The Cost of 10mm Toughened Glass An In-Depth Analysis

Toughened glass, also known as tempered glass, is an increasingly popular choice in the construction and interior design industries due to its safety and durability features. When considering the installation of 10mm toughened glass, understanding its cost implications is crucial for both suppliers and consumers. This article explores the various factors that influence the pricing of 10mm toughened glass, including material costs, manufacturing processes, market demand, and application suitability.

Understanding Toughened Glass

Before delving into costs, it's essential to define what toughened glass is. Toughened glass is produced through a thermal or chemical treatment process that increases its strength and thermal resistance compared to regular glass. The standard thickness for toughened glass ranges from 4mm to 19mm, and the 10mm variant strikes a balance between strength and weight, making it a popular choice for a variety of applications, including shower screens, balustrades, and glass doors.

Factors Affecting the Cost

1. Material Costs

The primary raw material used to manufacture toughened glass is silica sand, which is abundant and relatively inexpensive. However, the cost of additional materials, such as various additives and the glass molding processes, can influence overall pricing. Prices for raw materials can fluctuate due to market conditions, which may affect the final cost of the glass.

2. Manufacturing Process

The production of toughened glass involves specialized techniques that require advanced technology and equipment. The glass must be heated to around 620 degrees Celsius and then rapidly cooled to achieve the desired strength. This process is energy-intensive and requires skilled labor, contributing to higher manufacturing costs. Depending on the scale of production and technological investment, costs may vary significantly.

3. Market Demand

Like any product, the costs of 10mm toughened glass are influenced by market demands. In regions experiencing a construction boom or high demand for renovation projects, the price of toughened glass may rise. Conversely, economic downturns can lead to reduced demand, consequently lowering prices. Seasonal factors may also impact demand, with certain times of the year being busier for construction and renovations.

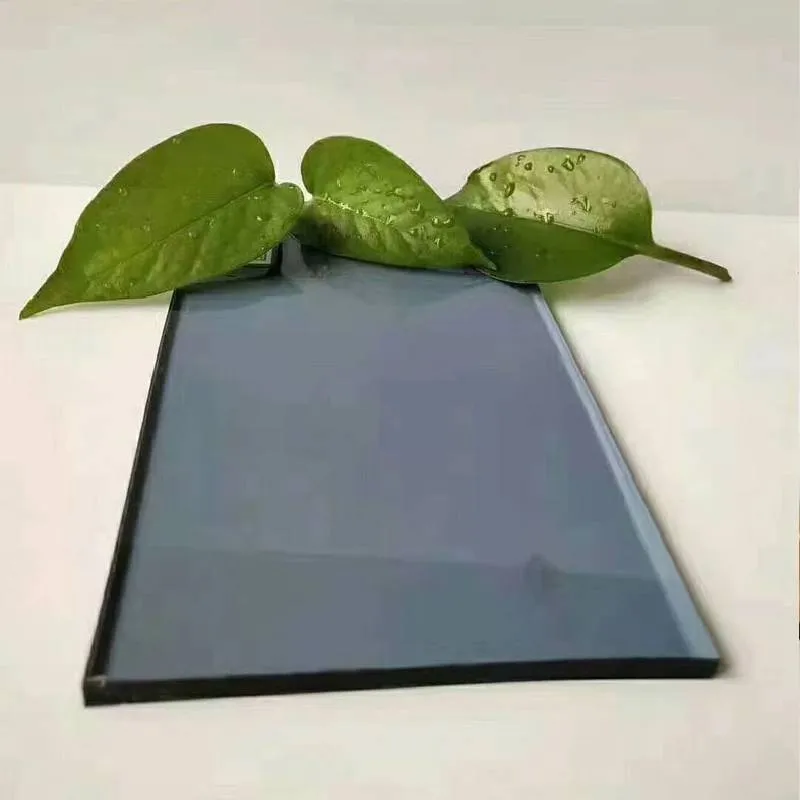

cost of 10mm toughened glass

4. Application-Specific Pricing

The application of the 10mm toughened glass significantly impacts its price. For instance, tempered glass used in high-traffic commercial settings or safety applications such as glass facades or skylights may be priced higher due to the need for enhanced specifications and certifications. In contrast, applications like interior partitions may have lower standards, leading to more competitive pricing.

5. Transportation and Installation

Transporting large sheets of glass can be both challenging and costly. The fragility of glass means that specialized equipment is often needed for transportation, which can add to the overall expense. Furthermore, the cost of installation should not be overlooked. Employing skilled glaziers ensures proper handling and fitting, but comes at an additional price.

6. Customization and Finishing

Another determinant of the cost is the level of customization required. High-quality finishes, such as frosted glass or printed designs, may increase the overall price of 10mm toughened glass. Custom-cut sizes or unique edge treatments also contribute to higher labor and material expenses.

Cost Overview

As of the latest data, the cost of 10mm toughened glass typically ranges from $30 to $70 per square meter, depending on the factors mentioned above. For larger projects, bulk purchasing may result in discounts, potentially lowering costs. Additionally, local market conditions and the availability of materials play a significant role in determining prices.

Conclusion

Understanding the various factors that contribute to the cost of 10mm toughened glass is essential for making informed purchasing decisions. From raw material prices to manufacturing processes, market demand, and the specific application, each element plays a key role in the final cost. When planning a project that involves toughened glass, taking these factors into accountwill help budget accurately and choose the best possible options for safety, durability, and aesthetics. Being well-informed can lead to better choices that ensure both functionality and economic viability in architectural and design pursuits.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu