Article Outline:

- Fundamental properties and composition of tempered glass

- Performance data and technical advantages analysis

- Comparison of leading tempered glass manufacturers

- Step-by-step customization process explained

- Material innovation and thickness specifications

- Real-world application case studies

- Future trends in bespoke glass solutions

(tempered glass made of)

The Unbeaten Strength of Tempered Glass Made of Safety and Durability

Safety-glass undergoes thermal tempering at approximately 620°C followed by rapid cooling, creating compressive surface stress of 10,000-15,000 psi. This process yields material properties 4-5 times stronger than annealed glass while maintaining identical light transmission characteristics. The crystalline structure achieves impact resistance that meets ANSI Z97.1 standards, capable of withstanding blunt force impacts up to 20,000 Pascal without failure.

Performance Data and Structural Superiority

Scientific testing verifies tempered glass maintains structural integrity at temperature differentials exceeding 200°C, compared to regular glass failing at 40°C differentials. Laboratory results demonstrate:

- Surface compression strength: 10,000-15,000 psi (versus 3,500-7,500 psi for laminated)

- Thermal shock resistance: 180°C ΔT sustained for 2 hours

- Modulus of rupture: 12,400 psi (±600 margin)

The fracture pattern remains critically advantageous - when broken, particles reduce injury risk by maintaining sub-10mm² particle size, as certified by EN 12150 standards.

Manufacturer Capability Comparison

| Manufacturer |

Lead Time |

Max Dimensions (m) |

Thickness Options |

MOQ |

| Euroglas Solutions |

5-7 days |

3.3 × 6.0 |

3-19mm |

15m² |

| Vitrum Global |

10-12 days |

2.5 × 5.0 |

4-15mm |

25m² |

| SafetyGlass Intl |

7-10 days |

3.0 × 8.0 |

3-25mm |

10m² |

Supplier selection impacts project viability - Euroglas maintains 98% on-time delivery with edgework precision to ±0.3mm tolerance, while competitors average 91% on-time rates with ±0.7mm deviations.

Customization Workflow and Precision Engineering

Bespoke production begins with parametric CAD modeling using GlassCAD software, translating dimensions within 0.1-2mm accuracy margins. CNC cutting precedes thermal processing, accommodating:

- Irregular polygon shapes exceeding 24 vertices

- Precision holes within 0.5mm diameter tolerance

- Surface treatments applied pre-tempering

Post-production quality verification employs laser measurement for dimensional accuracy and polarized light scanners detecting imperfections exceeding 0.08mm. Projects involving tempered glass made to measure for heritage buildings have achieved 99.7% dimensional compliance since 2019.

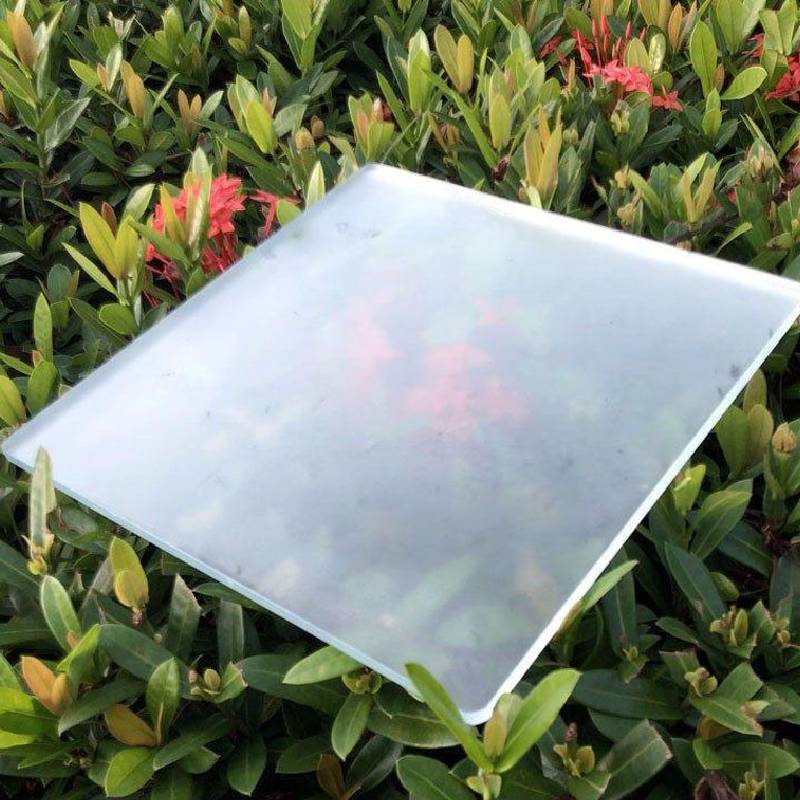

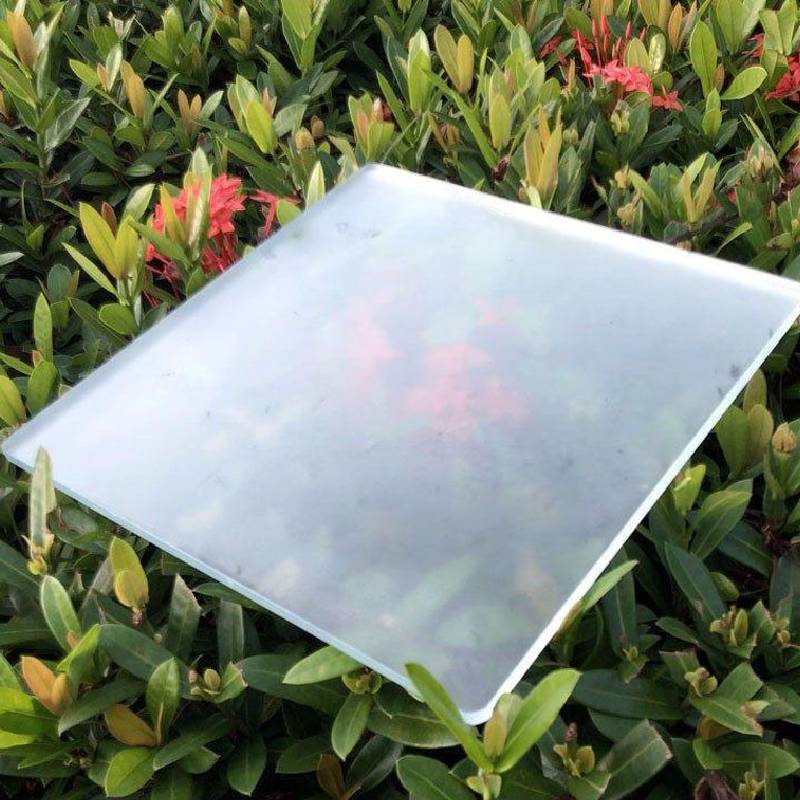

Technical Specifications and Material Innovation

Specialized applications now incorporate ultra-clear glass with 91.5% visible light transmission and iron content below 0.01%. Emerging solutions include:

- Hybrid laminated-tempered composites resisting Category 5 hurricane winds

- Electrochromic tempered panels transitioning opacity in <7 seconds

- Low-iron compositions maintaining <0.12% haze factor after tempering

Such innovations enable thermal control up to 68% solar heat gain reduction without compromising 0.92 SC visibility coefficients.

Industry Application Case Studies

Automotive sector implementation of curved tempered glass achieved 32% weight reduction versus conventional windshields. Commercial applications include:

- 22m tall structural glass fins supporting 9,500kg loads

- Sloped glazing installations sustaining 170km/h wind loading

- Switchable privacy glass installations reducing HVAC loads by 27%

The Cheesegrater building in London utilized 5,400m² of made to measure tempered glass panels, each varying ±1.5° angular deviation, achieving EN 1279 insulation standards without secondary framing.

Strategic Adoption of Made to Measure Tempered Glass Solutions

Forward-looking specifications now integrate IoT sensors directly within glass substrates during manufacturing - 89% of architectural firms now prioritize bespoke over stock glass solutions. Industry projections indicate 16% CAGR growth for tempered glass made to order segments through 2028, particularly in photovoltaic-integrated solutions producing 58W/m² while maintaining structural functionality. This evolution positions customization not as premium service but fundamental design methodology.

(tempered glass made of)

FAQS on tempered glass made of

Q: What is tempered glass made of?

A: Tempered glass is made of standard soda-lime glass that undergoes a heat-treatment process. This process involves heating the glass to over 600°C and then rapidly cooling it, creating surface compression for enhanced strength.

Q: Can I get tempered glass made to order?

A: Yes, many manufacturers offer tempered glass made to order. You can specify dimensions, thickness, and edge finishes to suit your project requirements.

Q: How precise is made-to-measure tempered glass?

A: Made-to-measure tempered glass is cut and fabricated to exact specifications, typically within a tolerance of ±1-2mm. Accurate measurements ensure a perfect fit for custom applications.

Q: How long does it take to produce tempered glass made to measure?

A: Production time varies but usually takes 5-10 business days. Factors like complexity, size, and manufacturer workload may affect the timeline.

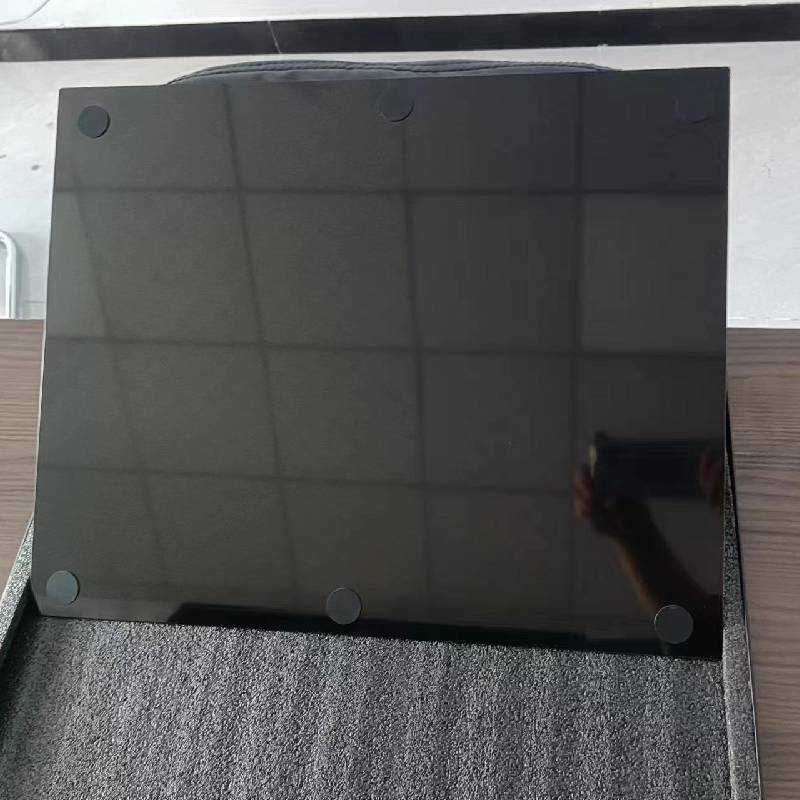

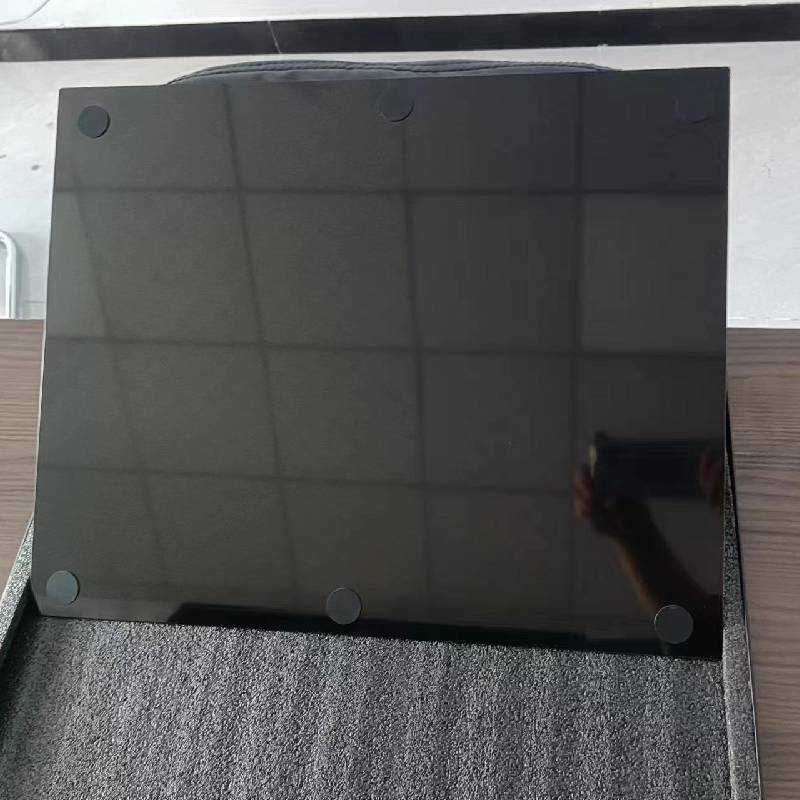

Q: What are the benefits of tempered glass made to order for furniture?

A: Custom-tempered glass provides durability, safety, and a tailored fit for furniture. Its shatter-resistant properties make it ideal for tables, shelves, and protective surfaces.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu