The Art and Science of Sheet Glass Manufacturing

In the modern world, glass is a ubiquitous material used in various applications ranging from architecture to automotive industries. One specific type of glass that plays an integral role in these sectors is sheet glass. The process of manufacturing sheet glass combines traditional craftsmanship with advanced technology, yielding a product that is both functional and aesthetically pleasing.

Sheet glass, characterized by its flat and smooth surface, is produced using several methods, with float glass being the most prominent. The float glass process, invented by Sir Alastair Pilkington in the 1950s, revolutionized the glass industry by providing uniform thickness and clarity. This method involves melting raw materials such as silica sand, soda ash, and limestone at very high temperatures to create molten glass. The molten glass is then poured onto a bed of molten tin, where it naturally spreads out to form a smooth, flat surface. The glass floats on the tin, allowing it to maintain a uniform thickness while eliminating surface imperfections.

The Art and Science of Sheet Glass Manufacturing

Once the sheets are cut, they undergo a series of treatments to enhance their durability and aesthetic qualities. Treatments such as annealing, which involves gradually cooling the glass, help to relieve internal stresses and improve strength. Additionally, chemical treatments can be applied to create tempered glass, which is significantly stronger and shatter-resistant compared to standard glass. This is particularly important for applications where safety is a concern, such as in the construction of buildings and in the automotive industry.

sheet glass manufacturing

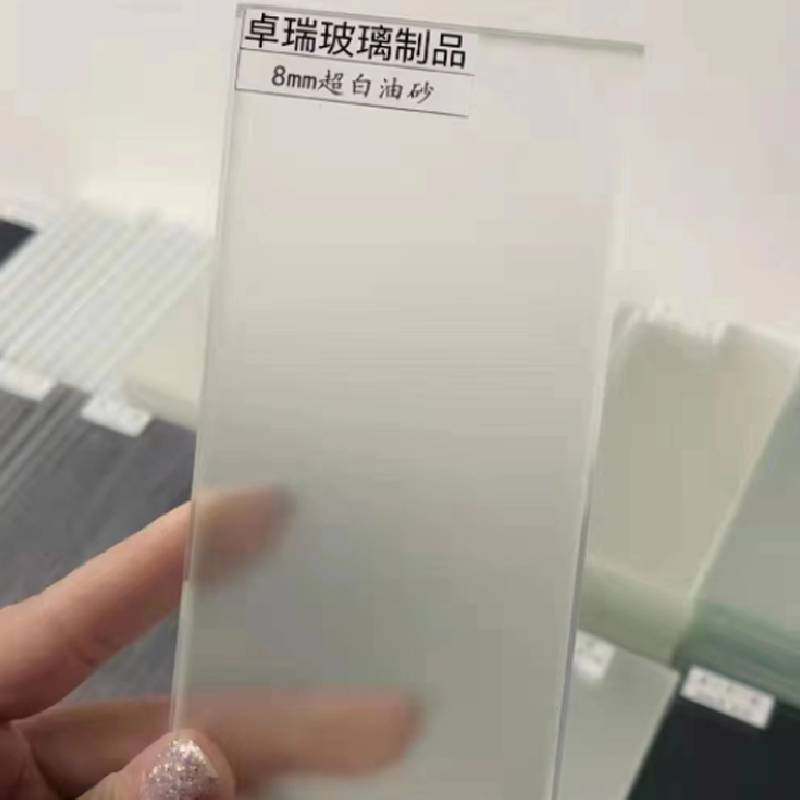

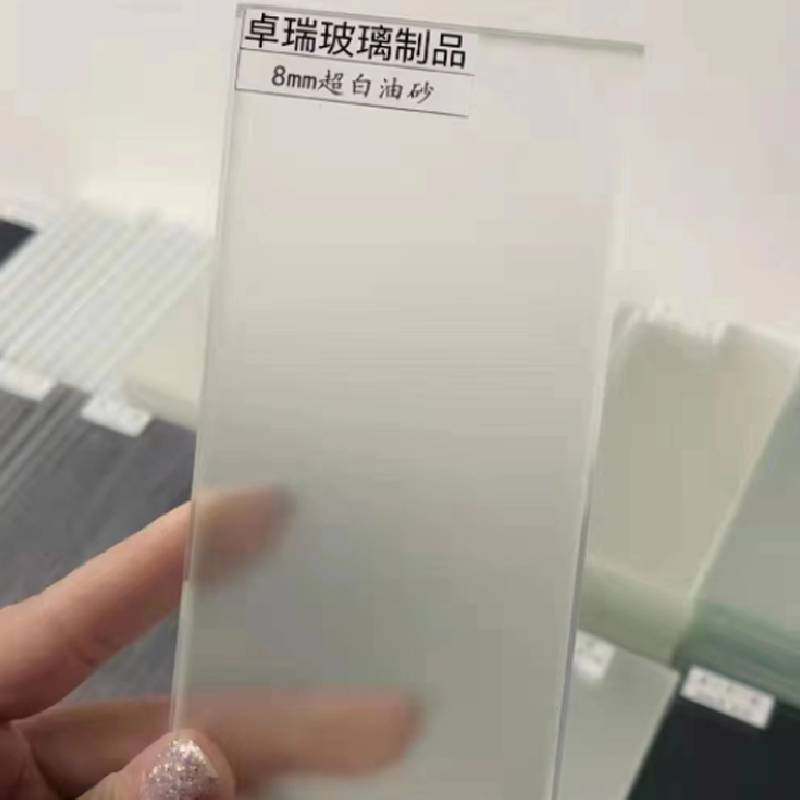

The versatility of sheet glass is one of its most appealing features. It can be customized with various coatings and finishes, allowing it to serve multiple purposes. For instance, low-emissivity (Low-E) coatings can improve energy efficiency by reflecting heat while allowing natural light to pass through. This is especially beneficial in the design of energy-efficient buildings. Moreover, decorative finishes, such as frosted or patterned glass, can enhance aesthetic appeal while still providing functionality.

Environmentally, the sheet glass manufacturing industry is making strides towards sustainability. The recycling of glass has become an integral part of the production process. Recycled glass can be used as a raw material, reducing the need for virgin materials and minimizing waste. Furthermore, advancements in energy-efficient technologies are helping manufacturers reduce their carbon footprint during production. The industry continues to explore innovative methods to enhance sustainability, from using renewable energy sources in manufacturing facilities to improving the recyclability of finished products.

In recent years, there has also been a growing trend towards smart glass technology. Smart glass uses electrochromic or photochromic materials that can change their opacity or color in response to electric currents or light exposure. This innovation has opened new avenues for architectural design and energy management, allowing buildings to adapt to environmental conditions dynamically.

In conclusion, the manufacturing of sheet glass is a remarkable blend of art and science. From the precision of its production methods to the innovative applications of the final product, the industry continues to evolve and adapt to meet modern demands. As technology advances and sustainability becomes increasingly important, sheet glass is poised to remain a vital material in both everyday life and specialized applications. Its role in enhancing energy efficiency, safety, and aesthetic value makes sheet glass a cornerstone of contemporary manufacturing and design. The future of sheet glass is bright, reflecting the progress of an industry dedicated to quality, innovation, and sustainability.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu