The Process of Toughened Glass Making

Toughened glass, also known as tempered glass, is a type of safety glass that is treated to be much stronger than normal glass. This process of toughening glass not only enhances its strength and safety but also allows it to be used in a variety of applications, from skyscrapers to shower doors. The production of toughened glass involves several precise steps, requiring careful control of temperature and timing to achieve the desired properties.

1. The Raw Materials

The process of making toughened glass begins with the selection of raw materials. Typically, soda-lime glass is used due to its favorable properties and cost-effectiveness. The raw materials for soda-lime glass include silica sand, soda ash, and limestone. These ingredients are melted together in a furnace at temperatures exceeding 1600 degrees Celsius. This high-temperature environment turns the raw materials into a molten glass that can be formed into sheets.

2. Forming the Glass

Once the glass is molten, it is formed into sheets using various methods such as the float process or rolling. In the float process, molten glass is poured onto a bath of molten tin, causing it to spread out and flatten into a smooth sheet. This method results in glass that is uniform in thickness and transparency, which is crucial for further processing. After forming, the sheets are cooled to a temperature at which they can be safely handled.

3. Cutting and Edge Work

After the glass sheets have cooled, they are cut to the required dimensions. At this stage, edge work is often performed to smooth and polish the edges. Proper edge treatment is essential as it minimizes the risks of chipping or breaking during the subsequent toughening process. Edge work may involve grinding and polishing to achieve a refined finish that ensures both aesthetics and safety.

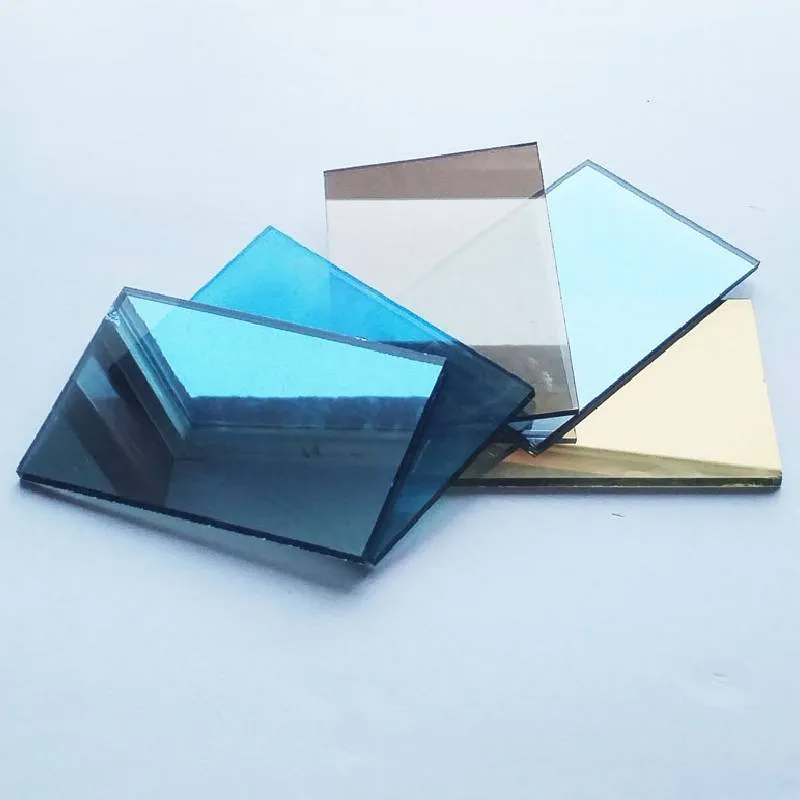

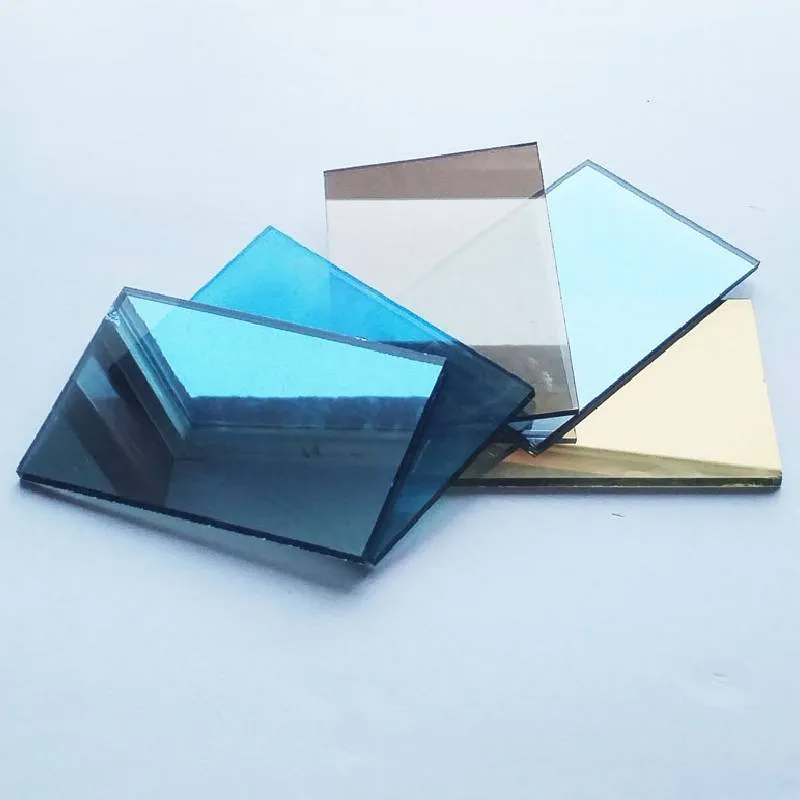

toughened glass making

4. The Toughening Process

The real magic happens during the toughening process, where the glass undergoes thermal treatment. The glass sheets are heated in a furnace to approximately 620 degrees Celsius. This heating process makes the glass soft and pliable. The sheets are then rapidly cooled using jets of cold air, a process known as quenching. This rapid cooling creates a compressive stress on the surface of the glass while keeping its internal structure under tension.

The result of this thermal treatment is a glass that is significantly stronger than untreated glass. In fact, toughened glass can withstand impacts and thermal stresses that would cause normal glass to shatter. This strength makes it ideal for use in high-stress environments, such as windows in high-rise buildings, glass doors, and even in automotive applications.

5. Applications of Toughened Glass

The applications of toughened glass are vast and varied. Its strength and safety characteristics make it suitable for architectural elements, including facades and partitions in commercial buildings. In residential settings, toughened glass is often used for shower enclosures, glass tabletops, and balustrades. Additionally, toughened glass is extensively used in the automotive industry, where it is employed in side and rear windows for its shatter-resistant qualities.

Another significant application is in the electronics industry; toughened glass is used in screens for smartphones and tablets, where durability is essential. The ability of toughened glass to withstand thermal changes also makes it suitable for contexts like oven doors and cooktops.

Conclusion

Toughened glass is a remarkable material, thanks to its durable and safety-oriented properties. The process of creating toughened glass is a blend of art and science, combining advanced techniques with precision engineering. As technology continues to advance, the methods for producing tougher, lighter, and more aesthetically pleasing glass will likely evolve, further broadening the possibilities for this versatile material. Whether in architecture, transport, or electronics, toughened glass is poised to remain a key player in modern design and safety solutions.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu