The pricing dynamics of 6mm float glass can be intricate, influenced by a multitude of factors that are crucial for businesses to navigate with expertise. As one of the most commonly used types of glass in construction and manufacturing, understanding the elements affecting its cost is pivotal for making informed purchasing decisions. This article explores the predominant factors impacting the price of 6mm float glass, supported by industry insights and expert opinions.

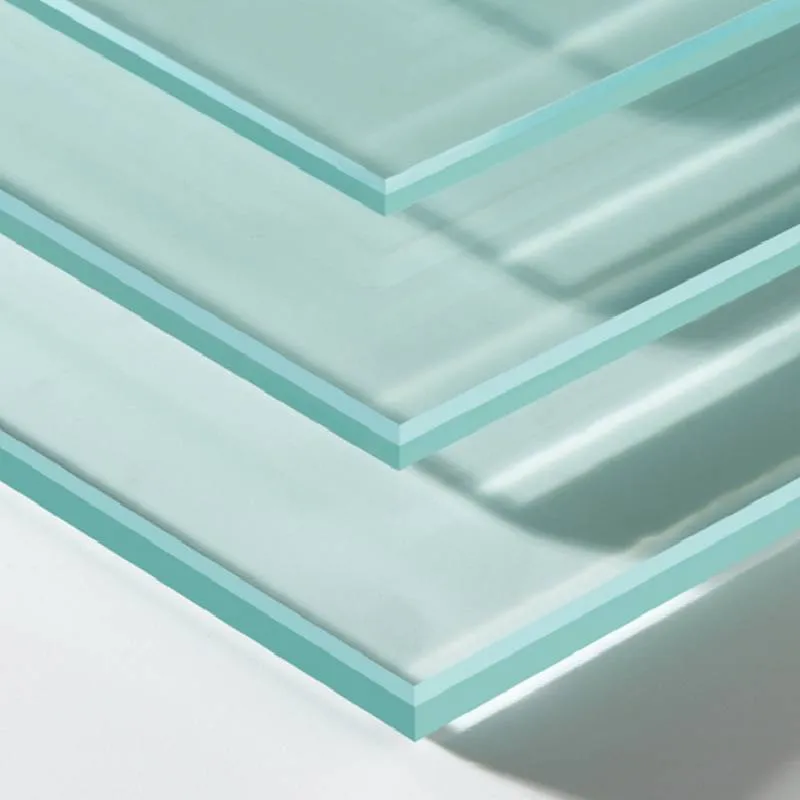

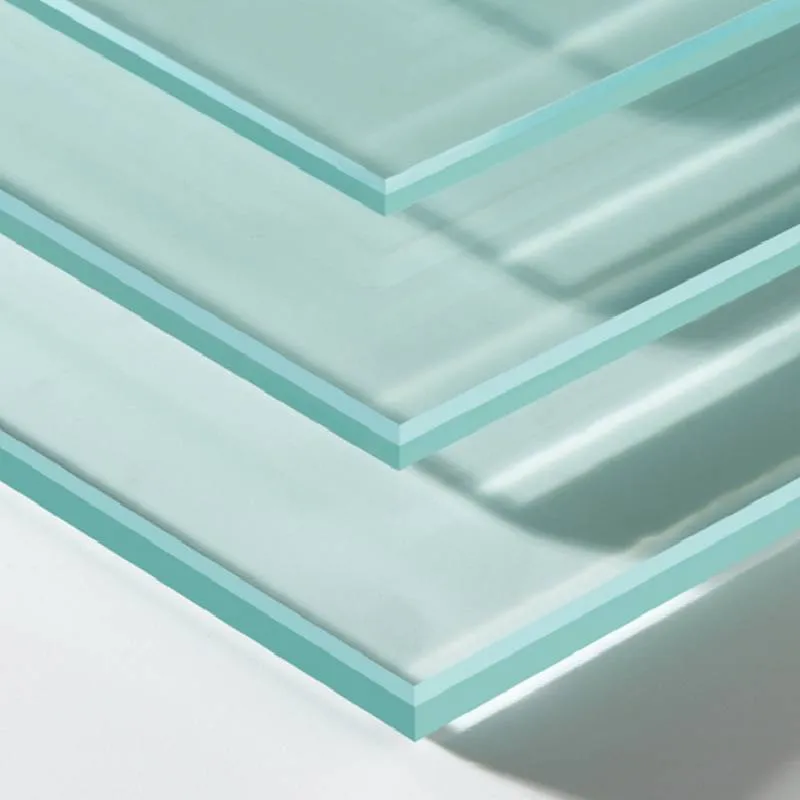

The production process of float glass involves floating molten glass on a bed of molten metal, typically tin, to create a uniform thickness and smooth surfaces. This manufacturing method is used to produce high-quality glass, which is why it continues to be preferred in many architectural and automotive applications. However, fluctuating raw material costs, including silica sand, soda ash, and limestone, significantly influence the market price of float glass. A rise in the cost of these materials inevitably leads to increased production expenses, which suppliers may pass on to consumers.

Moreover, the energy-intensive nature of the float glass production process plays a crucial role in its pricing. Energy costs are a substantial part of the total manufacturing cost due to the high temperatures required for melting and forming the glass. Therefore,

changes in global energy prices can directly impact float glass prices. This is why tracking trends in oil, gas, and electricity markets can offer valuable insights into forthcoming price adjustments in the glass industry.

Transportation and logistics also affect the pricing of 6mm float glass. Given the fragile nature of glass, specialized handling and shipping processes are necessary to prevent damage during transit. Shipping costs can vary significantly, depending on factors such as fuel prices, geographic location, and trade regulations. Consequently, fluctuations in transportation expenses can either increase or decrease the overall cost of acquiring float glass.

Demand and supply dynamics within the glass industry can further cause price volatility. The construction boom in various regions may lead to a surge in demand for 6mm float glass, exerting upward price pressure amidst limited supply. Similarly, during economic slowdowns, reduced demand can result in inventory surpluses and price reductions as suppliers seek to offload excess stock.

6mm float glass price

Technological advancements and innovations in glass manufacturing, while often leading to superior products, can also alter cost structures. Enhanced production techniques that increase efficiency and reduce waste may lower costs over time. However, the initial investment in new technology and equipment can be substantial, potentially driving up prices in the short term until economies of scale are achieved.

Environmental regulations and sustainability initiatives are also increasingly impacting the float glass market. Compliance with stringent environmental standards can increase operational costs for manufacturers, which might be reflected in the product's price. On the other hand, eco-conscious consumers are sometimes willing to pay a premium for sustainable products, which can balance out these additional expenses.

To mitigate price risks, companies often establish long-term contracts with suppliers, securing more predictable pricing over a stipulated period and safeguarding against sudden market fluctuations. However, businesses should remain informed about industry trends and maintain flexibility to adapt to changes swiftly.

In summary, the price of 6mm float glass is influenced by a confluence of factors including raw material costs, energy prices, transportation expenses, supply-demand dynamics, technological innovations, and regulatory compliance. Expertise in these areas along with reliable industry intelligence can provide a strategic advantage for businesses reliant on float glass, ensuring they make cost-effective decisions aligned with their operational goals and market conditions. By maintaining open lines of communication with suppliers and staying current on market trends, companies can better manage and anticipate future pricing changes, safeguarding their budget and ensuring steady supplies of this essential material.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu