Aluminum Mirror: Industry Trends, Technical Analysis, Manufacturer Comparison & Custom Solutions

1. Market Overview & Industry Trends

The global aluminum mirror market is experiencing accelerated growth, fueled by rising demands across industries such as construction, automotive, interior design, and energy. With its distinctive features such as exceptional reflectivity, corrosion resistance, and lightweight structure, aluminum mirror is increasingly chosen over traditional silver and glass mirrors, especially in humid, alkaline, and industrial environments.

- 🌍 Market Size: In 2023, the worldwide architectural mirror market reached USD 4.8 billion, with aluminum mirror glass taking a rapidly increasing share (source: Markets Insider).

- 📈 Annual Growth: 2021-2023 CAGR for global aluminum mirror glass: ~6.5%. Asian market leads with 8%+ CAGR.

- 🏢 Key Applications: Commercial windows, high-speed rail, solar power reflectors, decorative walls, elevators, shipbuilding, and laboratories.

- 💡 Popular Types: Black aluminum mirror, anti-fog aluminum mirror, aluminium mirror glass with eco-friendly coatings.

- 🧩 Major Players: Guardian, SHZR Glass (China), AGC, Jinjing Group, Yantai Zhenshi.

2. Core Principles of Aluminum Mirror & Technical Parameters

2.1 What is an Aluminum Mirror?

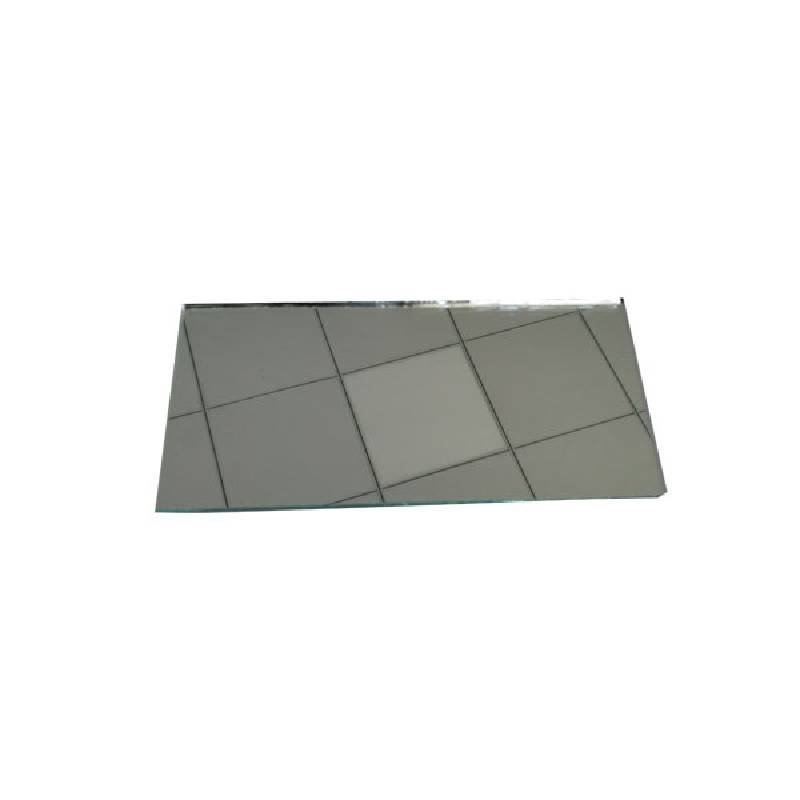

An aluminum mirror is produced by uniformly depositing an ultra-thin aluminum layer (99.8–99.99% pure) onto float glass via advanced vacuum evaporation or magnetron sputtering. The aluminum layer is sealed and protected by a multi-layered coating (protective lacquer, anti-corrosion paint, UV curing), ensuring high reflectivity and environmental resilience.

2.2 Main Technical Specifications Table

| Parameter | Specifications | Industry Standard |

| Reflectivity | 85%–92% (Visible), 92%–95% (UV-Blue) | ISO 9050, ANSI Z97.1 |

| Aluminum Purity | ≥99.8% | JEITA EM-3508 |

| Coating Thickness | 60–120 nm (Al), 20–45 μm (lacquer+paint) | ASTM C1347 |

| Glass Thickness | 2 mm, 3 mm, 4 mm, 5 mm, 6 mm | EN 572-1 |

| Scratch Resistance | >6H Pencil Hardness | ISO 15184 |

| Anti-Corrosion | 48h–336h (Salt Spray) | ISO 9227 |

| Service Life | 10–25 years (Indoor/Outdoor) | — |

| Sheet Size | Max 3300x2140 mm; custom cutting | Client Spec |

| Light Transmission | <3% | ISO 9050 |

2.3 Advanced Materials and Production Process

- Substrate: Premium low-iron or float glass; lower FeO for increased clarity.

- Aluminum Coating: High-vacuum evaporation/magnetron sputtering for uniform atomic-scale deposition.

- Protective Lacquer: Non-lead, eco-friendly, double-layer (water-based and oil-based options).

- Testing: Every batch inspected for reflectivity (photometric), adhesion (cross-cut test), and anti-fog performance.

- Certifications: ISO 9001:2015 (QMS), SGS, CE, ANSI/EN glazing standards.

3. Aluminum Mirror Manufacturing Process Flow

-

Raw Glass Cutting

Float/Low-iron glass selection

-

Super-polishing

Edge grinding, surface washing

-

Aluminum Deposition

Vacuum evaporation/ magnetron sputtering

-

Sealing & Curing

Protective lacquer, triple-bake

-

Inspection & Testing

Reflectivity, adhesion, anti-scratch

-

Custom Cutting

CNC, waterjet, laser available

-

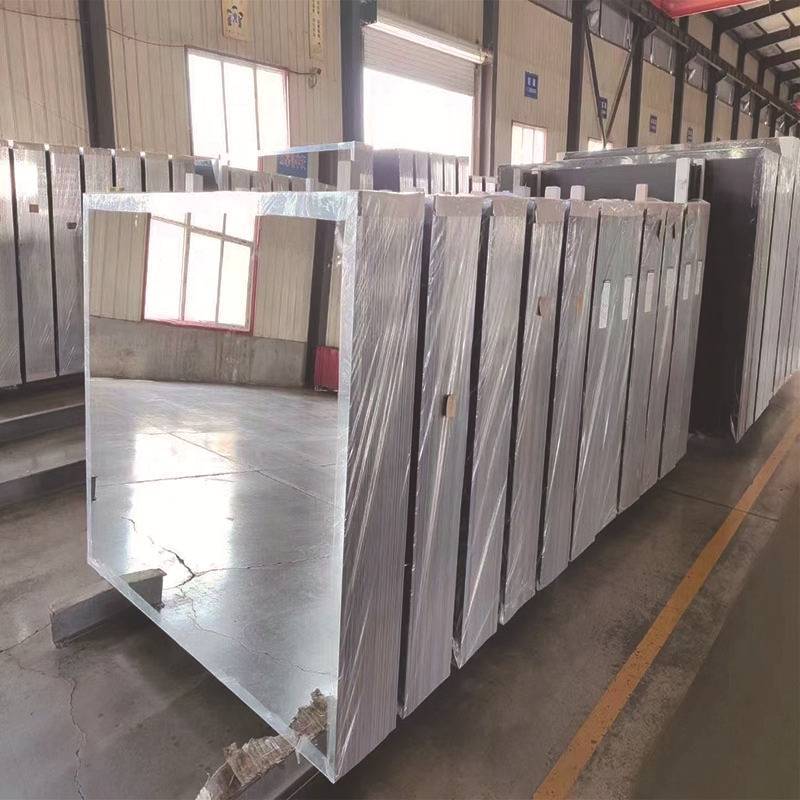

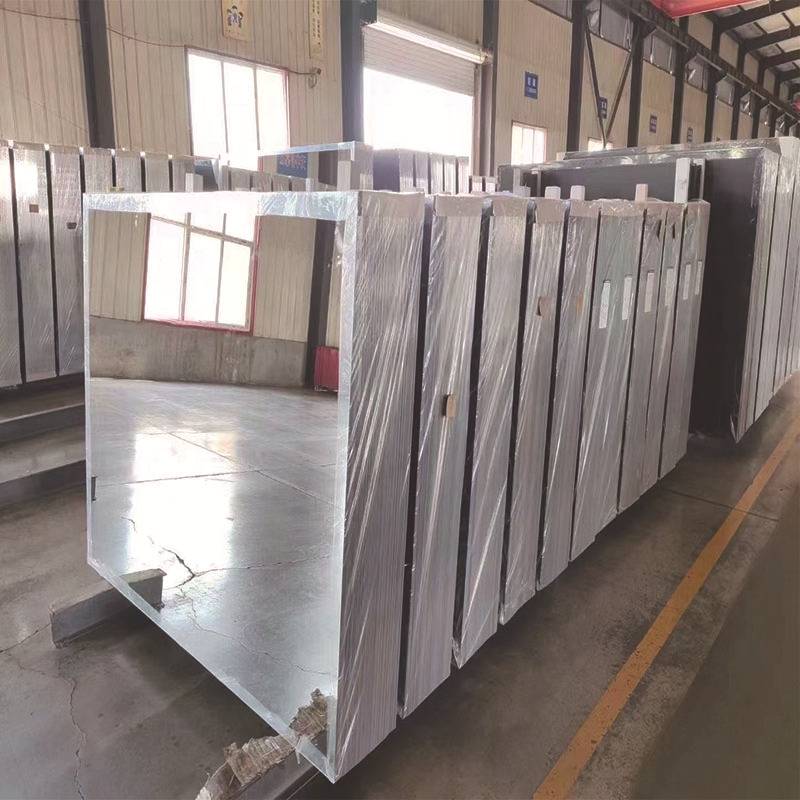

Packing & Delivery

ISO-certified safety packages

- Advanced Sputtering: Magnetron process enables atomic-level smoothness and ≥90% reflectivity stability.

- Sealing & Baking: Automated UV and infra-red baking lines ensure coating adhesion and scratch resistance.

- Quality Control: Each mirror undergoes robotized visual and micron-thickness inspection.

CNC custom machining is offered for bespoke mirror shapes, drilling, edge grinding, and polished bevels, all while maintaining full compliance with ISO, ANSI, EN standards for safety and performance.

4. Why Choose Aluminum Mirror?

- 🌀 High Reflectivity: Visible spectrum reflectance up to 92%, surpassing most silvered float mirrors.

- 🛡️ Corrosion Resistance: No tarnish in alkaline, salt-spray, or humid environments. Ideal for coastal or chemical industries.

- 🌱 Eco-friendly: Lead-free coatings, recyclable glass and aluminum, compliant with RoHS, SGS.

- ⚡ Lightweight & Durable: Lower density than silver, better impact resistance, life cycle up to 2.5 decades.

- 🌡️ Thermal Stability: Resilient in -40°C to +80°C temperature swings, no delamination.

- 🧯 Fire & UV Resistant: Non-flammable materials, anti-fading coatings.

Recommended for bathrooms, hospitals, energy projects, and any architecture needing robust, corrosion-proof, and long-life mirrors.

5. Application Scenarios: Real Case Studies

- Stone & Chemical Factories: Applied as splashback and reflective paneling due to chemical resistance.

- Public Bathrooms & Pools: Mold-resistant and anti-fog variants outperform silver mirrors.

- Rail Transit: Black aluminum mirror — preferred for interior, elevator walls for anti-scratch & anti-fingerprint utility.

- Solar Power: High-reflective large-format aluminium mirror glass boosts panel efficiency (up to 94% UV reflection).

- Commercial Facades: Custom color/aluminum thickness designs increase architectural distinction.

Customer Feedback Excerpt:

"Switching to SHZR's custom

aluminum mirror glass reduced replacement costs by over 40% in our oil refinery washroom – no more corrosion issues in two years."

– Senior Facilities Engineer, Sinopec, 2023.

6. Product Feature Comparison & Visual Data Analytics

6.1 Aluminum Mirror vs. Other Mirrors: Comparative Table

| Feature | Aluminum Mirror | Silver Mirror | Stainless Mirror | Acrylic Mirror |

| Reflectivity (Visible) | 85%–92% | 87%–94% | 60%–70% | ~83% |

| Corrosion Resistance | Excellent | Moderate | Good | Poor |

| Price (Relative) | $$ | $$$ | $$$$ | $ |

| Thickness Range | 2–6 mm | 2–10 mm | 0.8–5 mm | 1–3 mm |

| Custom Cutting | ✓ | ✓ | △ | ✓ |

| Service Life | 10–25 yrs | 8–15 yrs | 25+ yrs | 2–7 yrs |

| Recommended Scene | Industrial, Wet, Outdoor | Indoor, Decor | High-impact | Temporary, Toys |

6.2 Data Visualization: Technical Metrics Analysis

7. Manufacturer Comparison & Customization Solutions

- SHZR Glass (China): 18 years' experience, ISO/ANSI/EN certified, custom sheet size up to 3300x2140 mm, black aluminum mirror series, full CNC processing, ultraclear options.

- Guardian (USA): Strong focus on largescale building glass, less custom finish diversity.

- AGC (Japan/Belgium): Global player, slightly higher aluminium mirror price, advanced low-iron tech.

- Yantai Zhenshi: Domestic China, high cost-performance, limited custom CNC, focus on standard clear series.

| Producer | Certifications | Customization | Lead Time | Key Regions |

| SHZR Glass | ISO9001, CE, SGS | ✔ (shape, color, edge) | 12–18 days | China, Asia, Europe |

| Guardian | ISO9001, ASTM | △ (size only) | 30+ days | America, Global |

| AGC | ISO9001, EN | △ (min. 300㎡ order) | 25–40 days | Europe, Middle East |

| Zhenshi | SGS | △ | 15–30 days | China Only |

Aluminum mirror manufacturers feature various production capacities, but Aluminum Mirror Glass China Factory Custom Wholesale stands out for speed, flexibility, technical backup and full compliance with international standards.

8. Customization Cases: Tailored Engineering Solutions

-

Petrochemical Laboratory Walling

Requirement: Resistance to acid vapors, daily cleaning, anti-fogging.

Solution: 99.99% pure aluminum mirror, triple-layer non-lead lacquer, edge-sealed CNC cutouts.

Result: Stable reflectivity (>90% at 2 years), zero edge corrosion.

-

Hospital Restroom Retrofit

Requirement: Anti-bacterial, shatter-resistant, hygiene compliance.

Solution: SHZR's 4 mm black aluminum mirror glass, certified to EN 1036 & ISO 22196, film-backed anti-shatter.

Result: No microbial growth post 2500 cleanings, sparkle finish retained.

-

Solar Reflector Engineering

Requirement: UV reflectivity >93%, endurance to sandstorms.

Solution: High-vacuum deposited aluminum mirror glass, toughened by lamination.

Result: 10% energy yield gain, 24+ months durability in open desert.

9. Pricing & Delivery

-

Aluminium Mirror Price (Reference, 2024):

- 2 mm: $10–$13/m² (standard); 4 mm: $16–$22/m² (custom finish)

- Black aluminum mirror: +8% premium over standard

- Bulk/wholesale: Disounts available for 100+ m² or regular order

-

Delivery: Rapid tracks: 12–18 business days for custom batches. CE/SGS-certified packaging, export compliance (ISPM15 for wood crates).

-

Warranty: Up to 8 years product guarantee depending on finish. After-sales support and technical consulting.

-

MOQ: 10 m² for most product lines; custom orders negotiable.

10. Frequently Asked Questions: Professional Technical FAQ

-

Q1: What is the typical substrate glass for aluminum mirror production?

A: Usually 2–6 mm float glass (EN 572-1 compliant), with ultra-clear/low iron glass for high-end applications (e.g., laboratory, solar use).

-

Q2: Can the aluminum mirror withstand humid and alkaline environments?

A: Yes. Thanks to advanced double-layer protective lacquers and high-purity aluminum, the product easily passes >336h salt-spray and 85% humidity ASTM tests.

-

Q3: What installation standards apply?

A: Follow EN 1036, ISO 5713, and ANSI Z97.1 for mounting; use neutral silicon adhesives, avoid edge exposure, and provide expansion space for large panels.

-

Q4: What is 'pencil hardness' and what does it mean for scratch resistance?

A: Pencil hardness shows a coating's resistance to scratches. 6H/7H means high resistance; SHZR aluminum mirror glass achieves >6H via UV-cured lacquers.

-

Q5: How is anti-fog performance ensured for mirrors in bathrooms/saunas?

A: By special nano-coatings or external anti-fog films during the final stage, preventing condensation/fogging in high-humidity environments.

-

Q6: What certifications are available for SHZR aluminum mirror?

A: ISO9001 (QMS), CE (EN 1036), SGS anti-lead/ROHS, and custom certificates for chemical/medical use as needed.

-

Q7: Are custom shapes, edge finishing, or holes possible?

A: Yes. Full CNC, waterjet, and laser processing enables any size/shape, including notches, beveled edges, rounded corners, and integrated assembly holes.

11. Customer Support, Guarantee, Authoritative References

-

Service: Technical support, installation consulting, after-sales rapid feedback (aluminum mirror hotline, WeChat, email, video calls available).

- Quality Assurance: Defective glass returned/replaced free within 45 days. On-site inspection by SGS on request.

- Partnerships: Projects in partnership with top design institutes and listed companies across Europe, Middle East, Asia-Pacific.

Industry Authority Citation:

"Best practices in architectural mirrors increasingly favor aluminum mirror glass for durability and anti-corrosion—the difference in lifecycle cost is especially significant for institutional and coastal projects."

–

Glassonweb Technical Forum

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu