The Importance of Glass Tempering Furnace Manufacturers

In the ever-evolving world of glass manufacturing, the role of glass tempering furnace manufacturers is pivotal. With the increase in demand for high-quality tempered glass in various industries, these manufacturers play a crucial part in ensuring not only the quality but also the safety and efficiency of glass products. This article delves into what glass tempering furnaces are, their significance in the glass production process, and the attributes that set successful manufacturers apart.

Glass tempering is a process that involves heating glass to a high temperature and then cooling it rapidly. This technique increases the strength and durability of the glass, making it resistant to thermal shock, impacts, and breakage. Tempered glass is widely used in applications such as automotive windows, shower doors, glass doors, and facades, making the need for high-quality tempering furnaces essential.

Manufacturers of glass tempering furnaces must adhere to rigorous standards. The design and construction of these furnaces should ensure uniform heating and cooling, which is critical for producing consistently high-quality tempered glass. Advanced technological features such as precise temperature control systems, efficient gas or electric heating elements, and high-performance cooling systems are indispensable. The latest furnaces incorporate computer-controlled mechanisms that enhance efficiency, reduce energy consumption, and optimize production cycles, meeting the needs of modern glass manufacturers.

When evaluating glass tempering furnace manufacturers, several key factors come into play. Firstly, the experience and reputation of a manufacturer are paramount. Established manufacturers with a proven track record can assure buyers of the reliability and performance of their products. Customer reviews, case studies, and industry certifications can provide valuable insights into a manufacturer’s credibility.

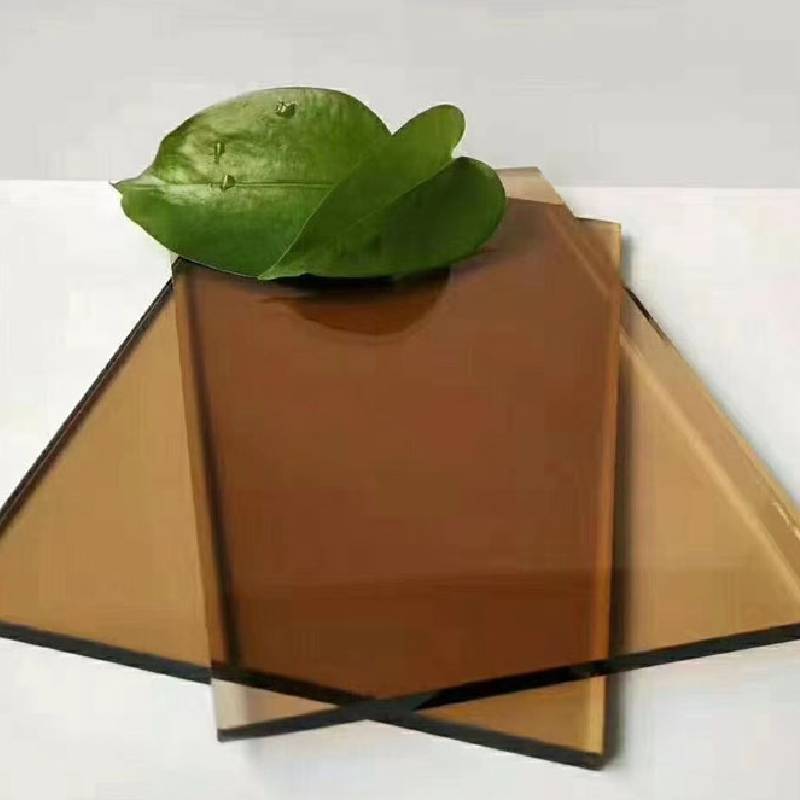

glass tempering furnace manufacturers

Moreover, the level of customization offered is a significant factor. Different glass products require specific tempering processes. A reliable manufacturer should provide tailored solutions that cater to the unique needs of various glass types and the specific requirements of their clients. This flexibility can greatly enhance production efficiency and product quality.

Another critical aspect is after-sales support. The glass tempering process can be complex, and having a manufacturer that provides ongoing technical support, maintenance services, and spare parts can be invaluable. This support ensures that the equipment operates smoothly over its lifespan, minimizing downtime and maximizing productivity.

Additionally, the integration of innovative technologies is a hallmark of leading glass tempering furnace manufacturers. The push towards automation, data analytics, and enhanced safety features is reshaping the industry. Manufacturers that invest in research and development and adapt to the latest trends in technology will stand out in a competitive market.

In conclusion, glass tempering furnace manufacturers are essential players in the glass production ecosystem. Their ability to produce high-quality, efficient, and safe tempering furnaces directly impacts the performance of tempered glass products. As industries continue to demand stronger and more reliable glass, the role of these manufacturers will only grow in importance. By focusing on innovation, customization, and robust support, they will help shape the future of glass manufacturing.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu