15mm float glass is becoming an increasingly popular choice in the architectural and construction sectors, where its unique attributes are sought after for various innovative applications. Known for its clarity, strength, and versatile use, this particular thickness of float glass offers a combination of aesthetic appeal and robust performance, making it an optimal choice for modern infrastructure projects.

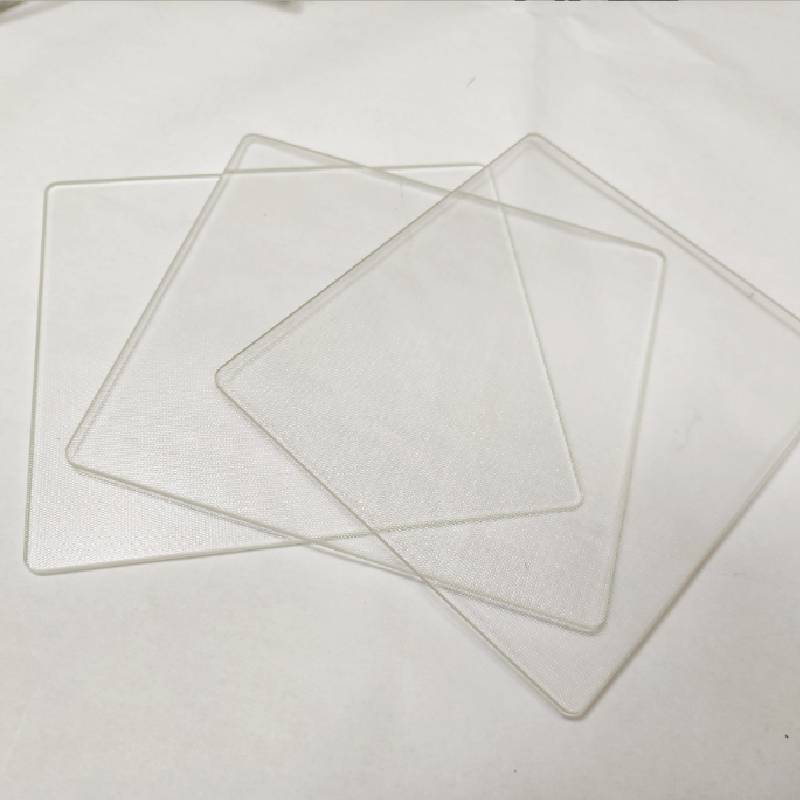

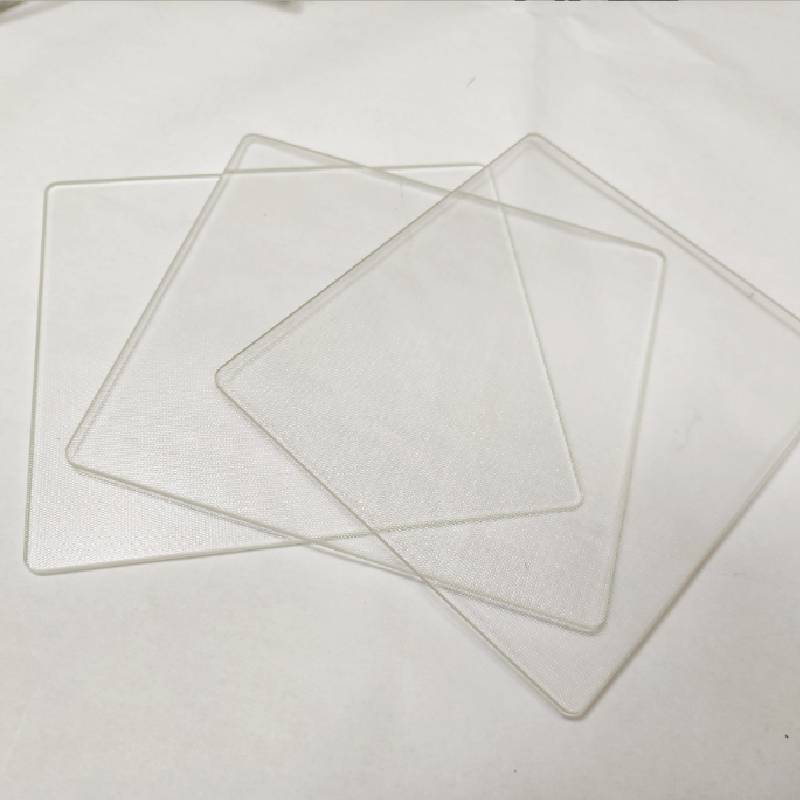

Crafted through a meticulous manufacturing process, 15mm float glass is created by floating molten glass on a bed of molten tin, which results in a perfectly flat surface on both sides. This process ensures a consistent thickness and high-quality finish, distinguishing it from other types of glass. Its dimensional stability and clarity are of paramount importance for ensuring maximum light transmission and transparency, features that are highly valued in both residential and commercial buildings.

When evaluating the structural properties of 15mm float glass, engineers and architects appreciate its impressive load-bearing capacity. This is particularly useful for curtain walls, partitions,

and large glass facades, where both durability and beauty need to coexist. Compared to thinner glass options, 15mm thick float glass can withstand substantial weight and pressure, reducing the risk of breakage and enhancing safety, which adds to the building's overall integrity.

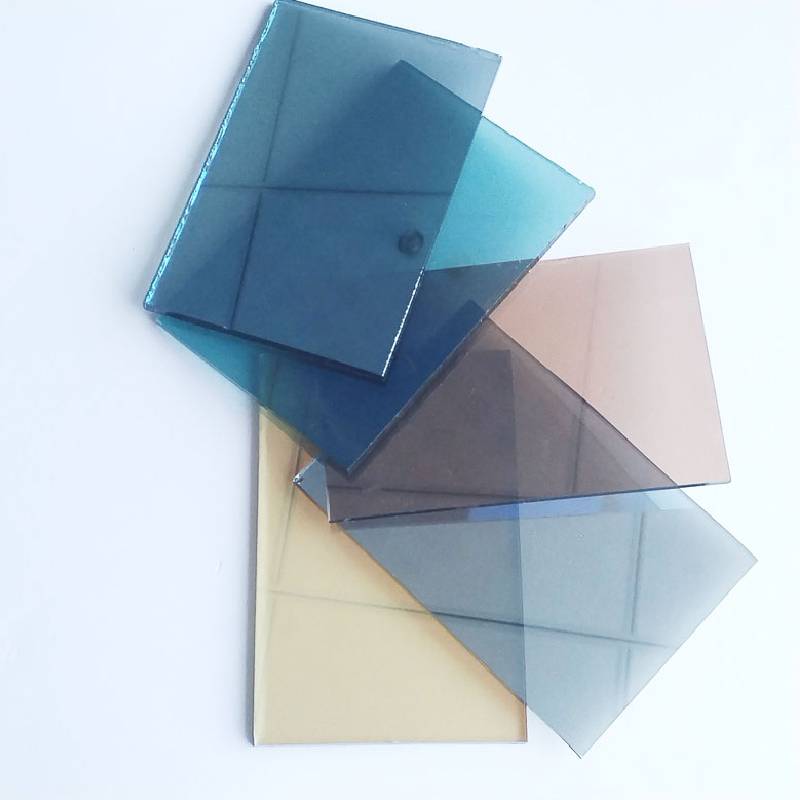

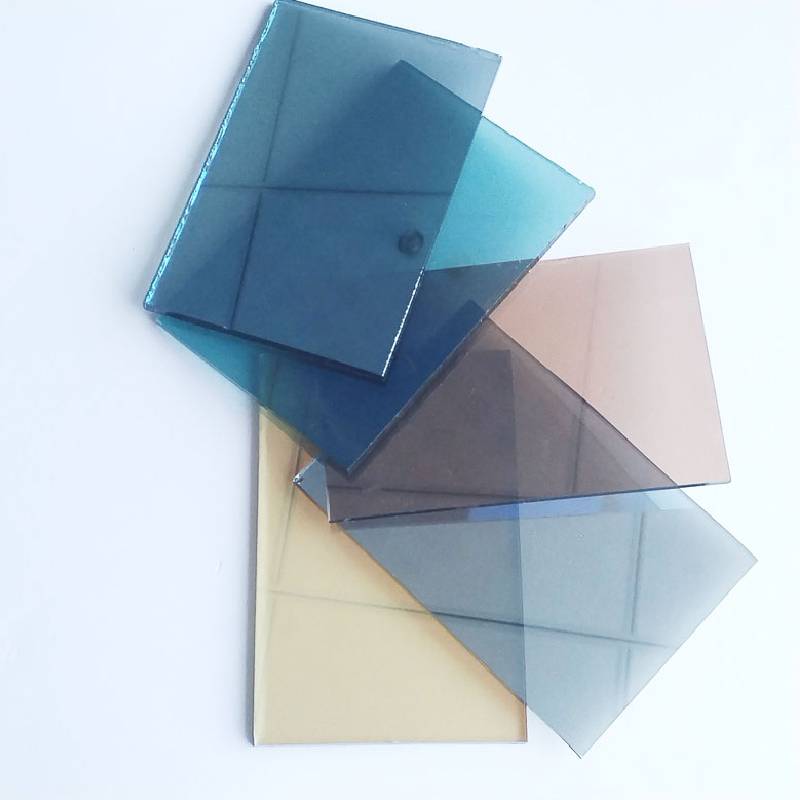

From a design perspective, 15mm float glass offers unparalleled flexibility. Its relatively thick profile allows it to be cut, tempered, laminated, or even bent to fit bespoke architectural needs without compromising its strength or optical clarity. This makes it an excellent choice for creating stunning visual features and complex shapes that are often required in modern construction.

The energy efficiency of 15mm float glass also plays a significant role in its increased adoption. With an enhanced ability to slow the transfer of heat, it contributes significantly to the thermal insulation of a building. This characteristic helps in maintaining the indoor temperature, leading to reduced energy consumption for heating or cooling, thereby supporting sustainable building practices and reducing carbon footprints.

15mm float glass

Experts in sustainable architecture often highlight the recyclability of float glass as another contributing factor to its environmental benefits. The material can be recycled multiple times without losing its inherent properties, making it an eco-friendly choice for projects that aim for green certification.

The trustworthiness of using 15mm float glass is reinforced through rigorous testing and certification processes that ensure it meets global safety and performance standards. Manufacturers provide warranty and quality assurance that underscore their commitment to providing material that not only beautifies a space but also stands the test of time in terms of durability and safety.

Choosing 15mm float glass emerges as a demonstration of expertise in material selection for any project aiming for a sophisticated look combined with practicality. It symbolizes a deep understanding of both traditional craftsmanship and innovative design principles, cementing its status as a preferred material in the building sector.

In summary, the choice of 15mm float glass in construction projects leverages its unique suite of benefits; it is not only an architectural statement but also a strategic decision backed by its technical advantages. From supporting the structural design to enhancing the user experience through improved safety and comfort, this product stands out as a testament to modern advancements in glass technology.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu