Exploring the World of Float Glass Manufacturing

Float glass, a term that has gained prominence in both architectural and industrial applications, has revolutionized the way we think about glass production. This process, known for its efficiency and versatility, was first developed in the 1950s and has since become the dominant method for producing clear glass sheets. As we delve into the world of float glass manufacturing, we uncover the key processes, benefits, and the future of the industry.

The Float Glass Process

The float glass manufacturing process begins with high-quality raw materials, primarily silica sand, soda ash, and limestone. These materials are carefully measured and mixed to create a batch. Additionally, various additives such as cullet (recycled glass) are incorporated into the mix to enhance the properties of the final product.

Once the ingredients are prepared, they are melted in a furnace at temperatures reaching up to 1,700 degrees Celsius (3,100 degrees Fahrenheit). This molten glass is then poured onto a bath of molten tin, which has a lower density. The glass spreads out on the surface of the tin, forming a flat, uniform layer. This is the essence of the “float” in float glass—the glass floats on the tin.

After the glass has formed, it is gradually cooled down in a process called annealing, which relieves internal stresses within the material. This cooling stage is essential for producing high-quality glass that can withstand various applications. Finally, the glass is cut into sheets of desired sizes and packaged for distribution.

Advantages of Float Glass

Float glass offers several significant advantages that make it the preferred choice for manufacturers and consumers alike. Firstly, it provides excellent optical clarity. The smooth surface achieved through the float process minimizes distortions, making it ideal for applications where transparency and visibility are crucial, such as windows and displays.

Secondly, float glass can be produced in large sizes, providing versatility for various construction and design needs. It can easily be customized into different thicknesses and treatments, such as laminated or tempered glass, to enhance strength and safety.

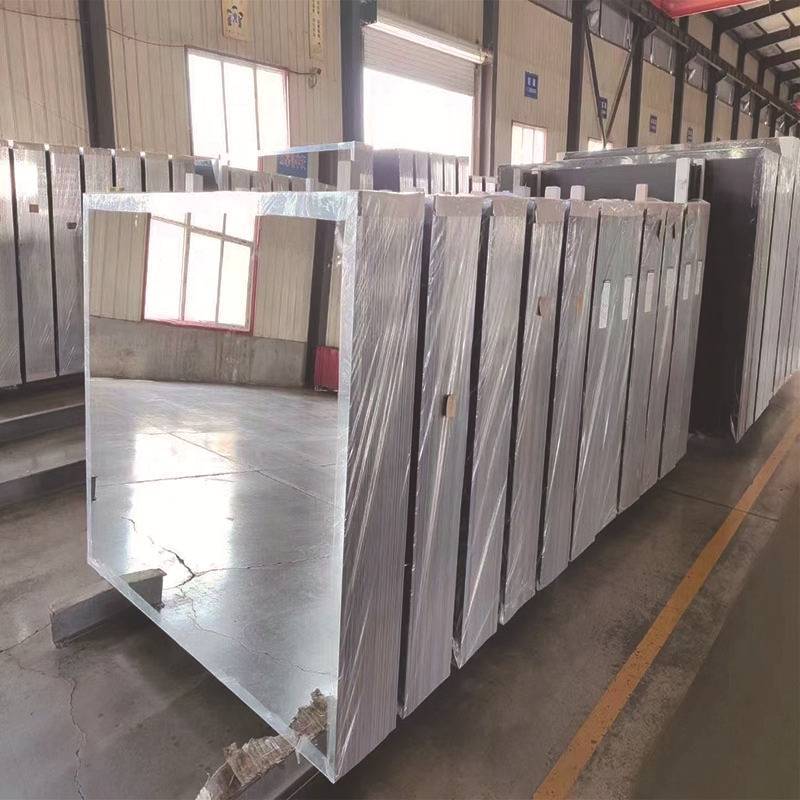

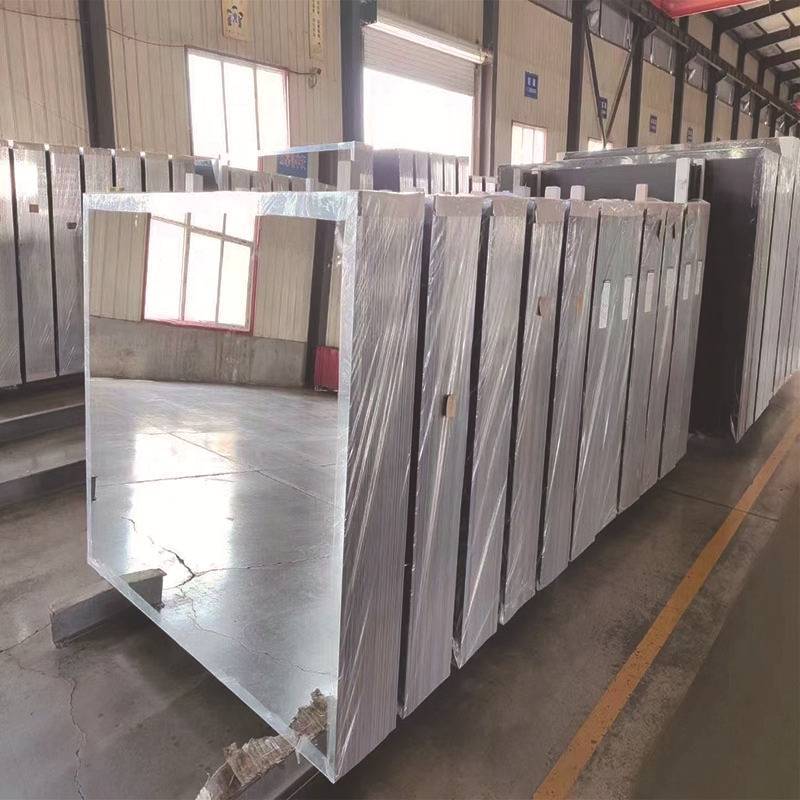

float glass manufacturer

Furthermore, float glass is environmentally friendly

. The recycling process of cullet not only reduces the need for raw materials but also lowers energy consumption during production, resulting in a smaller carbon footprint.

Applications of Float Glass

The applications of float glass are extensive and varied. In the architectural realm, it is commonly used for windows, facades, and curtain walls, blending aesthetics with functionality. In the automotive industry, float glass is pivotal for windshield and window manufacturing, where strength and clarity are paramount.

Moreover, float glass finds its way into the production of glass furniture, mirrors, and a wide array of decorative items. Its adaptability means that it can be transformed through various processing techniques like cutting, polishing, and coating to meet specific customer demands.

The Future of Float Glass Manufacturing

As we move toward a more sustainable future, the float glass industry is adapting to new challenges and opportunities. Innovations in manufacturing processes are essential for reducing waste and enhancing energy efficiency. Technologies such as smart glass, which can change transparency based on external conditions, are also on the rise, providing exciting prospects for architects and interior designers.

Furthermore, the increasing focus on eco-friendly materials and practices is shaping the future of float glass manufacturing. Manufacturers are continuously investing in research and development to produce more sustainable glass solutions, thus aligning with global environmental goals.

Conclusion

Float glass manufacturing represents a convergence of tradition and innovation. Its ability to produce high-quality, clear glass efficiently has made it an integral part of modern construction and design. With ongoing advancements and a commitment to sustainability, the future of float glass looks bright—ushering in new possibilities for industries around the globe. Through continued investment in technology and sustainable practices, float glass manufacturers will undoubtedly play a crucial role in shaping our built environment.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu