The Rise of Toughened Glass A Look Into the Future of Glass Manufacturing

In recent years, toughened glass has emerged as a material of choice across various industries, and the demand for toughened glass companies has surged. From architecture to automotive, toughened glass is celebrated for its strength, safety, and versatility. This article explores the significance of toughened glass, the process of its production, and the potential future of the industry.

Toughened glass, also known as tempered glass, is made through a thermal treatment process that increases its strength compared to normal glass. The glass is heated to high temperatures and then rapidly cooled, which creates a balance of internal stresses. This process not only enhances the glass's resistance to impact and thermal stress but also makes it safer. When broken, toughened glass shatters into small, blunt pieces that are less likely to cause injury, making it an ideal choice for a variety of applications.

The Rise of Toughened Glass A Look Into the Future of Glass Manufacturing

In the automotive sector, toughened glass has found its place in the manufacturing of windscreens and side windows. As car manufacturers focus on making vehicles safer, tougher glass provides a robust solution that can withstand impacts and harsh weather conditions. Furthermore, with the rise of electric vehicles, the demand for panoramic roofs and large windows has increased, further driving the need for toughened glass products.

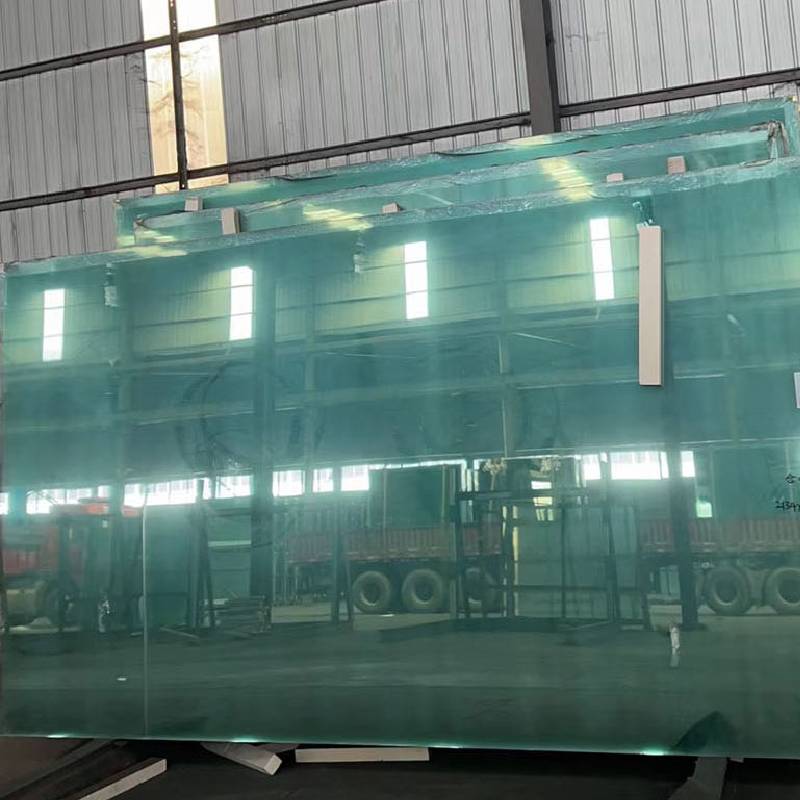

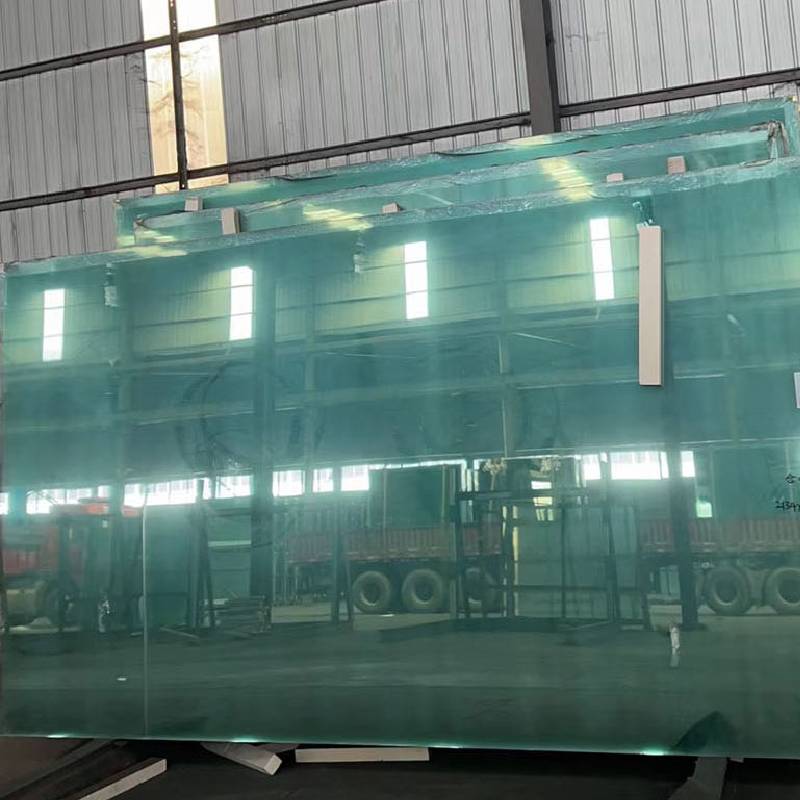

toughened glass company

The production process of toughened glass begins with high-quality raw materials, primarily silica sand, soda ash, and lime. These materials are fused together in a furnace at temperatures exceeding 1,500 degrees Celsius. Once the molten glass has been formed into sheets, it undergoes the tempering process, which involves heating it again to about 620 degrees Celsius before rapidly cooling it down. This essential step ensures that the glass achieves its characteristic strength and safety features.

Innovation in the toughened glass industry is crucial to meet the growing demands of various sectors. Companies are investing in advanced manufacturing technologies, including automated production lines and cutting-edge quality control mechanisms. Additionally, the incorporation of smart technologies into glass, such as electrochromic or photochromic capabilities, presents exciting possibilities for the future. These innovations not only enhance the functionality and aesthetic appeal of toughened glass but also align with the global trend toward smart buildings and homes.

However, the rise of toughened glass companies is not without challenges. The competition is fierce, with numerous manufacturers entering the market. To stay ahead, companies must focus on quality, sustainability, and customer service. Eco-friendly production processes and recycling initiatives are becoming increasingly important in ensuring that glass manufacturing contributes to a circular economy.

In conclusion, toughened glass is revolutionizing various industries with its unique properties and adaptability. As technology advances and consumer preferences evolve, toughened glass companies are poised for significant growth. The future looks promising for this industry, which combines innovation with sustainability to create safer and more beautiful living and working environments. As architects, builders, and manufacturers continue to explore the potential of toughened glass, we can expect remarkable developments that will shape our surroundings for years to come.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu