The Art and Science of Making Tempered Glass

Tempered glass, also known as toughened glass, is a type of safety glass that has been treated by controlled thermal processes to increase its strength compared to normal glass. Its remarkable durability and resistance to thermal shock make it an essential material in various applications, from automotive windows to building facades. Understanding the process of making tempered glass reveals a fascinating interplay between art and science, showcasing both craftsmanship and advanced technology.

The Manufacturing Process

The journey to creating tempered glass starts with the selection of raw materials. Standard glass is primarily made from silica sand, soda ash, and limestone. These materials are carefully mixed and melted at high temperatures, typically around 1700 degrees Fahrenheit (about 927 degrees Celsius), in a furnace. The molten glass is then formed into sheets through various processes, including casting, blowing, or rolling. At this stage, the glass is still untempered and relatively weak.

Once the glass sheets are formed and cooled, they undergo the tempering process, which involves both heating and rapid cooling. This is where the transformation from standard glass to tempered glass occurs. Here’s how it works

1. Heating The glass sheets are placed in a tempering oven, where they are uniformly heated to temperatures exceeding 1,000 degrees Fahrenheit (about 538 degrees Celsius). This heating phase is crucial, as it allows the glass to reach a state where its internal structure can be rearranged to enhance strength.

2. Quenching After reaching the desired temperature, the glass sheets are rapidly cooled using high-velocity air jets. This process, known as quenching, causes the outer surface of the glass to cool and harden faster than the inner layers. As the outer layers solidify, they contract and become under tension, while the inner layers remain at a higher temperature and are under compression. This tension-compression balance is what gives tempered glass its strength.

3. Inspection and Cutting Once tempered, the glass is inspected for quality, ensuring it meets safety standards for thickness, clarity, and structural integrity. If cutting is necessary, it must be done before tempering, as cut edges of tempered glass cannot be altered—attempting to cut tempered glass after it has been processed may lead to spontaneous shattering.

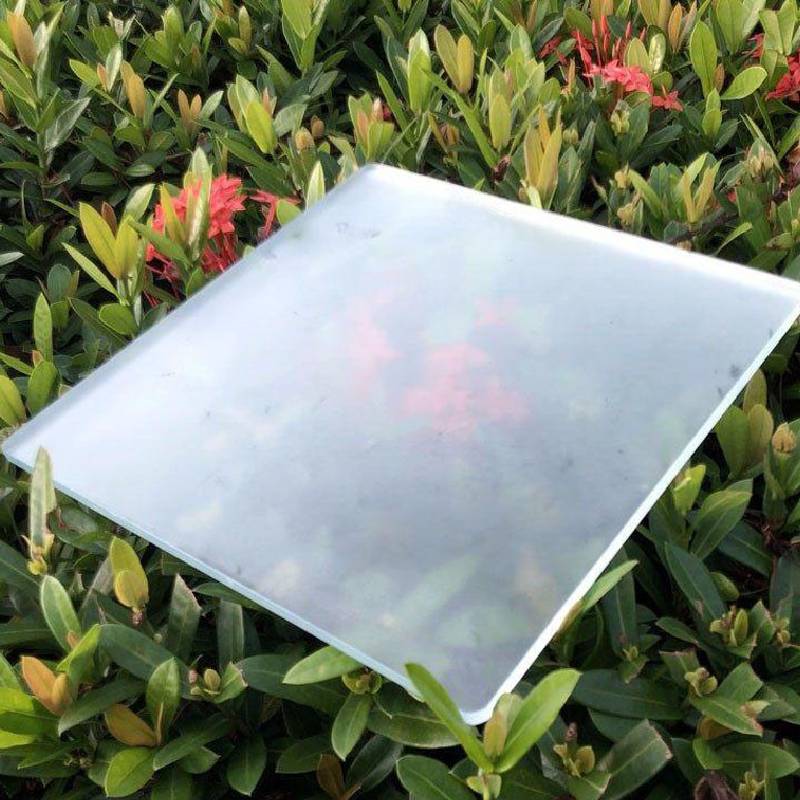

making tempered glass

Applications of Tempered Glass

The inherent strength and safety characteristics of tempered glass make it suitable for a wide range of applications. In both commercial and residential construction, tempered glass is used for windows, doors, and partitions. Its ability to withstand extreme temperature changes makes it perfect for use in shower doors and glass facades. Furthermore, its shatter-resistant properties enhance safety in environments such as schools and hospitals.

In the automotive industry, tempered glass is used in windshields and side windows, providing drivers and passengers with enhanced safety. In the event of an accident, tempered glass crumbles into small, blunt pieces, reducing the risk of severe injury.

Benefits and Limitations

Tempered glass offers numerous benefits, including high resistance to impact, thermal stress, and extreme temperatures. Its strength means it can often be made thinner than standard glass while still providing the same level of safety and performance, which can save on material costs in construction.

However, there are limitations to consider. While tempered glass is much stronger than regular glass, it is not invulnerable. It can still be broken under significant force or by specific types of impact. Additionally, the production process is more expensive than that of standard glass, which can impact budgeting for projects that require large quantities.

Conclusion

The art of making tempered glass combines traditional craftsmanship with modern engineering techniques. Understanding its manufacturing process sheds light on why tempered glass is such a valuable material across various industries. With its incredible strength, durability, and safety features, tempered glass continues to be a preferred choice for those looking to enhance both aesthetics and security in their projects. Whether it’s a skyscraper, a luxury car, or a shower stall, the benefits of tempered glass are evident, making it a remarkable material of our time.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu