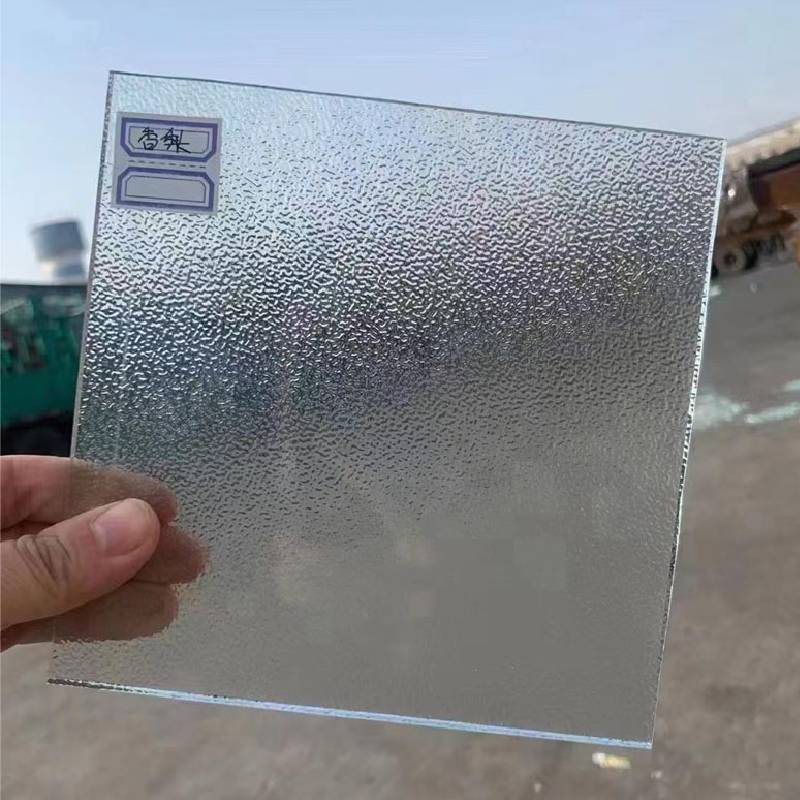

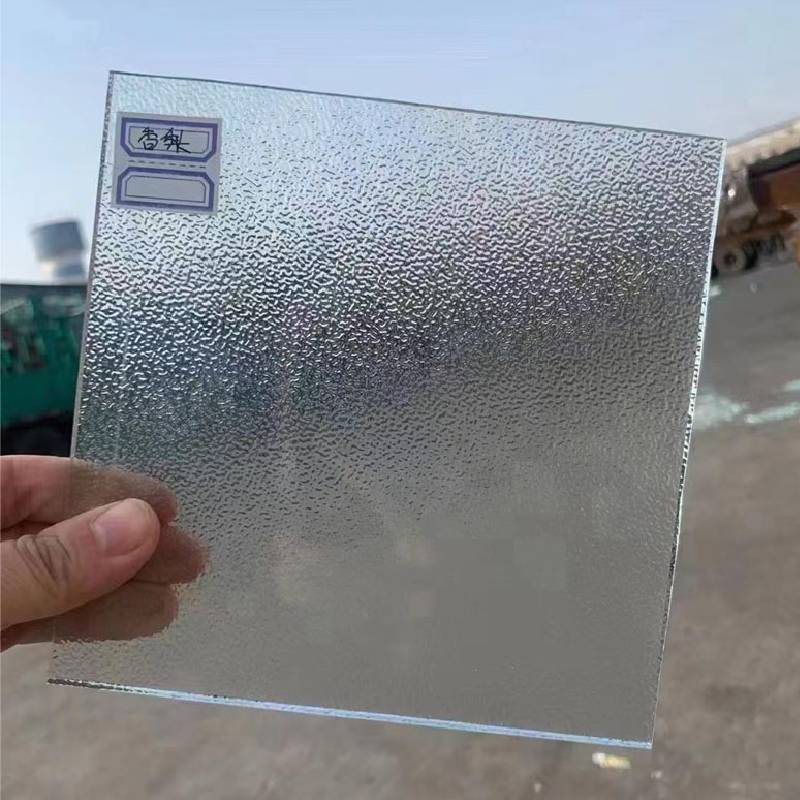

Typical Nashiji Obscure Pattern Glass texture (3mm/4mm)

1. Industry Overview: The Rise of 3mm 4mm Nashiji obscure pattern glass

In the era of modern architecture and advanced industrial processing, the demand for obscured yet light-permeable glass solutions has significantly increased. Among these,

the 3mm 4mm Nashiji obscure pattern glass stands out due to its excellent balance of privacy,

aesthetics, and durability. According to the MarketsandMarkets Glass Report 2023, the global patterned and obscure glass market

is projected to reach USD 8.2 billion by 2027, with Nashiji-patterned glass forming a major share due to its utility in commercial, residential, and industrial sectors.

- Applications: Office partitions, shower rooms, facades, sanitary ware, laboratory windows.

- Growth Drivers: Trend towards decorative yet functional design; increased privacy regulations in commercial architecture.

- Regional Demand: Especially rising in Asia-Pacific due to rapid urbanization; Europe favors it for eco-construction projects.

Application example in industrial settings (Nashiji Obscure Pattern Glass 4mm)

2. Technical Specifications of 3mm 4mm Nashiji obscure pattern glass

Product Technical Parameters Overview

| Item |

3mm Nashiji |

4mm Nashiji |

Standard |

Light Transmission |

Surface Pattern |

Max Size |

Color Options |

| Thickness |

3mm ±0.2mm |

4mm ±0.2mm |

ISO 12543 / ANSI Z97.1 / EN 572-5 |

78%~85% |

Nashiji (Obscure/Wavy/Sandblasted Feel) |

1830×2440mm |

Clear, Bronze, Grey, Blue, Green |

| Density |

2.47 g/cm³ |

2.47 g/cm³ |

74%~82% |

2140×3300mm |

| UV Resistance |

>99% |

GB/T 17841-2019 |

High (Tested up to 1200h exposure) |

| Acid / Alkali Resistance |

Level A |

ISO 695 |

Excellent chemical resistance |

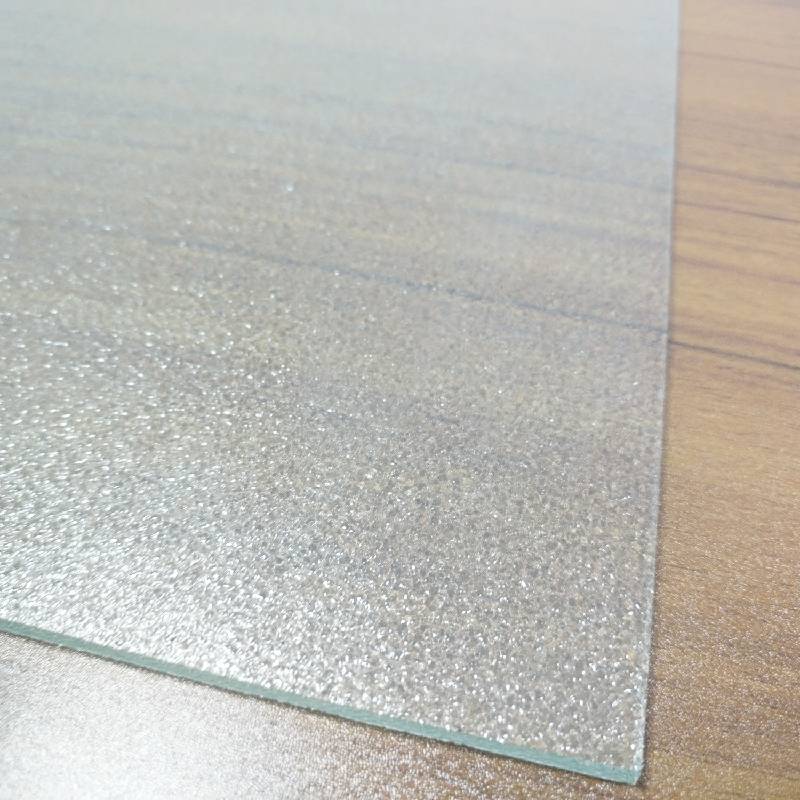

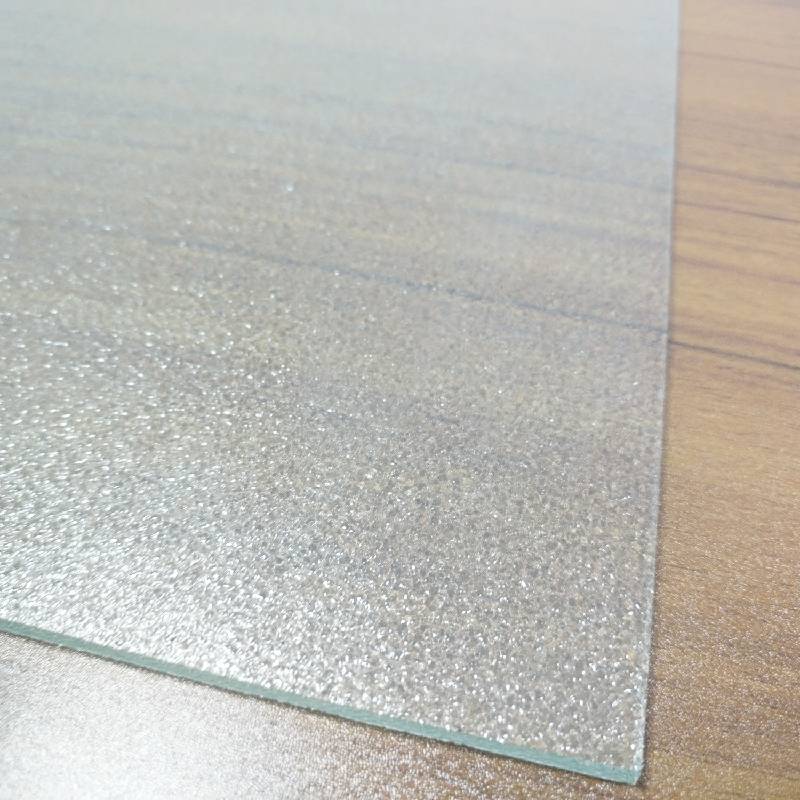

Light Transmission & Mechanical Strength Comparison (3mm vs 4mm)

Nashiji Obscure Pattern Glass in architectural design

3. Manufacturing Process of 3mm 4mm Nashiji obscure pattern glass

Nashiji Obscure Pattern Glass Manufacturing Flow

Raw Silica Sand + Flux

→

Batch Melting

(>1600℃, soda-lime-silicate formation)

→

Pattern Rolling

(Casting on Nashiji Rollers)

→

Annealing

(Stress relief in lehr)

→

Cut-to-Size / Edgework

→

Inspection & Testing

(ISO/ANSI standard)

→

Packing & Logistics

Each stage is monitored by automated sensors for thickness, pattern depth, and surface defects.

Testing covers glass optical, mechanical, and chemical stability in accordance with ISO 12543, ANSI Z97.1, and EN 572-5.

Key Features from a Technical Perspective

- Material: High-purity soda-lime glass, with patterned surface etched via precision rolling for Nashiji obscure effect.

- Pattern Consistency: Modern CNC-controlled rollers ensure raw Nashiji texture depth between 0.18-0.35mm, securing consistent diffusion of light and privacy.

- Quality Control: Laser and camera inspection for surface wave, thickness, bubble, and pattern distribution.

- Certification: Regular audits to ISO 12543, ANSI Z97.1, EN 572-5.

- Resistance: Nashiji glass achieves superior weathering resistance, with testing showing color and structure stability after 1,500h accelerated weather exposure.

- Service Life: 15~30 years in typical outdoor/indoor architectural use, as verified by third party SGS testing.

Expert installation and edge processing for Nashiji patterned glass

4. Benchmarking: Nashiji Glass vs. Standard Patterned Glass

Performance Comparison Table

|

3mm Nashiji |

4mm Nashiji |

Common Patterned Glass (3mm/4mm) |

| Pattern Uniformity |

High (0.18mm depth) |

High (0.35mm depth) |

Moderate (0.12~0.24mm) |

| Privacy Rating |

Level 3 (High diffused) |

Level 3 |

Level 1~2 |

| Light Transmission |

84% |

78% |

80% (avg.) |

| Thermal Expansion |

9.0×10-6/K |

9.0×10-6/K |

9.1×10-6/K |

| Acid/Chemical Resistance |

Excellent (ISO 695 Class A) |

Excellent |

Good |

| Service Life |

≥ 28 years |

≥ 30 years |

~20 years |

Share of 3mm 4mm Nashiji obscure pattern glass Usage by Industry (2023*)

5. Custom Solutions & Typical Application Scenarios

Customization is a core competence of modern manufacturers for 3mm 4mm Nashiji obscure pattern glass.

Solutions can be tailored in terms of dimension (cut-to-size, oversized), pattern density, tint, colored films, and even in-laminate assembly for safety.

Edgework (arrissed, polished, beveled) and toughening/lamination options further empower project requirements.

-

Project Type: Residential (windows, bathroom partitions, glass doors), Commercial Buildings (offices, hotels, malls), Industrial Glazing (factory partitions, laboratory view panels), Water Treatment Facilities (chemical-resistant panels).

-

Case Example 1: Shanghai Pudong Hospital (2023) used 5,200m² of 4mm Nashiji obscure glass in lab partitions, ensuring high light throughput and chemical resistance.

-

Case Example 2: Zhejiang Petrochemical Plant (2022) - 3mm Nashiji employed for control room windowing, offering privacy + 25% less UV transmittance vs. standard patterned glass.

-

Feedback Snapshot:

‘Excellent service life, easy to clean, and fulfills our green building rating.’

– Ark Design Studio, 2024 Client Survey

-

Sustainability: Multiple LEED and BREEAM projects have cited Nashiji pattern glass for its daylighting and eco-friendly characteristics.

Application case: Nashiji patterned glass in water engineering

Durability Testing: Weather Resistance (Accelerated Hours Until Surface Degradation)

6. Industry Certifications, Partners, and Service Commitment

-

Industry Certifications: 3mm 4mm Nashiji obscure pattern glass is certified to ISO 12543 (safety glass in building),

EN 572-5 (patterned glass), and ANSI Z97.1 (US safety glass).

-

Cooperation Brands: Partners include Saint-Gobain, AGC Glass,

CSG Holding, and several leading construction groups in Asia, Europe.

-

Years in Service: Many suppliers, including SHZRGLASS, have >20 years experience in industrial and architectural glass production.

-

Warranties: Standard 10-year product warranty with optional 3-year on-site technical support.

-

Testing Reports: Certified by SGS, TÜV,

full compliance to ISO and ANSI/ASTM requirements.

-

After-sales: 24/7 multilingual support, fast delivery cycles (7-14 working days for standard orders).

7. FAQs on 3mm 4mm Nashiji obscure pattern glass – Expert Answers

- 1. What material is used for 3mm 4mm Nashiji obscure pattern glass?

- High purity soda-lime glass forms the base, ensuring optical clarity and mechanical strength. The Nashiji pattern is imparted during hot rolling using precision steel pattern rollers.

- 2. What are the standard thicknesses and size ranges available?

- 3mm and 4mm are the standard thicknesses, available in sheet sizes up to 2140×3300mm. Custom size cutting is possible while maintaining pattern integrity.

- 3. Are there international standards governing Nashiji pattern glass?

- Yes. Products comply with ISO 12543, EN 572-5, and ANSI Z97.1 for pattern uniformity, impact/safety, and optical properties.

- 4. What is the achievable light transmission and privacy level for Nashiji obscure pattern glass?

- Light transmission ranges from 78% (4mm) to 85% (3mm), with privacy levels 'High' (Level 3 diffusion), making it ideal for offices, bathrooms, and laboratory partitions.

- 5. How is the Nashiji pattern formed and tested?

- The Nashiji pattern is rolled on using CNC-engraved steel rollers at high temperature; pattern depth is measured via laser sensors, and surface uniformity is assessed under EN 572-5 / ISO 12543 protocols.

- 6. What edgework and finishing options are available?

- Arrissed, C-edge, polished, and beveled edge treatments are available. Tempering/laminating can be applied for enhanced safety or impact resistance.

- 7. What installation and cleaning standards should be followed?

- Follow ASTM C1048 or EN 1096 installation guidelines: use suitable gaskets, avoid cement/mortar contact, and clean with non-abrasive solvents only.

8. Delivery Cycle, Quality Assurance & Technical Services

-

Production Lead Time: For standard 3mm 4mm Nashiji obscure pattern glass, typical production+shipping is 7~14 working days. Custom color and jumbo-size variants may require 18~25 days.

-

Packing: Export-grade plywood crates with humidity protection and anti-abrasion layers.

-

Quality Guarantee: >99.7% pass rate, traceable batch certification with every delivery.

-

On-site Technical Support: For project clients, complete support from engineering team is available (design-fit, on-site measuring, post-install check).

-

Maintenance Guide: Detailed care/instruction manuals provided; compliance with RoHS for environmental safety.

References and Further Reading:

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu