The Cost of Low Iron Glass An Overview

In today’s architectural and design landscape, low iron glass has emerged as a popular choice for both residential and commercial projects. Renowned for its clarity and aesthetic appeal, this type of glass is fundamentally different from traditional glass due to a reduced iron content. The primary advantage of low iron glass is its enhanced transparency, allowing for greater light transmission and a more unobstructed view. However, understanding the cost implications associated with low iron glass is essential for any stakeholder in construction, architecture, or design.

Understanding Low Iron Glass

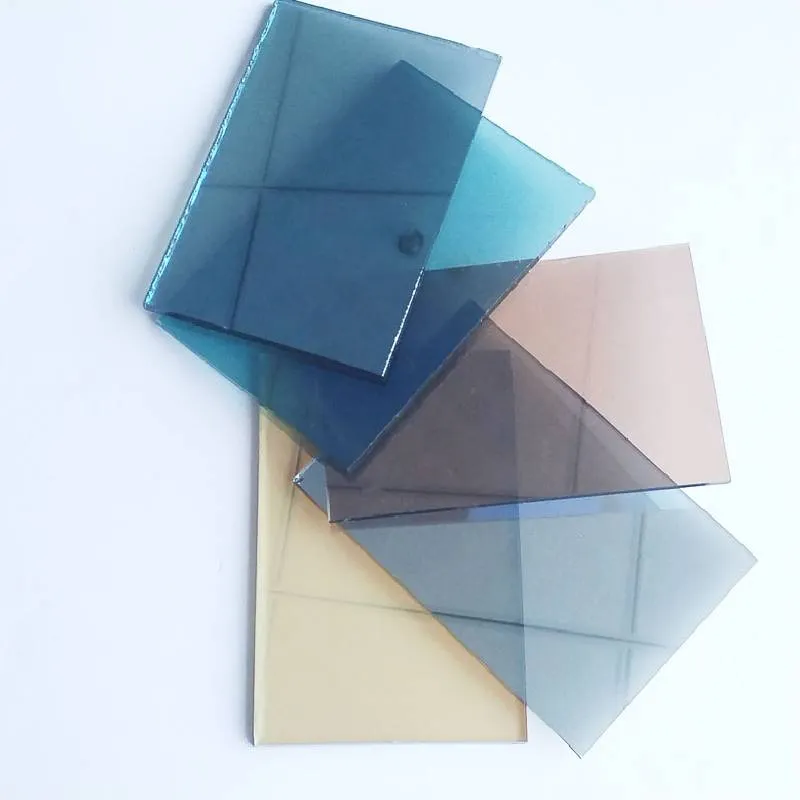

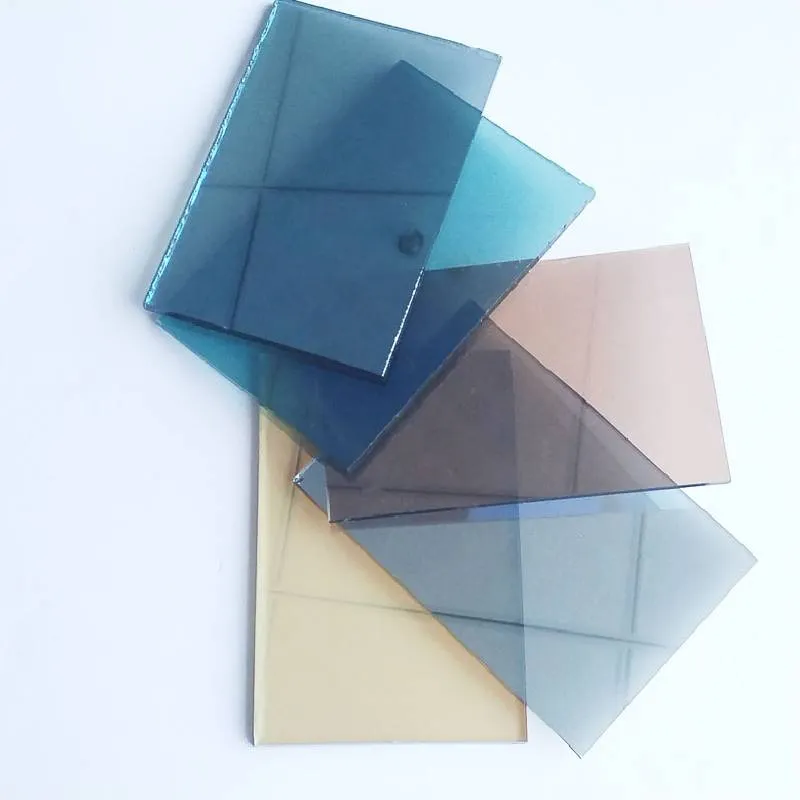

Low iron glass, often referred to as ultra-clear glass, is achieved by reducing the iron oxide content during the glass manufacturing process. Whereas normal float glass contains higher levels of iron, which can give it a greenish tint, low iron glass maintains a crystal-clear appearance that is favored in modern design. Its aesthetic qualities make it ideal for applications such as facades, skylights, and glass railings, where visibility and light transmission are paramount.

Factors Influencing Cost

The cost of low iron glass can vary widely based on several factors

1. Raw Materials The primary components in the production of low iron glass are silica sand, soda ash, and limestone. The purity of these raw materials impacts the final product's clarity and strength. High-quality raw materials can drive up production costs, consequently affecting the price of the end product.

2. Manufacturing Process The production of low iron glass requires advanced technology and specialized equipment. The manufacturing process is more complex than that of standard glass due to the precise control needed to ensure low iron content. This complexity often results in higher manufacturing costs.

3. Thickness and Size Low iron glass is available in various thicknesses and sizes. Custom dimensions or thicker glass will not only increase material costs but also lead to greater transportation and handling fees. Architects and designers must carefully consider these variables when budgeting for low iron glass.

cost of low iron glass

4. Finishing Options Additional processes, such as tempering, laminating, or coating, can further increase the cost. These finishing options enhance the glass's strength, safety, and functionality but require additional investments in processing and materials.

5. Supplier and Market Demand Just like any commodity, the price of low iron glass is influenced by market demand and the supplier's pricing strategy. In regions where low iron glass is in high demand or where few suppliers operate, prices can be significantly elevated.

Cost Comparison with Standard Glass

When compared to standard glass, low iron glass typically comes at a premium price. A rough estimate suggests that low iron glass can cost between 20% to 50% more than standard float glass, depending on the specific project requirements and local market conditions. However, many industry professionals argue that the benefits of low iron glass justify the higher cost. Its superior visual quality often leads to increased property value, improved energy efficiency through better light transmission, and enhanced design flexibility.

Economic Benefits

Investing in low iron glass can yield long-term economic benefits, particularly in energy savings and maintenance. Because low iron glass allows more natural light to enter a building, it can reduce reliance on artificial lighting, leading to lower energy bills. Additionally, its durability and resistance to environmental factors can minimize the need for frequent replacements or repairs.

Conclusion

In conclusion, while the cost of low iron glass is higher than that of standard glass, the advantages it offers in terms of aesthetics, energy efficiency, and overall performance can make it a worthwhile investment. As the demand for high-quality, sustainable building materials continues to grow, understanding the cost implications and benefits of low iron glass will be crucial for architects, designers, and builders. By factoring in these considerations, stakeholders can make informed decisions that align with their project goals and budget constraints.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu