Float Glass Manufacturing Plants An Overview

Float glass manufacturing is a pivotal process in the glass industry, playing a crucial role in producing flat glass for various applications, including windows, mirrors, and glass facades. The float glass process, developed in the mid-20th century, revolutionized glass production by allowing for the creation of high-quality, uniform glass sheets. This article explores the fundamentals of float glass manufacturing, its significance, and the innovations driving its development.

The Float Glass Process

The float glass process involves several key steps that transform raw materials into finished products. Initially, the primary components—silica sand, soda ash, and limestone—are mixed together. These raw materials are then heated in a glass furnace to temperatures exceeding 1,600 degrees Celsius (2,912 degrees Fahrenheit) until they melt into a molten glass.

Once the glass reaches a molten state, it is funneled onto a bed of molten tin in a controlled environment, where it spreads out to form a flat surface. This floating process is critical because it allows the glass to achieve a smooth, uniform thickness without the need for grinding or polishing. The molten glass remains on the tin bath for a specific duration, during which it cools slightly to maintain its flatness. After this stage, the glass is slowly cooled in a lehr, a long, temperature-controlled furnace that ensures the glass cools evenly, preventing internal stress and distortion.

Applications of Float Glass

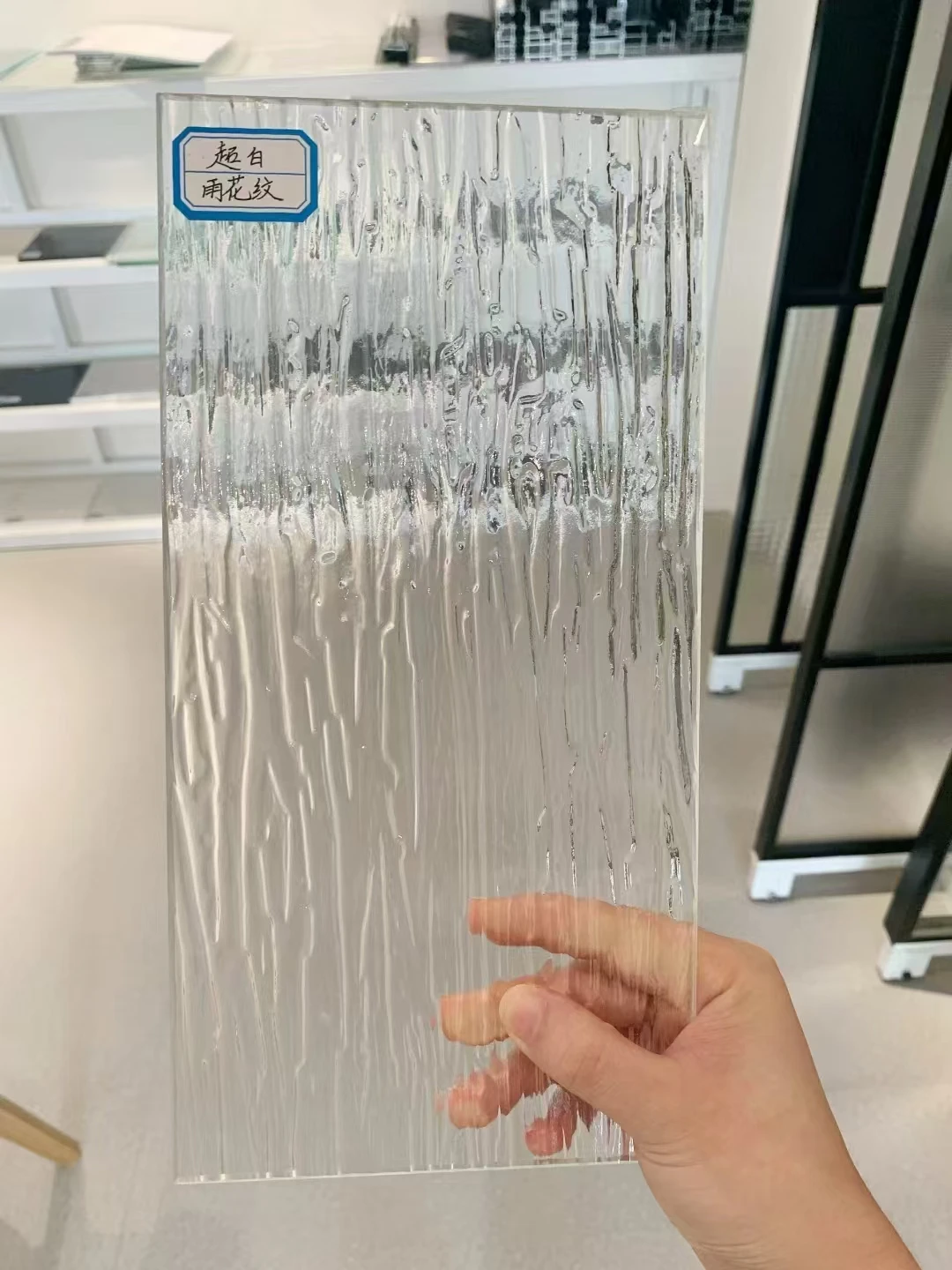

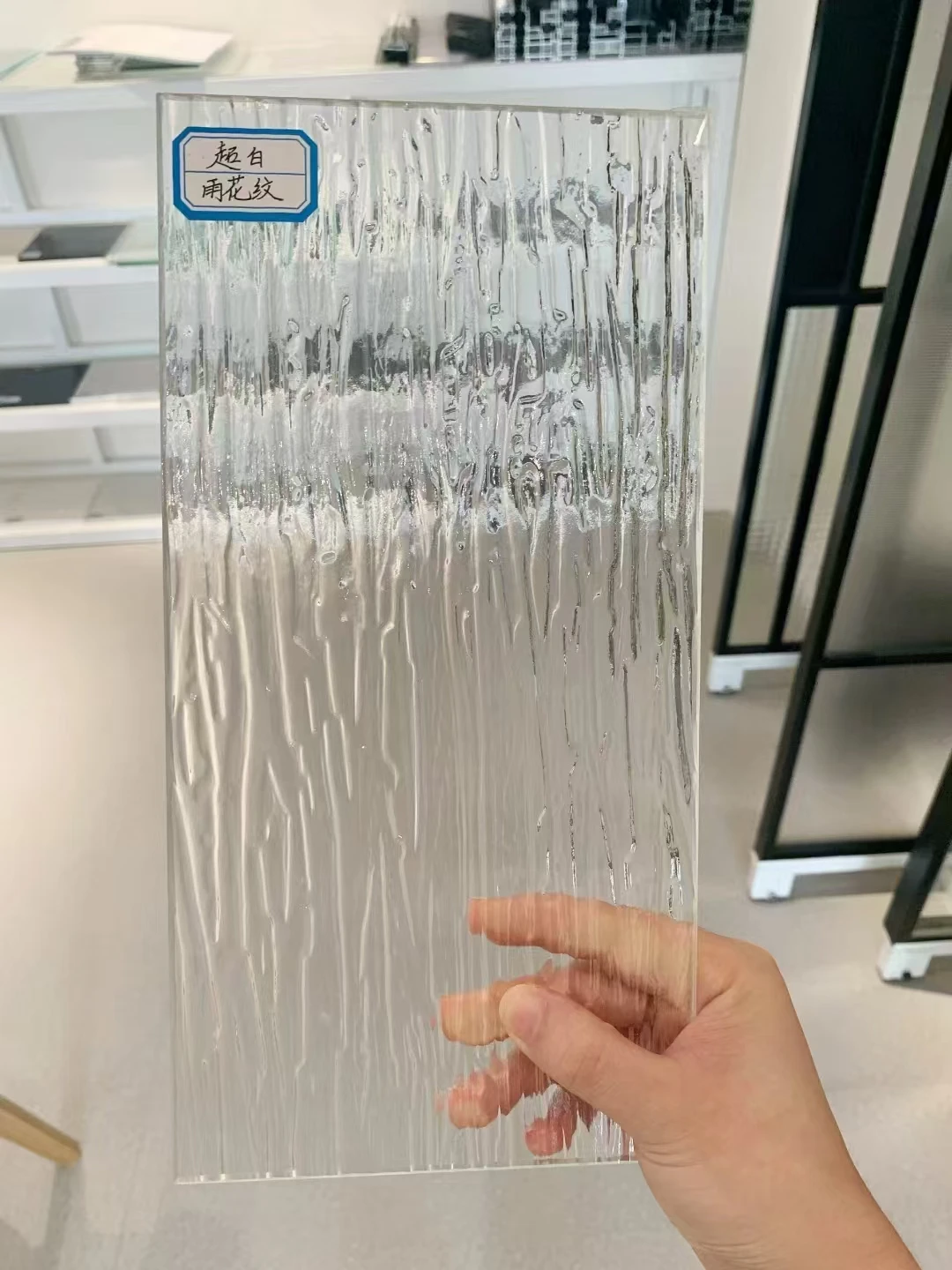

Float glass has a wide array of applications due to its durability, clarity, and versatility. It is primarily used in the construction industry for windows and facades, providing energy efficiency and aesthetic appeal. The reflective properties of float glass make it ideal for mirrors and various decorative applications.

In addition to architectural uses, float glass is an essential material in the automotive sector. Car windows, windshields, and sunroofs are typically made from this glass, as it meets the necessary safety and performance standards. Furthermore, advancements in float glass technology have led to the development of insulated and energy-efficient glass, which enhances thermal performance in buildings, contributing to energy conservation efforts.

float glass manufacturing plant

Environmental Considerations

As with any industrial process, float glass manufacturing has its environmental challenges. The production process is energy-intensive and involves significant greenhouse gas emissions. However, many modern float glass plants are adopting sustainable practices to mitigate their environmental impact. This includes the use of recycled materials, energy-efficient furnaces, and improved waste management practices.

The recycling of glass is particularly noteworthy; cullet (recycled glass) can be used as a raw material in the float glass process, reducing the need for virgin materials and lowering overall energy consumption. This not only benefits the environment but also reduces production costs, making the manufacturing process more economically viable.

Innovations in Float Glass Manufacturing

Technological advancements continue to shape the float glass industry. Innovations such as automated manufacturing systems and real-time monitoring technologies are improving efficiency and product quality. Additionally, the development of smart glass technology, which can change its properties (such as transparency and insulation) in response to environmental conditions, is gaining traction. These innovations are setting the stage for a more dynamic and responsive glass manufacturing sector.

Conclusion

Float glass manufacturing plants are integral to producing high-quality flat glass essential for various industries. As the demand for sustainable and energy-efficient products grows, the float glass industry is evolving through innovations and advancements that prioritize environmental responsibility. By embracing technological advancements and sustainable practices, the future of float glass manufacturing looks promising, contributing to a more efficient and eco-friendly industrial landscape.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu