The process of making tempered glass is a fascinating journey involving high temperatures and rapid cooling that enhances the glass's strength and thermal resistance. Tempered glass, often used in buildings, vehicles, and various applications, is typically produced from standard glass, which undergoes significant transformation to achieve its robust properties.

The manufacturing process begins with the selection of high-quality raw materials, primarily silica sand, soda ash, and limestone. These materials are carefully mixed and heated in a furnace at temperatures exceeding 1,700 degrees Fahrenheit (about 925 degrees Celsius). This high-temperature environment melts the materials, creating a homogeneous molten glass.

Once the glass reaches the desired viscosity, it is shaped into sheets using various techniques, such as floating, rolling, or blowing. The float glass process is the most common method; it involves pouring molten glass onto a bed of molten tin, allowing it to spread and create a smooth, flat surface. After cooling slightly, the sheets are then cut into specific dimensions.

The next crucial step is the tempering process, which is what differentiates tempered glass from regular glass. The cut sheets are loaded into a tempering furnace, where they are reheated to temperatures between 1,200 to 1,400 degrees Fahrenheit (about 650 to 750 degrees Celsius). This heating phase is critical as it prepares the glass for the subsequent rapid cooling.

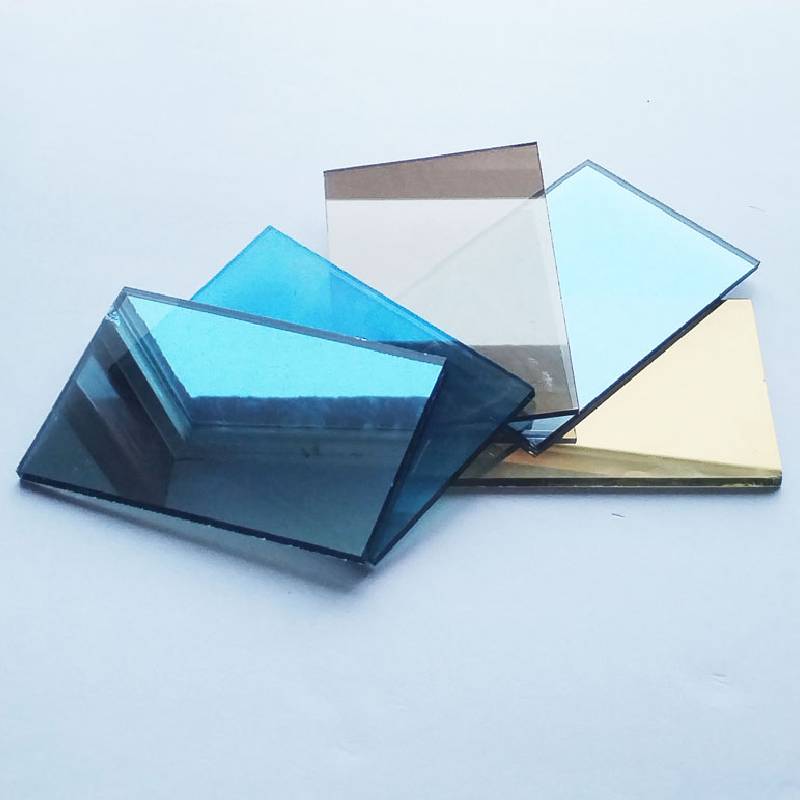

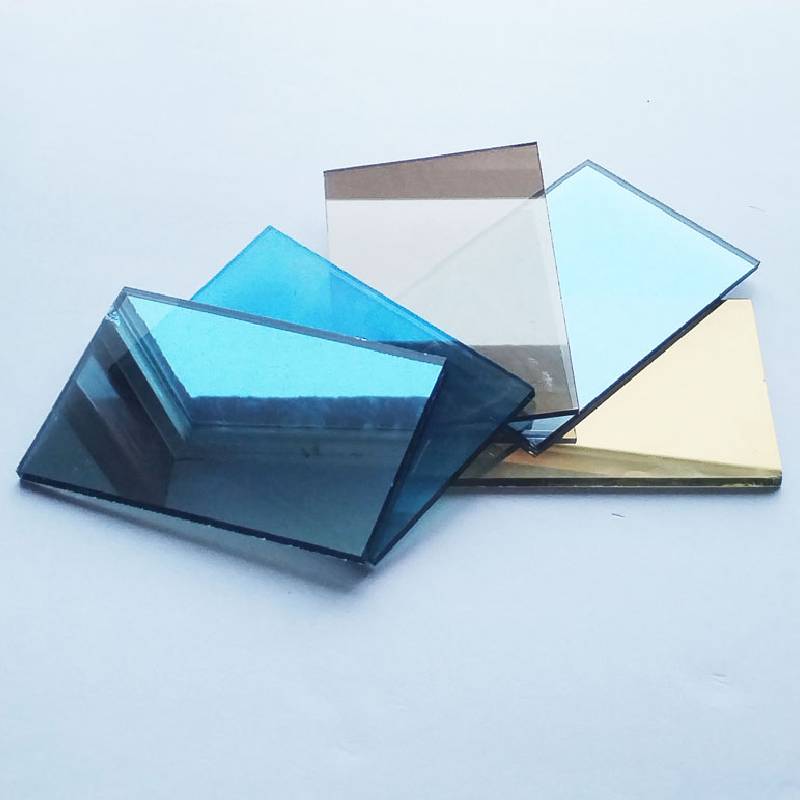

process of making tempered glass

Once heated, the glass is swiftly cooled in a controlled manner using high-velocity air jets. This quenching process solidifies the surface of the glass while the interior remains hot, creating a state of compression on the outer surfaces. This differential cooling causes the glass to increase in strength, making it five to six times stronger than untreated glass. Additionally, tempered glass is designed to shatter into small, blunt pieces when broken, minimizing the risk of injury compared to regular glass, which can shatter into sharp shards.

After the tempering process, the glass is inspected for quality, ensuring there are no defects that could compromise its strength or clarity. This quality control is vital for meeting safety standards and customer expectations.

Tempered glass is widely used in various applications, including shower doors, glass doors, storefronts, and car windows, due to its impressive durability. The combination of high strength, thermal resistance, and safety makes tempered glass a preferred choice in modern construction and design.

In conclusion, the process of making tempered glass is a meticulous and technologically advanced procedure that transforms ordinary glass into a material of remarkable strength and safety, essential for contemporary architectural and industrial applications.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu