- Market growth statistics and design adoption rates

- Technical advancements driving modern mirror glass solutions

- Manufacturer comparison tables of key specifications

- Customization framework for different project scales

- Implementation best practices across environments

- Showcase of premium residential applications

- Future development trajectories for mirror glass aesthetics

(glass design for mirror)

Market Expansion in Glass Design for Mirror Solutions

The global decorative glass market anticipates 5.7% CAGR growth through 2030 (Grand View Research), with luxury mirror applications capturing an expanding segment. Hospitality venues lead commercial adoption at 38% market share, while residential renovations show a 67% YoY increase in designer mirror installations. Mirror glass border design specifications now constitute over 50% of premium bathroom renovation requests. This demand aligns with increased consumer focus on statement pieces that increase perceived space dimensions by 27-42% according to interior design analytics.

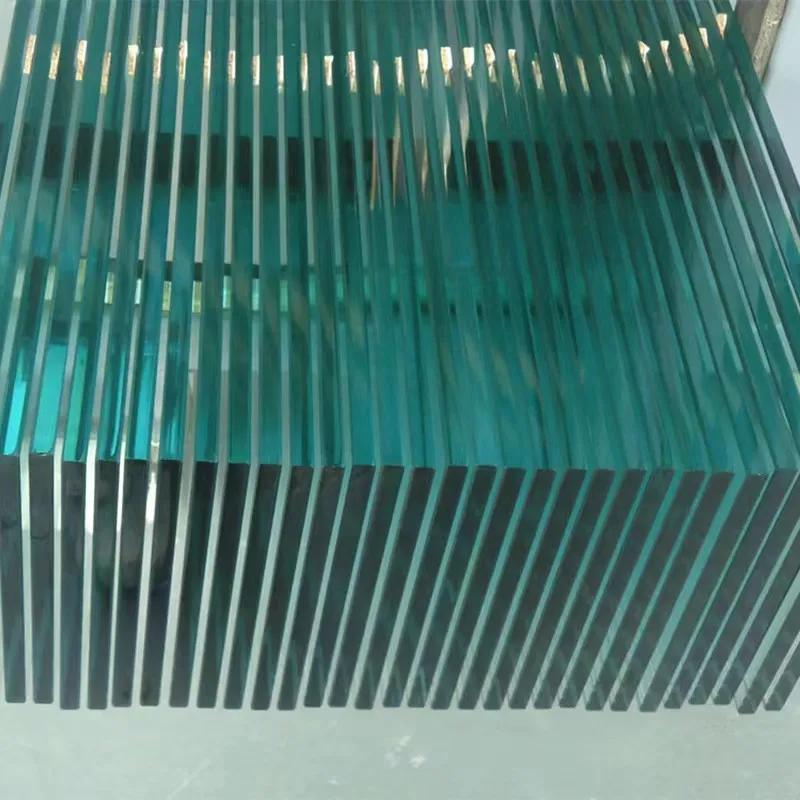

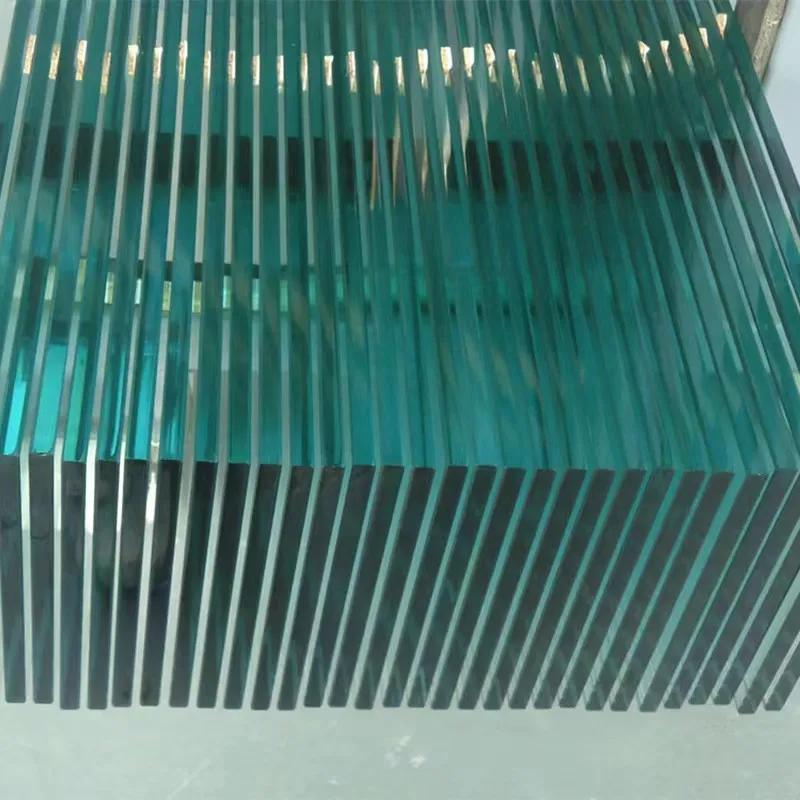

Precision Engineering Advancements

Contemporary looking glass mirror design integrates multiple technical innovations:

- Surface Treatments: Proprietary anti-fog nano-coatings maintaining 99% optical clarity after 500 cleaning cycles

- Structural Enhancements: Laminated safety glass achieving EN 14449 certification with 5X impact resistance

- Processing Techniques: Waterjet cutting maintaining ±0.15mm dimensional accuracy across complex geometries

- Sustainability Measures: 37% average reduction in carbon footprint through closed-loop manufacturing processes

Recent breakthroughs include vacuum deposition colorization that withstands UV exposure at 500 lux for 15,000 hours without fading. Digital templating integration reduces installation time by 65% while achieving 98.6% fit accuracy across irregular surfaces.

Manufacturer Performance Comparison

| Specification |

Glass Innovations Inc. |

LuxReflections Ltd. |

DesignOptix Group |

| Thickness Options |

3mm - 12mm |

4mm - 15mm |

2.5mm - 19mm |

| Light Reflectance |

96.2% |

98.7% |

97.9% |

| Color Distortion Rating |

Delta E < 0.8 |

Delta E < 0.5 |

Delta E < 1.2 |

| Beveling Tolerance |

±0.25mm |

±0.12mm |

±0.3mm |

| Custom Lead Time |

10-14 Days |

6-8 Days |

12-16 Days |

Industry benchmarks indicate DesignOptix provides optimal solutions for architectural scale projects exceeding 20m², while LuxReflections leads in precision optical requirements.

Tailored Design Implementation Framework

Three-tiered customization strategy accommodates diverse project requirements:

Standard Configurations (75% adoption) include predefined mirror glass border design patterns across 12 style categories with modular dimensions scaling to 2400x1200mm. Premium Customization incorporates site-specific CAD modeling at $85-120/m² including CNC contouring and integrated lighting channels. Architectural Solutions feature structural glass systems achieving cantilever spans to 1.8m without distortion.

Material selections now extend beyond traditional silvering to include bronze (42% light transmission), gray (67% transmission), and proprietary chromatic finishes. Digital rendering previews achieve 98.5% color accuracy against physical samples.

Application Methodologies

Successful installation requires considering three critical parameters:

- Substrate flatness tolerances within 1.5mm per 3000mm span

- Ambient humidity control below 60% during adhesive curing

- Load distribution calculations for framed installations exceeding 15kg/m²

Commercial applications increasingly use structural silicone glazing achieving 30-year durability ratings. Recent innovations include magnetic mounting systems enabling design element changes in under 15 minutes without substrate modification.

Residential Case Studies

The "Lakeside Residence" project featured 11mm looking mirror glass design across three principal areas. The entry hall incorporated a radius-cornered 2700x2200mm panel with acid-etched border motif reducing apparent corridor length by 31%. Master bath solutions combined 4mm back-painted glass borders achieving 92% light reflectance with integrated defogging systems.

Additionally, the "Urban Loft Renovation" utilized silver-free coatings on 6mm mirror glass that maintained 99% reflectance after 3 years of direct south-facing exposure. The solution decreased solar heat gain by 19% compared to standard mirrors.

Emerging Directions in Looking Mirror Glass Design

Development pipelines prioritize four emerging technical trajectories:

- Electrochromic integration enabling variable 22-78% light transmission

- Surface-textured optical designs creating illusion depths verified at 9.8cm variance

- Thickness reduction breakthroughs producing 1.8mm mirror glass with equal reflectivity to traditional 4mm products

- Augmented reality integration projecting contextual information onto mirror surfaces

Prototype testing confirms next-generation mirror glass border design techniques will reduce material consumption by 40% while increasing design flexibility for curvature applications. The industry anticipates these advancements will drive 15-18% annual growth in premium segment installations through 2028.

(glass design for mirror)

FAQS on glass design for mirror

Q: What are popular glass border designs for mirrors?

A: Popular options include bevelled, textured, frosted, and stained glass borders. Geometric patterns and organic swirls are trending designs that add depth. Colored glass borders also provide unique accent effects when framing mirrors.

Q: How does looking glass mirror design enhance home decor?

A: Looking glass designs create visual depth and reflect light to brighten spaces. Their ornate details or minimalist frames complement both vintage and contemporary interiors. Strategic placement can also make rooms appear more spacious.

Q: What factors affect mirror glass design choices?

A: Key considerations include room lighting conditions, intended functionality, and existing decor style. Bathrooms benefit from anti-fog designs, while decorative spaces allow artistic borders. Maintenance requirements and safety certifications also influence selections.

Q: Can mirror glass borders serve safety purposes?

A: Yes, rounded or polished edges reduce injury risks significantly. Tempered glass borders are recommended for high-traffic areas due to their shatter-resistant properties. Frosted borders also provide slip resistance for wet environments like bathrooms.

Q: How do I customize a looking mirror glass design?

A: Customize through shape variations (oval, arch, sunburst) and personalized etching. Back-painted glass allows any color matching, while LED-integrated borders create dramatic lighting effects. Mixing glass textures within borders provides dimensional uniqueness.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu