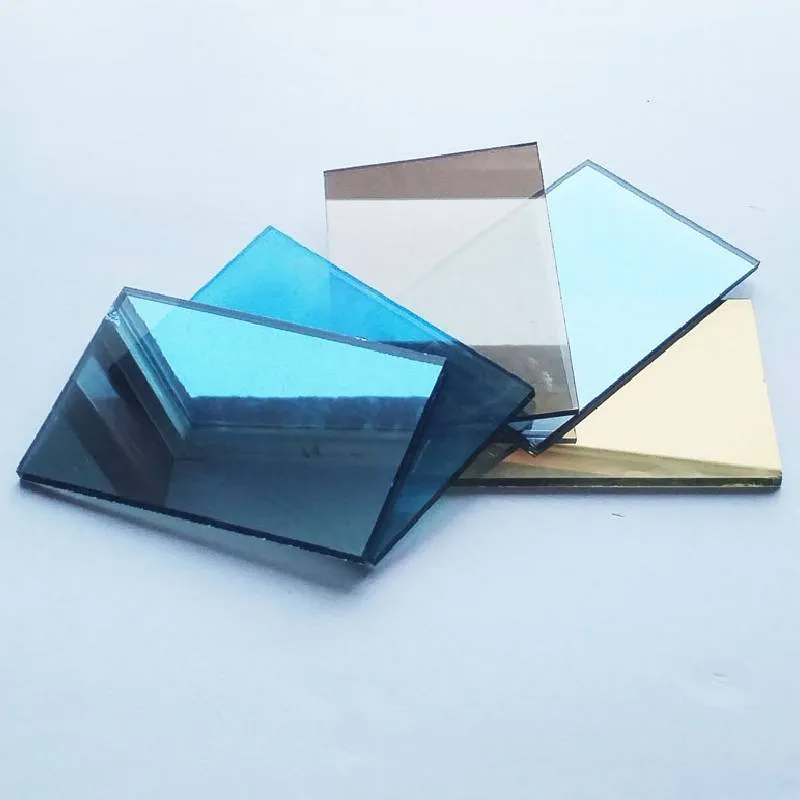

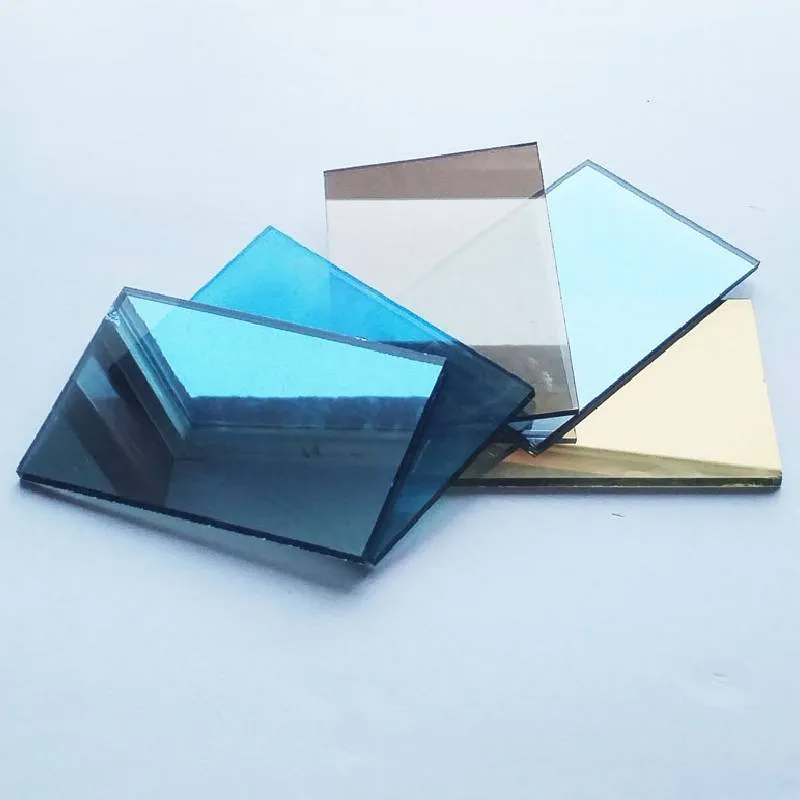

flat glass production

Applications of Flat Glass

The applications of flat glass are vast and varied. In the construction industry, flat glass is used for windows, doors, partitions, and facades, contributing significantly to the aesthetic and energy efficiency of buildings. Insulated glass units (IGUs) are commonly used to improve thermal performance and energy conservation in residential and commercial properties.

In the automotive sector, flat glass is employed for windshields, side windows, and rear windows. Manufacturers of vehicles often prioritize safety and durability, making laminated and tempered glass the preferred choices. These types of glass not only provide enhanced protection in case of accidents but also reduce noise and improve energy efficiency in vehicles.

The electronics industry has also found a burgeoning use for flat glass, particularly in the production of screens for televisions, computers, and mobile devices. Thin and lightweight glass solutions help enhance display performance while meeting the demands of modern technology.

The Future of Flat Glass Production

As technology evolves, so too does the flat glass industry. Innovations such as smart glass—a type of glass that can change its properties, such as tint and transparency, in response to environmental stimuli—are paving the way for smarter buildings and energy-efficient solutions. The integration of IoT (Internet of Things) technologies into flat glass applications is set to revolutionize how buildings interact with their environment.

In conclusion, flat glass production is a vital component of multiple industries, driven by ongoing technological advancements and a commitment to sustainability. As market demands continue to change, the flat glass industry will need to adapt, focusing on innovative solutions that enhance functionality while minimizing environmental impact. With its broad range of applications, flat glass will undoubtedly remain a cornerstone of modern architecture and design for years to come.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu