The float glass process, a revolutionary method in the glass manufacturing industry, has shaped the way transparent surfaces are produced globally. Understanding this process offers a glimpse into the sophistication of modern manufacturing and the demanding standards it upholds in delivering premium quality glass.

At its core, the float glass process ensures the creation of uniform and high-quality glass sheets by floating molten glass on a bed of molten tin. This remarkable technique, devised in the 1950s, has since become the gold standard. As a professional deeply entrenched in the glass production landscape, I've witnessed the myriad benefits and challenges inherent in this process firsthand.

The key advantage of the float glass process is its unparalleled ability to produce glass with a perfectly smooth surface. This outcome is achieved thanks to the precise control over the molten glass's spread across the tin bed—a critical factor for applications demanding optical clarity, such as in construction and automotive industries. The meticulous control over temperature and constituents ensures the glass is not only stunningly flat but also free from imperfections, making it ideal for energy-efficient windows, facades, and even smartphone screens.

Yet, achieving such perfection is not without its challenges. The process requires a keen understanding of material science and thermal dynamics. Slight variances in the raw materials or the temperature gradients can lead to suboptimal results.

This is where expertise in the field becomes indispensable. Professionals must constantly monitor the composition of silica, soda ash, and lime—the trifecta of glass-making ingredients—to ensure consistent quality. Over time, I've learned that the subtleties of this composition allow room for innovation, leading to products that can cater to evolving industry standards, such as increased durability and enhanced thermal insulation.

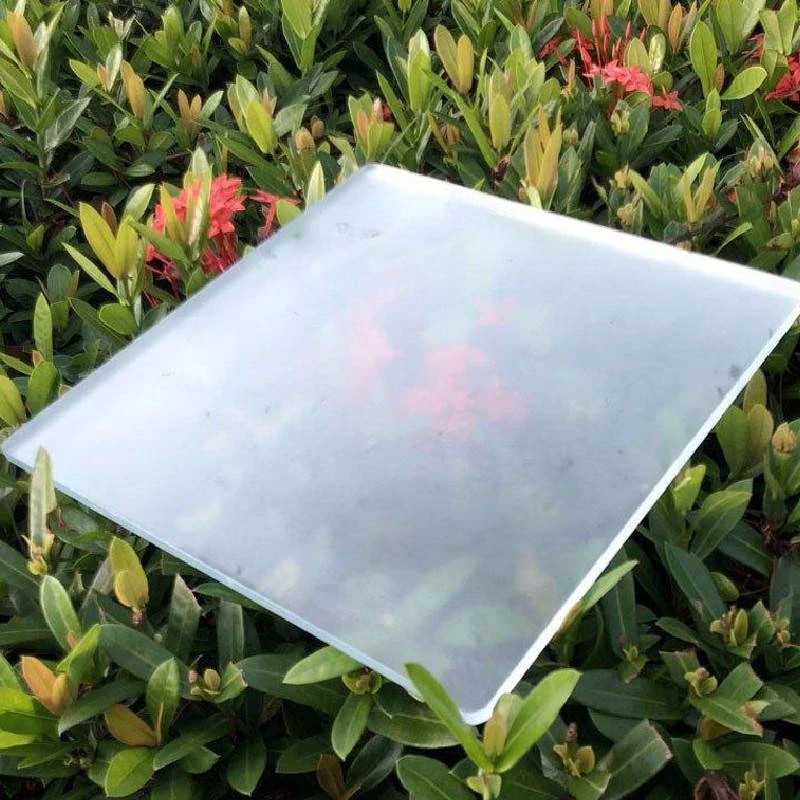

float glass process

From an authoritative perspective, the float glass process stands as a testament to the advances in materials engineering. The process not only highlights our ability to control complex chemical reactions but also emphasizes sustainable practices. Modern production facilities are increasingly integrating eco-friendly methods to recycle the significant amounts of water and other natural resources consumed during production. As an industry expert, it's crucial to advocate for these practices and educate stakeholders about the environmental responsibilities all players must bear.

Trust in the float glass process is also bolstered by its track record for safety and reliability. The rigorous quality control mechanisms in place, from initial raw material selection to the final annealing process, establish a strong basis of trust with clients. By adhering to stringent international standards, manufacturers can assure end-users of the product's performance, be it in skyscraper windows enduring harsh weather conditions or the precision-cut panels in modern electronic devices.

In sum, the float glass process not only revolutionizes the production of flat glass but also embodies the pinnacle of modern manufacturing techniques. Its ability to blend tradition with innovation while maintaining sustainability and safety offers a model for other industrial processes. As we progress further into an era of technological advancements, this process will undoubtedly continue to evolve, promising even more exciting developments for glass applications in diverse fields.

This deep dive into the inner workings and implications of the float glass process underscores the importance of maintaining a balance between expert control and innovative flexibility—qualities that will ensure its relevance in the future global market.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu