The Float Glass Sharpening System Revolutionizing Glass Processing

The float glass manufacturing process is one of the most significant advancements in the glass industry, offering products with exceptional clarity and smoothness. However, achieving the desired sharpness and precision in glass edges requires advanced technology and skilled craftsmanship. This is where the float glass sharpening system comes into play, providing an innovative solution that enhances the finishing touches of glass products.

At its core, the float glass sharpening system is designed to refine the edges of glass sheets, ensuring they are not only aesthetically pleasing but also safe to handle. This system employs various techniques, including mechanical grinding, water jet cutting, and laser technology, to achieve precise edge profiles that meet stringent industry standards. The importance of sharp, polished edges cannot be overstated, as they contribute to both the safety and performance of glass in various applications, from architectural installations to automotive glazing.

One of the standout features of modern float glass sharpening systems is their ability to integrate automation and advanced control technologies. Automated systems can monitor the sharpening process in real-time, making adjustments to ensure consistency and quality. This precision helps manufacturers reduce waste and increase efficiency, ultimately lowering production costs. With the growing demand for high-quality glass products, the implementation of such advanced systems can provide a competitive edge in the market.

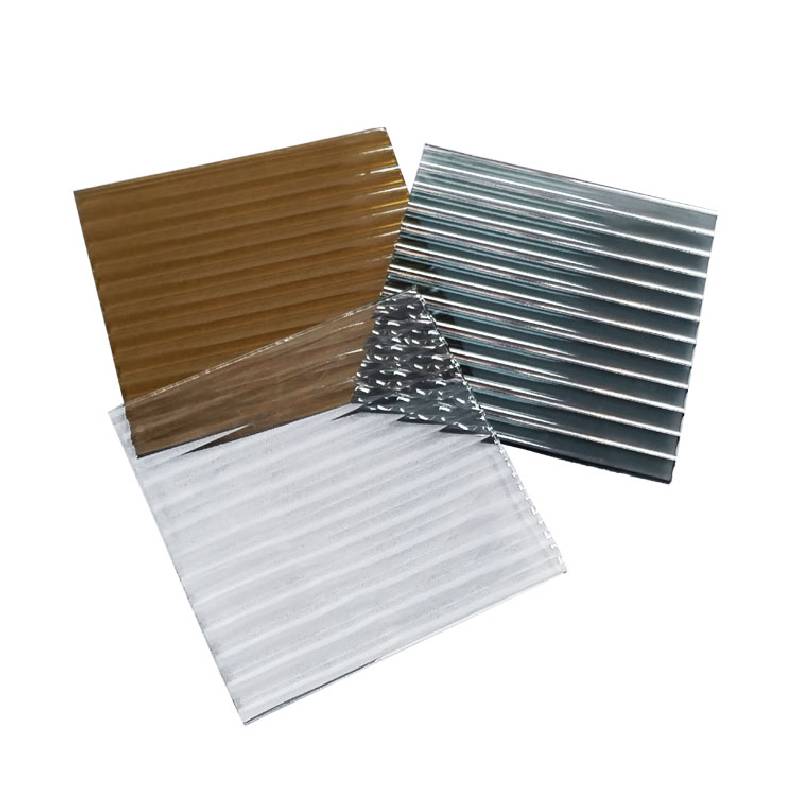

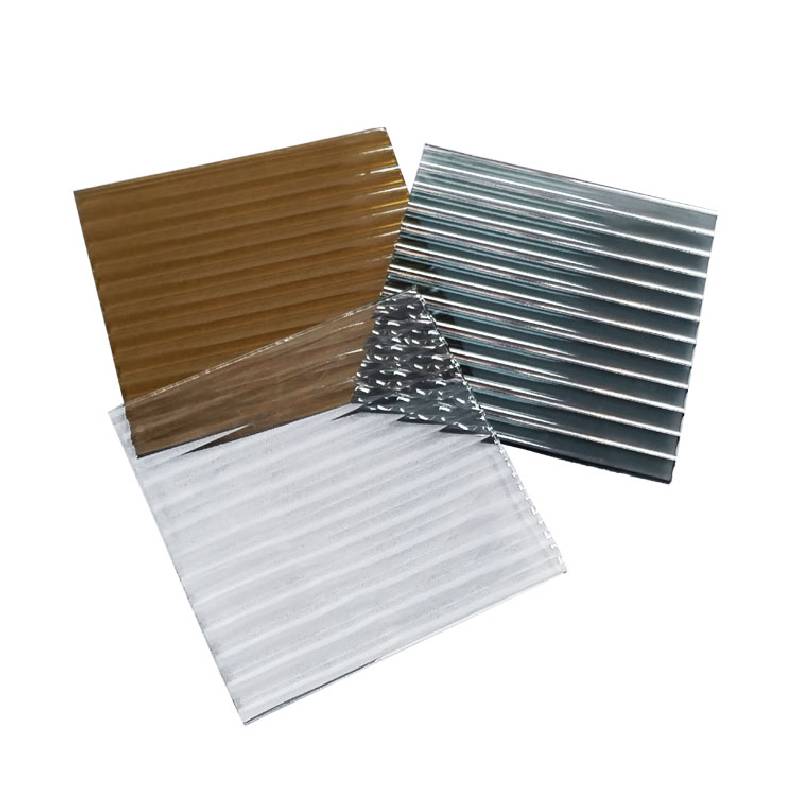

float glass sharpening system

Additionally, environmental considerations play a critical role in the design of float glass sharpening systems. Many contemporary systems are engineered to minimize waste and energy consumption, utilizing water recycling processes and efficient power management. These eco-friendly features align with global sustainability goals, allowing manufacturers to produce high-quality glass while reducing their environmental footprint.

Moreover, the versatility of the float glass sharpening system allows it to accommodate various glass types and thicknesses. Whether dealing with tempered glass, laminated glass, or specialty coatings, the system can be tailored to meet specific requirements. This flexibility is vital for manufacturers who serve multiple markets and need to adapt to changing demands without compromising quality.

In conclusion, the float glass sharpening system represents a significant leap forward in glass processing technology. By enhancing edge precision and incorporating automation, these systems not only improve manufacturing efficiency but also align with the industry's evolving environmental standards. As the demand for sophisticated glass products continues to rise, the float glass sharpening system will undoubtedly play a pivotal role in shaping the future of glass manufacturing, ensuring that products are not only visually striking but also safe and reliable for various applications. With ongoing advancements in technology, the potential for further improvements in this field is limitless, promising an exciting future for the glass industry.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu