The Process of Making Tempered Glass

Tempered glass, also known as toughened glass, is a type of safety glass that has been treated by thermal or chemical processes to increase its strength compared to standard glass. The production of tempered glass is a meticulously controlled process that involves several key steps, each critical to ensuring the final product's durability and safety.

Step 1 Raw Material Selection

The process begins with the selection of high-quality raw materials. The primary ingredient is silica sand, which is combined with other materials such as soda ash and limestone. The purity of these materials is vital; even slight impurities can affect the glass's strength. These materials are carefully measured and mixed to create a uniform batch.

Step 2 Melting

Once the materials are prepared, they are fed into a furnace where they are heated to extremely high temperatures, typically around 1,700 degrees Fahrenheit (927 degrees Celsius). During this melting phase, the raw materials transform into molten glass. The furnace must maintain a consistent temperature to ensure that the glass melts evenly, which is crucial for the subsequent steps.

Step 3 Forming

After the glass has melted, it is shaped into the desired form. This can be achieved through various techniques, including blowing, pressing, or floating the glass on molten tin to create flat sheets. The chosen method depends on the intended application of the glass, whether it be for windows, doors, or structural components.

During the forming stage, it is essential to avoid any defects such as bubbles or uneven thickness, as these can compromise the strength of the tempered glass

.

Step 4 Annealing

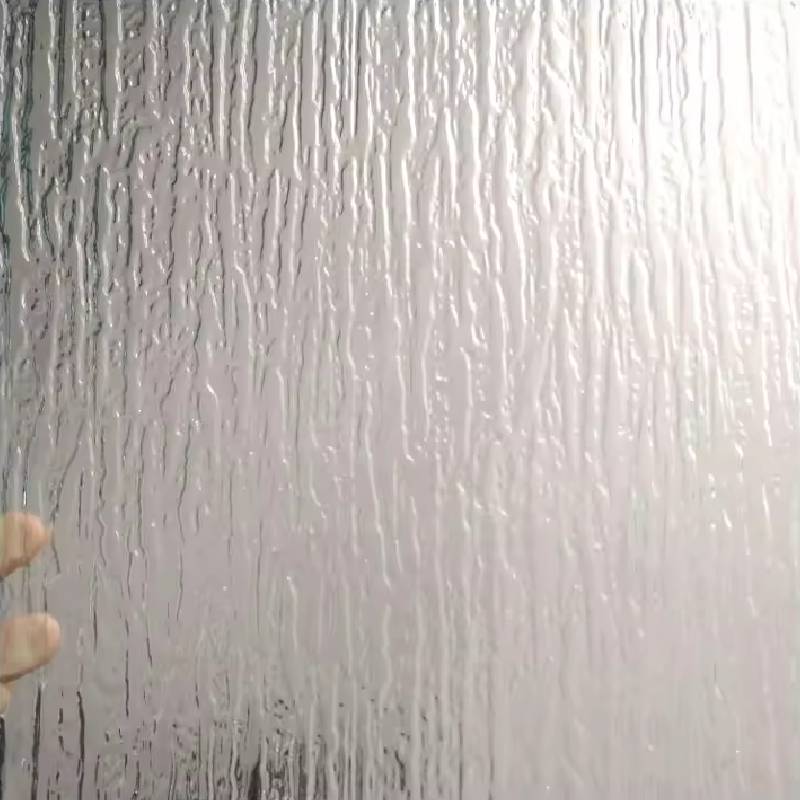

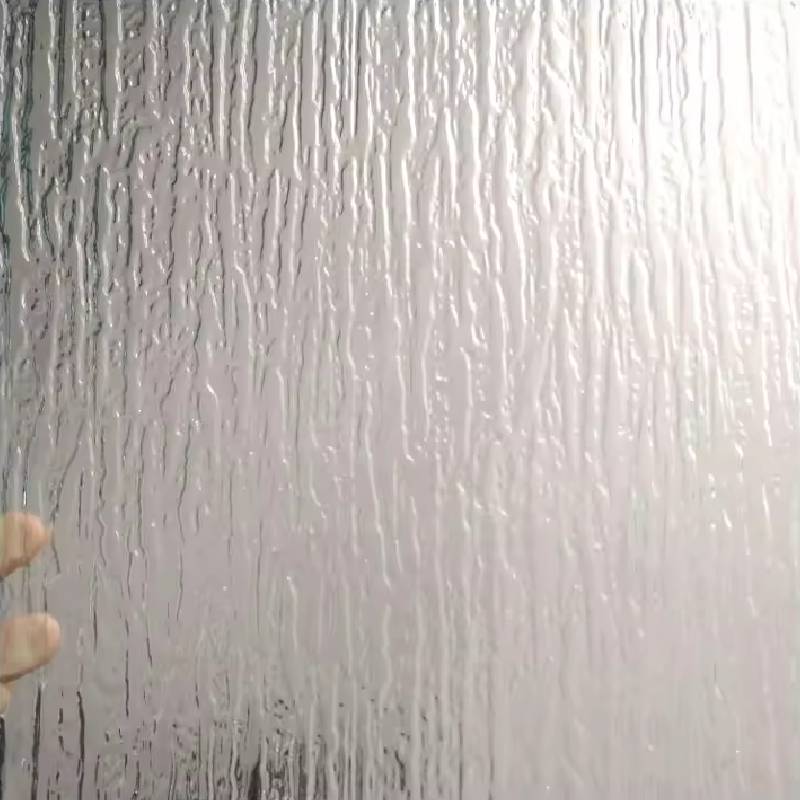

process of making tempered glass

Following the forming process, the glass must undergo annealing. This is a crucial step where the glass is slowly cooled in a controlled environment. Annealing helps relieve internal stresses that may have developed during the melting and shaping processes. This controlled cooling is often performed in a lehr, which is an oven designed for this purpose, and it can take several hours to days.

Step 5 Tempering

The tempering process is where the glass is treated to enhance its strength. The formed glass sheets are reheated to approximately 1,300 degrees Fahrenheit (704 degrees Celsius) and then rapidly cooled using a process called quenching. This rapid cooling creates a significant difference in thermal stress across the glass. The outer surfaces cool and harden quickly, while the inner parts remain warmer for longer. This results in a compressive layer on the surface that increases the glass's resistance to impacts and temperature changes.

Step 6 Inspection and Quality Control

Once tempered, the glass undergoes rigorous inspection and quality control. It is tested for strength, clarity, and uniformity. Any defects, such as cracks or discolorations, must be identified and addressed. Quality control is critical as tempered glass is often used in situations where safety is paramount, such as in automotive and architectural applications.

Step 7 Cutting and Finishing

Finally, once the tempered glass has passed inspection, it is cut to the required sizes and may undergo additional finishing processes, such as polishing or edge treatment. These steps ensure that the glass is ready for installation in its intended application.

Conclusion

The process of making tempered glass is a complex and precise operation that combines materials science with advanced manufacturing techniques. The result is a product that offers enhanced strength, safety, and versatility, making tempered glass an essential material in modern construction and design. By understanding the intricate steps involved in its production, one can appreciate the engineering marvel that tempered glass represents.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu