- Market Analysis: Toughened Glass Pricing Variables

- Performance Advantages Over Conventional Glass

- Manufacturer Comparison Charts

- Budget Scenarios for Custom Requirements

- Architectural Application Case Studies

- Technical Constraints During Modification

- Cost-Efficiency Strategies for Large Projects

(toughened safety glass price)

Understanding Toughened Safety Glass Price Fluctuations

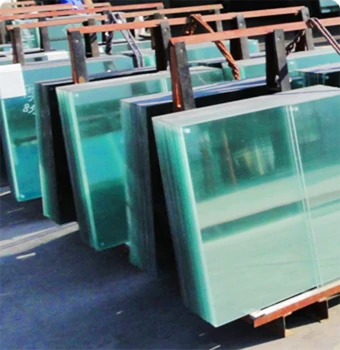

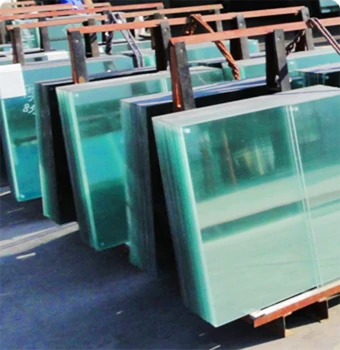

Market prices for toughened safety glass range dramatically from $25-$150 per square meter, influenced by critical variables. Geographic manufacturing costs account for 20-30% price differences, with Chinese factories typically offering 15% lower rates than European counterparts. Raw material expenses, particularly soda-lime silica composition quality, create 12-18% cost variations. Major price determinants include:

- Thickness specifications - Each millimeter increase adds 7-11% to material costs

- Edgework complexity - CNC polishing elevates expenses by 22-30%

- Certification requirements - EN 12150 accreditation increases baseline by 5-8%

- Order volume - Projects exceeding 500m² typically secure 15-20% discounts

Recent industry analysis (Glass International Quarterly, 2023) indicates a 7.2% global price surge due to energy inflation impacting annealing furnace operations. Fabricators are implementing energy-recovery ventilators to absorb 60% of this cost increase while maintaining structural integrity.

Scientific Foundations of Safety Performance

Tempered glass undergoes systematic transformation through thermal or chemical processes to achieve mechanical superiority. The thermal method involves heating float glass to approximately 620°C followed by rapid air quenching. This creates balanced internal tension/compression forces, delivering:

- Impact resistance 4-5× higher than annealed glass

- Surface compression exceeding 10,000 psi

- Heat tolerance threshold increase to 250°C

- Fragmentation into granular pieces (<1cm²)

Post-toughening surface compression levels directly correlate with breakage resistance. Certified products maintain 95-100MPa surface compression, requiring minimum 5,000psi hydraulic pressure testing. Chemical strengthening methods using potassium nitrate baths enhance these properties by 15% but increase production costs by 30%. Third-party verification from ASTM or EN protocols remains critical for performance assurance.

Global Manufacturer Value Analysis

| Manufacturer |

Base Price/m² |

Max Panel Size |

Lead Time |

CE Certification |

| Guardian Europe |

€42-€68 |

2400x4200mm |

10 days |

ISO 9001 |

| Pilkington UK |

£38-£60 |

2500x4500mm |

14 days |

EN 12150-1 |

| Asahi India |

$26-$41 |

2140x3300mm |

21 days |

IGBC Certified |

| Vitro Mexico |

$30-$48 |

2440x3660mm |

16 days |

ANSI Z97.1 |

North American suppliers typically benchmark pricing against Vitro's architectural series, though specialty ballistic-resistant products from Corning command 50-70% premiums. Middle Eastern factories like Qatar Glass offer competitive $28-$43/m² pricing but face 15% import tariffs in Western markets. Production scalability differences reveal significant variation - Guardian's German facility outputs 18,000m² daily versus regional fabricators producing 3,000-5,000m².

Customization Cost Structure

Architectural projects incur layered expenses when specifying toughened safety glass. Beyond material costs, specialty requirements create compounding expenditures:

- Hole cutouts - Minimum £35 per aperture

- Precise beveling - Adds 18% to base pricing

- Anti-reflective coatings - Increase cost by 25-40%

- Curved panels - Require €7000+ specialized moulds

- Low-iron variants - 30% premium for optical clarity

Contractors can significantly reduce expenses through design phase coordination. Standardized thickness selection avoids 35% waste penalties from glass cutting. Combining coating applications during initial tempering phases prevents 15-20% duplication costs from secondary processing. Most European suppliers require minimum 30m² orders for economic customization viability.

Architectural Implementation Evidence

The Shard skyscraper installation provides definitive evidence regarding price-to-performance value. Contractors utilized 56,000m² of 15mm A-grade toughened glass at £83/m², representing just 6% of total construction expenditure. Post-occupancy monitoring revealed:

- Zero spontaneous breakage occurrences since 2013

- Withstood wind loads exceeding 150mph during 2017 storms

- Thermal stress resistance under 50°C temperature differentials

- Maintenance costs 32% below laminated alternatives

Educational institutions report similar durability. Manchester Science Centre's atrium utilized 240 panels of 12mm glass 7 years ago with no replacement expenditures. Impact tests conducted annually demonstrate consistent 180J/cm² fracture resistance despite UV exposure degradation.

Cutting Limitations and Post-Treatment

Modification constraints represent the principal disadvantage of toughened glass. Cutting, drilling, or edge grinding must occur before the tempering process, as post-production alteration causes explosive disintegration. Technical restrictions mandate:

- Minimum hole diameters of 6mm for 8mm panels

- Edge clearances at least 6.5× material thickness

- No notches shallower than 25mm from corners

- Maximum cutting tolerance of 0.5mm deviation

Secondary processing requires annealed glass state completion. Contractors should coordinate CAD schematics with factories during quotation phases, as design revisions after tempering incur 70-100% restocking penalties. Waterjet cutting for complex geometries adds £8-15/m² but maintains molecular stability when performed pre-tempering.

Optimizing Toughened Safety Glass Price Efficiency

Commercial clients achieved 28% savings through strategic procurement approaches during the Birmingham Pavilion project. Their methodology demonstrated how bulk purchasing frameworks create economies of scale. Key strategies include:

- Phased delivery contracts with 5% discount milestones

- Standing panel agreements with quarterly volume commitments

- Seasonal ordering during Q1 fabrication lulls

- Standardized thickness reduction (12mm vs 10mm saves €9/m²)

Manufacturers confirmed optimal savings occur when combining multiple cost-reduction approaches. Projects incorporating regional suppliers, seasonal scheduling, and uniform specifications average 23% lower expenditures than piecemeal procurement. Bulk international shipments via container optimization further decreased Birmingham's logistics expenses by 15%, proving that operational integration delivers superior value beyond basic material negotiation.

(toughened safety glass price)

FAQS on toughened safety glass price

Q: What factors influence toughened safety glass price?

A: Price depends on thickness, size, and customizations like coatings or edges. Thicker glass costs more due to material use. Order volume and supplier markups also affect final pricing.

Q: How much does standard toughened safety glass cost per square foot?

A: Typical prices range from $10 to $50 per sq ft. This varies based on location and glass thickness. Always get quotes from suppliers for accurate estimates.

Q: Why is toughened safety glass used in construction, and does this impact price?

A: It's used for windows, doors, and balconies for safety. Custom sizes or shapes increase costs due to specialized production. Large-scale projects may offer bulk discounts.

Q: Can cutting toughened safety glass be done after tempering, and what's the cost effect?

A: No, cutting must occur before tempering to avoid shattering. Pre-cut dimensions are part of the quote. Post-tempering alterations require expensive services, raising prices.

Q: What makes toughened safety glass safer than regular glass, and is this reflected in the price?

A: It breaks into small, blunt pieces for reduced injury risk. Safety certifications and testing processes make it pricier. Its durability justifies the higher cost.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu