The Process of Making Toughened Glass

Toughened glass, also known as tempered glass, is a type of safety glass that has been heat-treated to enhance its strength and thermal resistance. This process not only improves its durability but also ensures safer fragmentation upon breakage. Understanding the process of making toughened glass involves exploring several stages that intricately combine physics, engineering, and chemistry.

Step 1 Selection of Raw Materials

The journey of toughened glass begins with the selection of raw materials. Standard glass is made from silica sand, soda ash, and limestone. The mixture is carefully proportioned, as the quality of the raw materials significantly influences the glass's final properties. High purity silica is essential, as impurities can lead to weaknesses in the glass structure. Other additives may be included to impart specific characteristics, such as reduced thermal expansion or improved clarity.

Step 2 Melting the Glass

Once the raw materials are prepared, they enter a furnace where they are heated to temperatures exceeding 1500 degrees Celsius (2732 degrees Fahrenheit). This process transforms the raw materials into molten glass. The melting phase is critical, as it must be maintained long enough to ensure that all particles are homogeneously mixed and any bubbles are eliminated. The quality of the molten glass will directly affect the final product.

Step 3 Forming the Glass

After melting, the molten glass is shaped into sheets through various forming techniques, with the most common method being floating. In this technique, the molten glass is poured onto a bed of molten tin, allowing it to spread evenly and create flat sheets. As the glass cools, it solidifies and maintains a uniform thickness with smooth surfaces. This stage is crucial, as any imperfections can compromise the integrity of the final toughened glass.

Step 4 Annealing

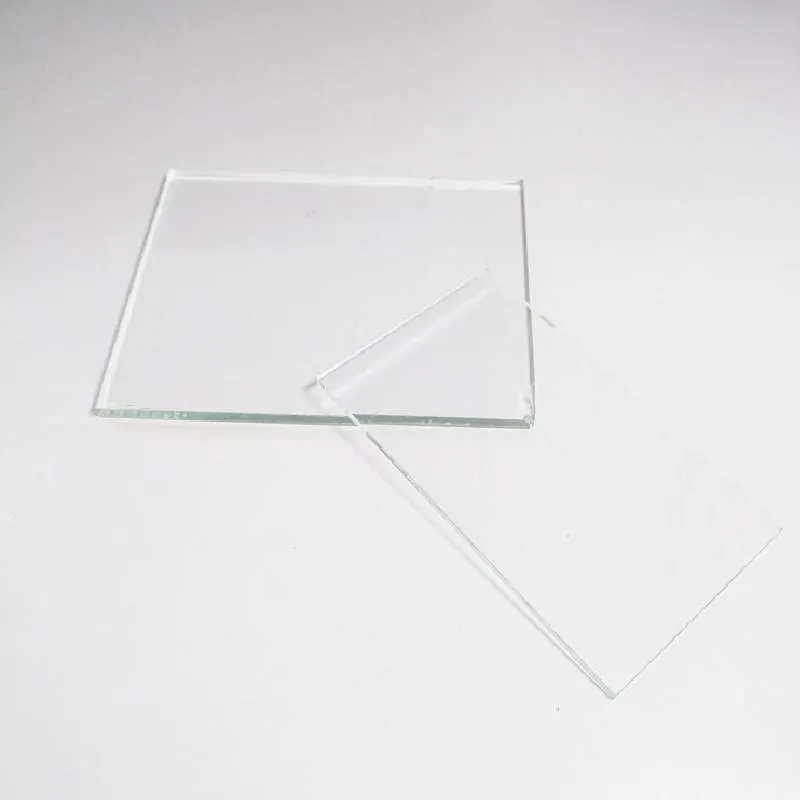

process of making toughened glass

Following formation, the glass sheets must undergo annealing, a controlled cooling process that reduces internal stresses. The glass is placed in an annealing lehr where the temperature is gradually lowered. If cooling occurs too rapidly, it could lead to stress fractures, which would undermine the glass's strength. By regulating the temperature, the manufacturing process ensures that the glass remains stable and free from spontaneous breakage.

Step 5 Toughening Process

The toughening process itself involves heating the annealed glass to approximately 620 degrees Celsius (1148 degrees Fahrenheit) and then rapidly cooling it using jets of cold air. This heating and cooling method introduces compressive stresses on the surface of the glass while creating tensile stresses within it. As a result, the outer surfaces become significantly stronger than the inner portions. Toughened glass can withstand impacts, thermal shocks, and sudden temperature changes that standard glass cannot endure.

Step 6 Cutting and Finishing

After toughening, the glass sheets are inspected for quality and may then be cut into specific dimensions according to customer requirements. Unlike ordinary glass, toughened glass cannot be cut after the toughening process; therefore, precise measurements are vital. Edges may be polished or treated to prevent chipping, ensuring the glass meets aesthetic and safety standards.

Step 7 Quality Control

Before reaching the market, toughened glass undergoes rigorous quality control checks. This includes evaluating distortions, bubbles, and scratches, as well as testing the strength and thermal resistance of the product. Regulatory standards dictate that toughened glass must meet specific safety requirements, particularly when used in construction, automotive, or appliance industries.

Conclusion

In summary, the process of making toughened glass is a complex interplay of science and industry. From selecting the right raw materials to adhering to stringent quality control measures, each step lays the groundwork for a product renowned for its strength and safety. As technology continues to evolve, so too does the manufacturing of toughened glass, which plays a pivotal role in modern architecture and design, ensuring that safety and aesthetics go hand in hand.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu