The Tempered Glass Process Enhancing Safety and Durability

Tempered glass, also known as toughened glass, is a type of safety glass that has been processed to increase its strength compared to standard glass. The tempering process involves heating the glass to a high temperature, followed by rapid cooling. This method enhances the glass’s strength and makes it more resistant to thermal shock, making it an ideal choice for various applications in construction, automotive, and design.

The tempered glass process begins with the selection of high-quality raw materials. The primary ingredient is silica sand, which is mixed with various additives to improve performance characteristics. Once the mixture is prepared, it is melted at extremely high temperatures in a furnace. This molten glass is then formed into sheets based on the desired thickness and dimensions.

After the glass sheets are formed, they are slowly cooled to room temperature, a process known as annealing. This initial cooling phase is crucial as it removes any internal stresses that may have developed during the heating process. Following annealing, the glass undergoes the tempering process. This involves reheating the sheets to temperatures between 600°C to 700°C. Once the glass reaches the desired temperature, it is rapidly cooled using jets of cold air. This quenching process alters the structure of the glass, creating a compressive stress on the surface while tensile stress exists within the glass. This balance significantly increases the strength of tempered glass.

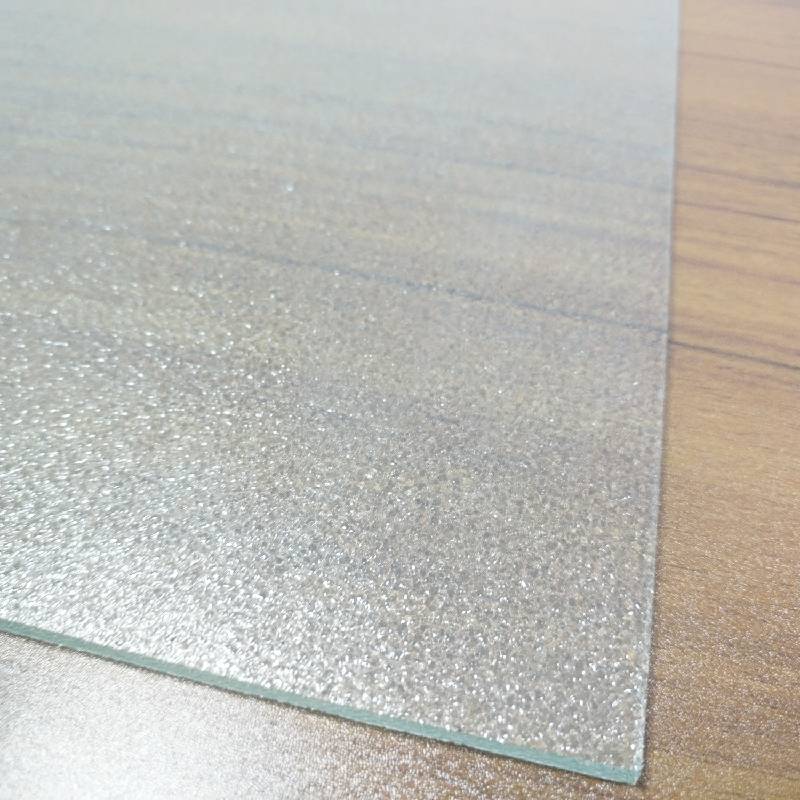

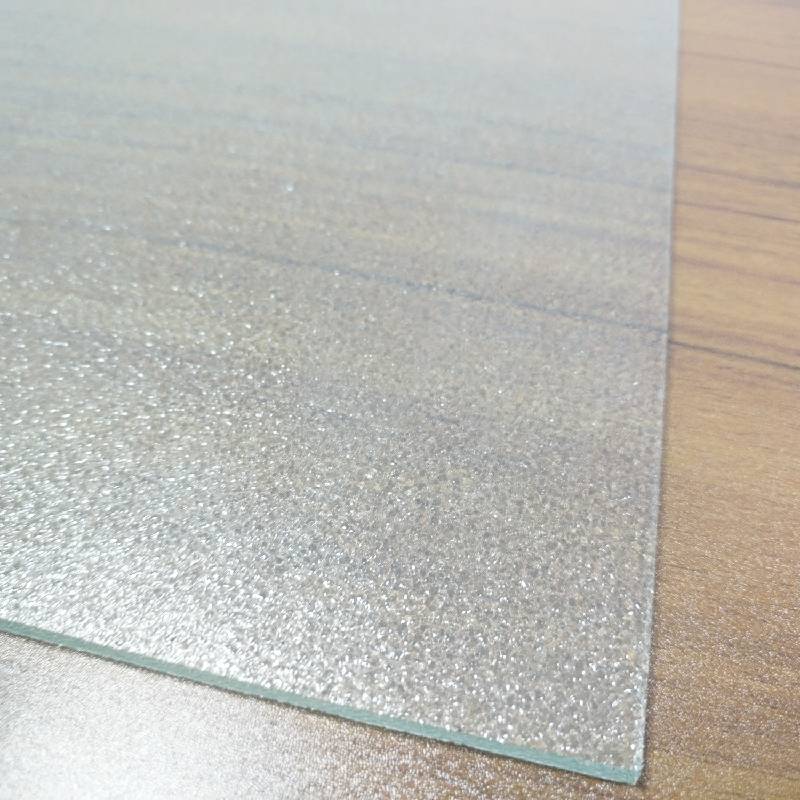

tempered glass process

The superior strength of tempered glass allows it to withstand impact and stress, making it less likely to break compared to standard glass. In the event that it does break, tempered glass shatters into small, blunt pieces, minimizing the risk of injury. This safety feature makes it a popular choice for a wide range of applications, including shower doors, glass facades, and automobile windows.

In addition to safety, tempered glass is also valued for its aesthetic qualities. It can be produced in various finishes and tints, allowing it to complement modern architectural designs. Furthermore, it can be treated with coatings that enhance its thermal insulation and energy efficiency, making it an attractive option in environmentally conscious building projects.

In conclusion, the tempered glass process is a technological marvel that combines safety, strength, and aesthetics, making it a preferred material in many industries. Its unique properties not only enhance the longevity of products but also contribute to safer environments for users.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu