Toughened glass, commonly known as tempered glass, plays an integral role in both industrial and consumer applications due to its enhanced safety and durability features. Crafting this specialized glass involves a meticulous manufacturing process blending sophisticated technology with precise engineering to achieve a product esteemed for its strength and reliability.

The journey of toughened glass begins with selecting high-quality raw materials, primarily silica sand, soda ash, and limestone. These components are meticulously measured and combined to form glass that meets high standards for clarity and consistency. The mixture is then melted at approximately 1700 degrees Celsius, forming a molten glass that can be molded into the desired shape.

Once the raw glass is shaped, the crucial stage of thermal tempering begins. This process involves heating the glass in a specialized tempering furnace to temperatures nearing 600 to 700 degrees Celsius. This stage is pivotal as it influences the glass’s ultimate strength and safety features. Maintaining a consistent temperature throughout the panel is essential to ensure uniform properties across the entire surface.

Upon reaching the optimal temperature, the glass undergoes rapid cooling, known as quenching. This phase involves blasting the hot glass surface with high-pressure cool air, causing the exterior to cool much faster than the interior. This rapid cooling creates compressive stresses on the outer surfaces and tensile stresses inside the glass. These induced stress layers are responsible for the enhanced strength and breakage pattern of toughened glass. In comparison to standard glass, tempering increases the strength of the glass significantly, allowing it to withstand higher physical impacts.

A distinctive safety feature of toughened glass is its breakage pattern. Unlike ordinary glass that shatters into jagged shards, tempered glass breaks into small, blunt fragments, significantly reducing the risk of injury. This property makes it an excellent choice for applications where safety is a paramount concern, such as automotive windows, shower doors, and architectural glazing.

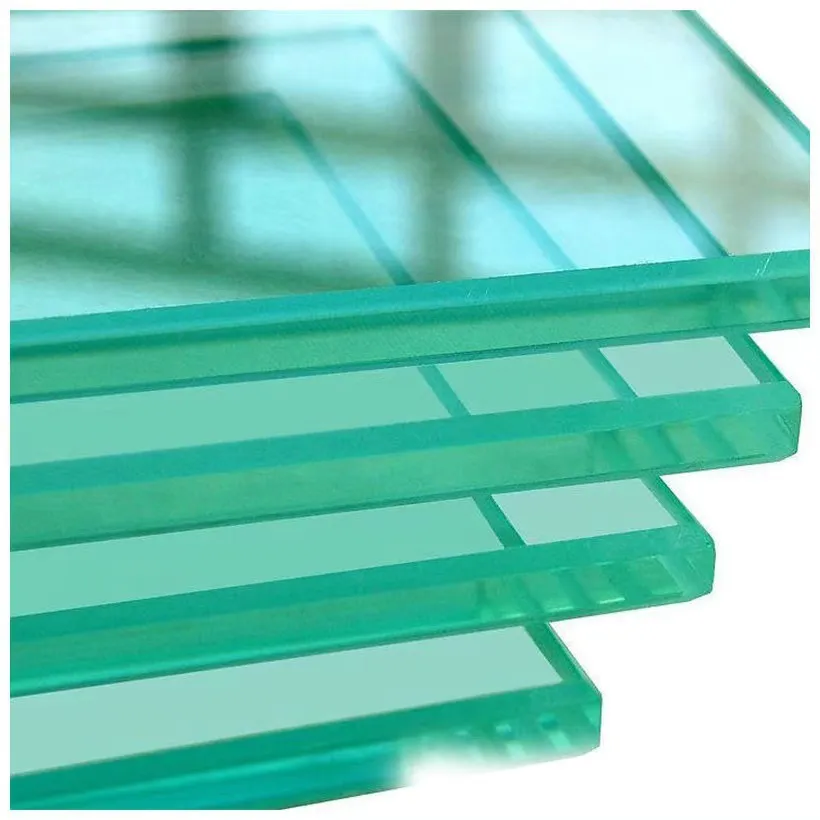

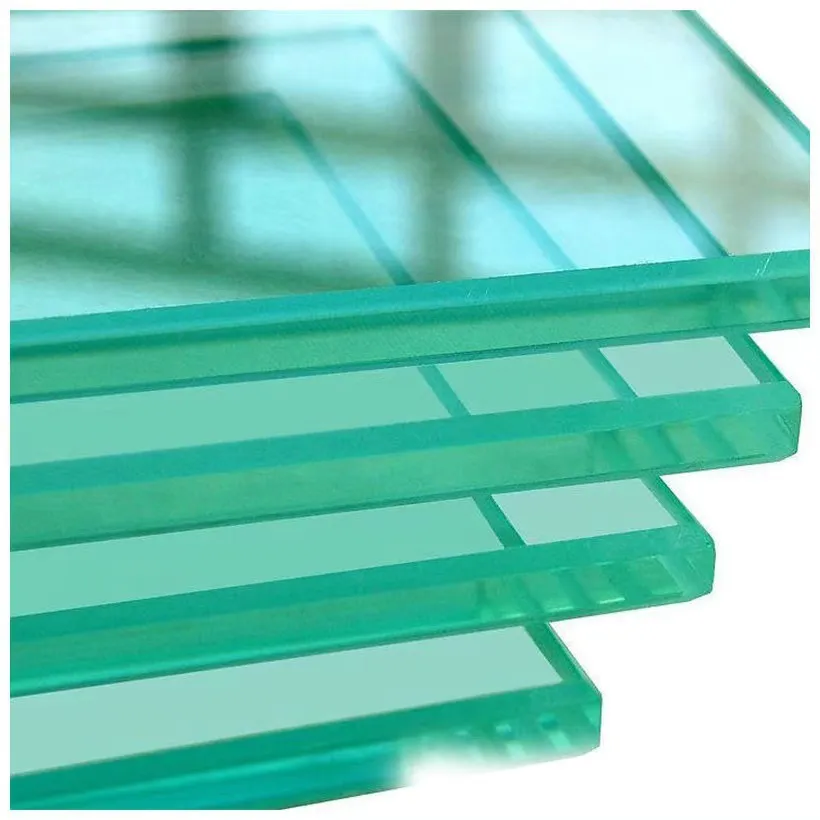

manufacturing process of toughened glass

Quality control is a critical component throughout the manufacturing process. Each panel of toughened glass undergoes rigorous inspections to ensure it meets international safety and quality standards, such as ANSI Z97.1 and EN 12150. Parameters such as surface compression, edge strength, and optical distortion are carefully measured. Meeting these standards is not merely a regulatory obligation but a testament to the manufacturer's commitment to quality and safety.

Innovations in toughened glass manufacturing continue to evolve, driven by the increasing demand for more resilient and environmentally friendly products. The advent of new technologies such as chemical tempering and advanced coatings has expanded the capabilities of toughened glass. Chemical tempering offers an alternative by using a controlled ion exchange process, which can increase the surface strength even more without affecting the visual clarity. Additionally, advanced coatings enhance energy efficiency, reduce glare, and provide additional layers of protection against scratches and environmental damage.

Beyond technological advancements, the environmental impacts of glass manufacturing are garnering attention. Glass manufacturers are increasingly adopting sustainable practices, such as recycling waste glass, optimizing energy consumption, and reducing emissions, to minimize their ecological footprint. This not only contributes to environmental conservation but also appeals to an eco-conscious market.

Toughened glass exemplifies the blend of tradition and innovation, underpinned by scientific principles and enhanced through cutting-edge research. For consumers and industries seeking reliable and safe glass products, toughened glass provides peace of mind with its proven performance record. As the manufacturing processes continue to advance, the potential applications of toughened glass will likely expand, addressing new challenges and meeting the evolving demands of modern architecture and technology. By maintaining a focus on quality, safety, and environmental stewardship, the industry positions itself as a pivotal player in a sustainable future.

In conclusion, the manufacturing process of toughened glass is a testament to technological evolution and manufacturing precision. Its applications are broad and varied, offering aesthetic flexibility and unmatched safety features. The relentless pursuit of innovation within this sector ensures that toughened glass remains synonymous with quality and reliability, underpinning its vital role in contemporary application landscapes.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu