Understanding Reflective Glass: A Core Component in Modern Architecture

In contemporary architectural design and building efficiency, reflective glass stands out as a pivotal material, offering a synergistic blend of aesthetic appeal, superior energy performance, and enhanced occupant comfort. This specialized glass is engineered with a metallic coating that reflects a significant portion of incident solar radiation, thereby reducing solar heat gain within a building. Its unique properties are particularly beneficial in environments requiring stringent climate control and visual privacy, making it indispensable for high-rise commercial buildings, institutional structures, and even residential applications where solar management is critical. The technology behind reflective glass has evolved considerably, moving beyond mere surface aesthetics to deliver measurable improvements in building energy consumption and internal environmental quality. As global imperatives push for greener buildings and reduced carbon footprints, the demand for advanced glazing solutions like this continues to escalate. Understanding the nuanced technical specifications, manufacturing intricacies, and diverse application potentials of reflective glass is essential for architects, developers, and engineers committed to sustainable and high-performance building envelopes. This comprehensive guide delves into the specifics, offering insights into its composition, production, performance metrics, and strategic deployment in various sectors, showcasing why it remains a cornerstone of modern, energy-efficient construction.

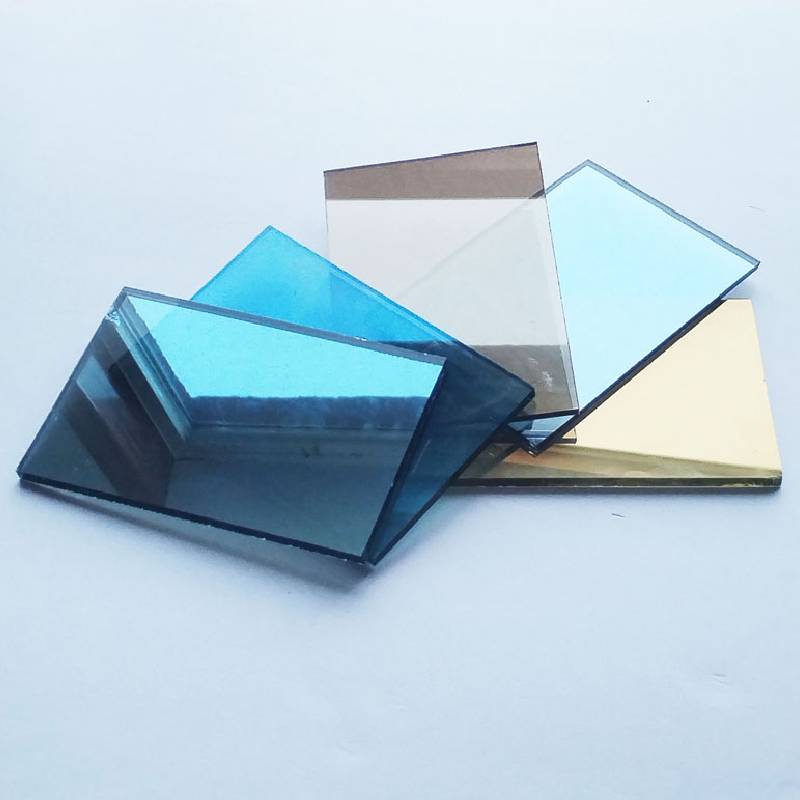

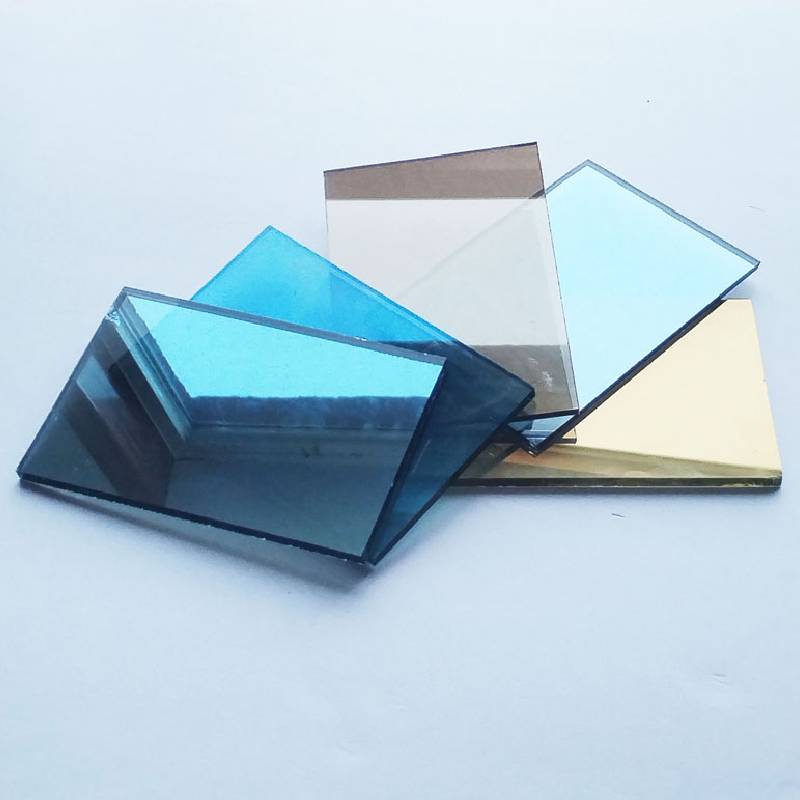

The market for reflective glass is characterized by a strong drive towards innovation, with manufacturers continually developing new coatings and substrate combinations to meet evolving demands for transparency, color variation, and thermal performance. Products like 5mm reflective glass are particularly popular due to their balance of strength and versatility, finding applications in various contexts from curtain walls to skylights. The aesthetic versatility is also a significant factor, with options ranging from subtle tints to vibrant hues, including sophisticated black reflective glass, elegant blue reflective glass, and classic bronze reflective glass. Each color and thickness offers distinct visual and performance characteristics, allowing architects to tailor solutions precisely to project requirements. For instance, black reflective glass window designs often deliver a sleek, monolithic appearance, while blue reflective glass window installations can evoke a more contemporary and expansive feel. The 5mm reflective glass price point typically makes it a cost-effective choice for large-scale projects, balancing performance with budgetary considerations. These diverse offerings underscore the adaptability of reflective glass, ensuring its continued relevance in the dynamic world of building materials.

The Science and Manufacturing Precision of Reflective Glass

Decoding the Core Technology: How Reflective Glass Works

At its heart, the performance of reflective glass hinges on advanced coating technologies that manipulate the solar spectrum. Unlike standard clear glass, which allows most solar energy to pass through, reflective glass features a microscopically thin metallic or metallic oxide layer applied to one surface. This layer acts as a selective filter, effectively reflecting a significant portion of incoming solar radiation, particularly in the infrared and ultraviolet ranges, while still permitting visible light to transmit. This mechanism results in a lower Solar Heat Gain Coefficient (SHGC), meaning less solar energy enters the building, significantly reducing the load on HVAC systems. The degree of reflection and transmission can be precisely controlled by adjusting the composition and thickness of the metallic coating. For instance, a denser metallic coating will yield a higher reflectance and a lower SHGC, suitable for hot climates or facades facing intense sun exposure. Conversely, a lighter coating might be preferred where a balance between solar control and natural daylighting is desired. The coatings are typically applied using sophisticated vacuum deposition techniques, such as magnetron sputtering (MSVD), ensuring exceptional uniformity and durability. This technical sophistication is what distinguishes high-performance reflective glass from ordinary tinted glass, providing quantifiable energy savings and enhanced occupant comfort through reduced glare and heat build-up. The specific properties of 5mm reflective glass, for example, are optimized for general architectural applications, striking an ideal balance between thermal performance and structural integrity, making it a highly versatile solution for various building types and climates. The optical properties, including visible light transmittance (VLT), visible light reflectance (VLR), and UV transmittance, are meticulously measured and specified to meet diverse design and energy performance criteria.

Precision Manufacturing: From Raw Materials to Finished Panels

The manufacturing of reflective glass is a multi-stage process demanding meticulous control and adherence to stringent quality standards. It typically begins with the production of high-quality float glass, which serves as the substrate. Raw materials such as silica sand, soda ash, limestone, and dolomite are melted in a furnace at extremely high temperatures (around 1500°C) and then poured onto a bed of molten tin. This "float" process creates a perfectly flat, uniform sheet of glass with parallel surfaces, essential for optical clarity and coating consistency. Once the base glass is formed and cooled, the specialized reflective coating is applied. There are primarily two methods for applying these coatings: Pyrolytic (Hard Coat) and Sputter (Soft Coat). The pyrolytic process involves applying the metallic oxide coating to the glass ribbon while it is still hot, fusing it to the glass surface. This results in a durable, hard coating that is scratch-resistant and can be used in single glazing. Sputter coating, on the other hand, involves depositing multiple layers of metallic materials in a vacuum chamber at room temperature. This "soft coat" offers superior thermal performance and a wider range of aesthetic options, including various tints like black reflective glass and blue reflective glass. However, soft coatings are more delicate and typically require protection within an insulating glass unit (IGU). Post-coating, the glass undergoes rigorous quality control, including optical inspection, thickness measurement, and spectral analysis to verify its reflective properties. Products like 5mm reflective glass dark green reflective glass undergo specific color calibration. Adherence to international standards such as ISO 9001 for quality management, ASTM C1048 for heat-treated flat glass, and EN 1096 for coated glass ensures the final product meets the highest benchmarks for performance and safety. This meticulous process ensures that each sheet of reflective glass delivers consistent performance and longevity, typically exceeding 20 years in standard applications, contingent on proper installation and maintenance. The precision in manufacturing allows for tailored solutions, offering varying degrees of reflection, transmission, and aesthetic profiles to suit diverse architectural visions and environmental challenges.

Technical Parameters and Performance Metrics

The efficacy of reflective glass is quantifiable through a series of key technical parameters that provide architects, engineers, and developers with critical data for performance specification and comparison. Understanding these metrics is paramount for selecting the optimal glazing solution for any given project. The most significant parameters include: Solar Heat Gain Coefficient (SHGC), which measures the fraction of incident solar radiation admitted through a window, either directly transmitted or absorbed and re-radiated inward; a lower SHGC indicates better solar control. Visible Light Transmittance (VLT), representing the percentage of visible light that passes through the glass; higher VLT values mean more natural daylight. Visible Light Reflectance (VLR), the percentage of visible light reflected by the glass; higher VLR contributes to privacy and a mirrored appearance from the exterior. U-value (or U-factor), which measures the rate of heat transfer through the glass unit due to temperature difference between indoor and outdoor air; a lower U-value signifies better insulation and reduced heat loss or gain. Shading Coefficient (SC), an older metric, is approximately 0.87 times the SHGC, indicating the relative solar heat gain compared to 3mm clear glass. UV Transmittance, the percentage of harmful ultraviolet radiation that passes through the glass; lower values protect interiors from fading. When considering products like 5mm reflective glass, these parameters are crucial in evaluating its suitability for specific climatic conditions and design objectives. For instance, in hot climates, a low SHGC and high VLR are prioritized to minimize heat ingress and glare, whereas in colder climates, a low U-value becomes paramount to retain internal heat. Manufacturers often provide detailed performance data for their entire range, including variations like black reflective glass and blue reflective glass, allowing for precise selection based on project needs and energy efficiency targets. This data-driven approach ensures that investments in reflective glass translate into tangible long-term benefits in terms of energy savings and occupant comfort, validated by industry standards such as NFRC (National Fenestration Rating Council) ratings in North America or relevant EN standards in Europe.

Comparative Performance Table: Reflective Glass Variations

| Parameter |

5mm Clear Reflective Glass (Typical) |

5mm Dark Green Reflective Glass (e.g., product) |

5mm Blue Reflective Glass (Typical) |

5mm Black Reflective Glass (Typical) |

5mm Bronze Reflective Glass (Typical) |

| Visible Light Transmittance (VLT) |

40-50% |

30-38% |

25-35% |

10-20% |

20-30% |

| External Visible Light Reflectance (VLR-ext) |

25-35% |

20-28% |

25-35% |

35-45% |

30-40% |

| Solar Heat Gain Coefficient (SHGC) |

0.35-0.45 |

0.30-0.38 |

0.28-0.35 |

0.18-0.25 |

0.25-0.32 |

| U-value (W/m²K) - Single Glazing |

~5.7 |

~5.7 |

~5.7 |

~5.7 |

~5.7 |

| UV Transmittance |

0.1-0.2 |

<0.1 |

<0.1 |

<0.1 |

<0.1 |

Note: The U-value for single glazing is primarily dependent on glass thickness and not significantly on the reflective coating itself. For improved U-value, reflective glass is often integrated into Insulated Glass Units (IGUs) with inert gas fills and low-emissivity coatings. Values are typical and may vary based on specific manufacturer and coating technology. This table underscores that while all forms of reflective glass excel in solar control, specific tints like black reflective glass offer superior solar heat gain reduction at the expense of visible light, while options like blue reflective glass or bronze reflective glass provide a balance of aesthetic and performance characteristics.

Applications and Advantages of Reflective Glass Solutions

Diverse Application Scenarios Across Industries

The versatility of reflective glass extends its utility across a broad spectrum of industries, making it a preferred choice for architects and developers seeking optimal performance and aesthetic integration. In the Architectural Sector, its primary application is in building facades, curtain walls, and skylights for commercial towers, office complexes, and public institutions. The ability of reflective glass to control solar heat gain is invaluable for reducing cooling loads in large-scale structures, contributing significantly to LEED certification and other green building initiatives. For instance, a major commercial complex in a sun-intensive region might specify 5mm reflective glass dark green reflective glass to achieve maximum solar rejection while offering a distinctive visual appeal. In Residential Applications, particularly for high-end homes and apartments, it provides enhanced privacy and glare reduction, creating more comfortable living spaces. The sleek look of black reflective glass window installations has become a signature element in modern minimalist designs. Beyond conventional building envelopes, reflective glass is also integral to Specialized Industrial Environments. In sectors like petrochemicals or heavy manufacturing, where control rooms or administrative buildings are adjacent to heat-generating processes, reflective glass helps maintain stable indoor temperatures and reduces the need for excessive air conditioning, protecting sensitive equipment and improving worker comfort. While not directly "anti-corrosion" in the chemical sense, its ability to mitigate thermal stress by reflecting radiant heat contributes to the longevity of building materials in such demanding environments. Furthermore, in Transportation Infrastructure, such as bus shelters, train stations, or airport terminals, reflective glass is used to improve passenger comfort by reducing solar heat and glare, while also offering a degree of visual screening. Its durability and aesthetic appeal also make it suitable for interior applications such as partitions and decorative elements, where it can reflect light to create a sense of spaciousness or privacy in commercial interiors. These diverse applications underscore the adaptive nature of reflective glass in meeting complex functional and design requirements.

Key Advantages: Energy Efficiency, Aesthetics, and Comfort

The adoption of reflective glass translates into several tangible benefits for building owners and occupants, making it a sound long-term investment. Energy Efficiency is perhaps its most compelling advantage. By significantly reducing the amount of solar heat gain, reflective glass dramatically lowers cooling costs, especially in regions with high solar exposure. Studies have shown that buildings utilizing high-performance reflective glass can achieve up to 30-40% reduction in HVAC energy consumption compared to those with standard clear glazing. This translates directly to lower operational expenses and a reduced carbon footprint, aligning with global sustainability goals. For example, a project specifically using 5mm reflective glass dark green reflective glass can achieve optimal solar rejection rates while maintaining an appealing aesthetic. Beyond energy savings, Enhanced Occupant Comfort is a critical benefit. The reflective coating minimizes glare, creating a more comfortable visual environment for occupants, especially those working with computer screens. It also reduces "hot spots" near windows, ensuring a more uniform indoor temperature. Furthermore, the UV-blocking properties of reflective glass help protect interior furnishings, artworks, and sensitive equipment from fading and degradation. Aesthetically, reflective glass offers a modern, sophisticated look that can dramatically enhance a building's exterior. The mirrored appearance during daylight hours provides excellent Daytime Privacy, as external observers see their reflection rather than the interior of the building. The wide range of available colors, including black reflective glass, blue reflective glass, and bronze reflective glass, allows for significant design flexibility, enabling architects to create distinctive facades that integrate seamlessly with their urban surroundings. The interplay of light and reflection on a building clad in reflective glass can create dynamic visual effects, making the structure a prominent landmark. These combined advantages underscore the holistic value proposition of reflective glass as a comprehensive solution for modern, high-performance buildings.

Strategic Sourcing: Manufacturer Comparison and Customization

Selecting the Right Partner: Key Considerations for Manufacturers

Choosing the right manufacturer for reflective glass is a critical decision that impacts project timelines, budgets, and the long-term performance of the building. Beyond merely comparing the 5mm reflective glass price, discerning buyers must evaluate several key criteria to ensure a reliable partnership. Firstly, Experience and Reputation are paramount. A manufacturer with a long track record and a portfolio of successful, high-profile projects demonstrates proven capability and reliability. Verify their service years and their presence in the global market. Secondly, Technological Capabilities are crucial. Leading manufacturers invest heavily in state-of-the-art production facilities, utilizing advanced coating technologies like MSVD for superior performance and consistency. This includes the ability to produce a wide range of reflective glass types, from standard clear to specialized black reflective glass or blue reflective glass with precise optical properties. Thirdly, Quality Certifications and Compliance are non-negotiable. Reputable suppliers adhere to international standards such as ISO 9001 (Quality Management Systems), ISO 14001 (Environmental Management Systems), and product-specific standards like ASTM C1048, EN 1096, and ANSI Z97.1 (for safety glazing). These certifications provide independent assurance of product quality and manufacturing processes. Fourthly, assess their Customization and Technical Support capabilities. Can they produce specific tints, thicknesses, or complex shapes required for unique architectural designs? Do they offer comprehensive technical data, CAD details, and engineering support for complex installations? Fifthly, consider their Logistics and Delivery Capabilities. Given the fragility and bulk of glass, efficient and secure packaging, transportation, and timely delivery are vital to keep projects on schedule. Lastly, After-Sales Support and Warranty are indicators of a manufacturer's commitment to their product. A robust warranty program and responsive customer service for any potential issues demonstrate trustworthiness. Engaging with manufacturers who actively partner with their clients, offering expert advice and collaborative problem-solving, ensures a smoother and more successful project execution. By meticulously vetting these aspects, stakeholders can secure high-quality reflective glass solutions that meet both performance and budgetary requirements, aligning with the principles of Authoritativeness and Trustworthiness.

Tailored Solutions: Customization and Project-Specific Design

Modern architecture often demands unique and highly customized glazing solutions, and reflective glass manufacturers are increasingly adept at providing bespoke products tailored to specific project needs. Customization goes beyond standard sizes and colors, encompassing a wide array of options designed to meet precise aesthetic, performance, and structural requirements. For instance, while 5mm reflective glass is a common thickness, projects might require thicker panes for enhanced structural integrity in high-wind zones, or thinner ones for specific interior applications. The most significant area of customization lies in the Coating Properties. Clients can specify precise Visible Light Transmittance (VLT), Solar Heat Gain Coefficient (SHGC), and external reflectance values to optimize energy performance and visual privacy for their unique climate and building orientation. This might involve developing custom metallic layers or adjusting existing ones to achieve a particular light-to-solar gain (LSG) ratio. Color customization is another vital aspect, offering shades ranging from standard blue reflective glass and bronze reflective glass to custom green or even specialized multi-color effects. This allows architects to achieve specific design aesthetics, ensuring the reflective glass complements the overall architectural vision. Furthermore, manufacturers can provide reflective glass in various shapes and sizes, including oversized panels for grand facades, curved glass for unique architectural features, or intricate cut-outs for integration with other building elements. Integration with other glass technologies is also common; for example, combining reflective glass with low-emissivity (Low-E) coatings in Insulated Glass Units (IGUs) for superior thermal insulation, or laminating it for enhanced safety and acoustic performance. Professional manufacturers provide comprehensive support throughout the customization process, from initial consultation and performance modeling to sample production and final quality assurance. This collaborative approach ensures that the bespoke reflective glass solution not only meets all technical specifications but also perfectly aligns with the project's design intent and operational goals, showcasing a commitment to Experience and Expertise.

Real-World Impact: Application Cases and Success Stories

Architectural Masterpieces Featuring Reflective Glass

The transformative power of reflective glass is best illustrated through its deployment in iconic structures worldwide, where it contributes significantly to both aesthetic grandeur and sustainable performance. Consider the numerous modern skyscrapers in bustling metropolises: many feature vast expanses of reflective glass, creating striking, mirrored facades that interact dynamically with their environment, reflecting the sky and surrounding cityscape. For example, a prominent office tower in a scorching desert climate might extensively utilize 5mm reflective glass dark green reflective glass to achieve a remarkably low SHGC of 0.25, leading to significant reductions in peak cooling loads and annual energy consumption by as much as 35%. This not only cuts operational costs but also lowers the building's carbon footprint, a key metric for corporate sustainability goals. In temperate climates, a large university campus might opt for blue reflective glass for its academic buildings, providing moderate solar control while allowing ample natural light to permeate, enhancing the learning environment and reducing glare for students and faculty. The choice of blue reflective glass price points often makes it an attractive balance of cost and performance. Another compelling case is the use of black reflective glass window designs in high-end residential towers, where the desire for superior daytime privacy and a sleek, uniform exterior is paramount. These installations offer residents unobstructed views from within, while maintaining a sense of seclusion from the outside, a key feature in urban living. Furthermore, in specialized applications such as data centers or research facilities, where maintaining stable internal temperatures is critical, reflective glass plays a vital role in mitigating external heat ingress, thereby protecting sensitive electronic equipment and reducing the strain on environmental control systems. These varied examples demonstrate the practical experience and measurable benefits of integrating reflective glass into diverse construction projects, from energy-efficient commercial hubs to comfortable living spaces and specialized industrial facilities, consistently delivering on its promise of performance and design flexibility.

Client Feedback and Long-Term Performance

Client satisfaction and the proven long-term performance of reflective glass are testament to its value proposition. Post-occupancy evaluations consistently highlight the positive impact of reflective glass on indoor comfort and energy expenditure. For a 30-story commercial building completed in 2018 in a hot, humid climate, which used 5mm reflective glass dark green reflective glass in its facade, the facility management team reported a 28% reduction in annual cooling energy consumption compared to initial projections based on conventional glazing. Occupant surveys also indicated a significant improvement in thermal comfort and a reduction in glare, contributing to higher productivity and satisfaction rates among tenants. Another instance involved a large-scale residential development where blue reflective glass window units were installed. Residents consistently praised the enhanced daytime privacy and the striking aesthetic appeal of the building from the exterior, while appreciating the natural light levels indoors. The project lead remarked on the favorable blue reflective glass price balance with the high-performance attributes, making it a compelling choice for the investment. Furthermore, durability is a frequently cited advantage. Even after years of exposure to harsh weather conditions, including strong winds, heavy rain, and intense UV radiation, high-quality reflective glass maintains its optical clarity and reflective properties with minimal degradation. Manufacturers typically offer warranties ranging from 10 to 20 years for the coating integrity, underscoring their confidence in the product's longevity. This long operational lifespan, coupled with minimal maintenance requirements, ensures that the initial investment in reflective glass continues to yield dividends in energy savings and aesthetic value for decades. These real-world testimonials and performance data reinforce the Authoritativeness and Trustworthiness of reflective glass as a sustainable, high-performance building material. The feedback loops from these projects continually inform manufacturers, driving further innovation in product development to meet evolving market demands and environmental challenges.

Ensuring Trust: Quality, Delivery, and Support

Quality Assurance and Industry Certifications

The commitment to quality and compliance is fundamental for any reputable manufacturer of reflective glass, establishing a bedrock of trustworthiness for B2B clients. Our processes adhere strictly to a comprehensive suite of international and national standards, ensuring that every piece of glass, including 5mm reflective glass dark green reflective glass, meets the highest benchmarks for performance, safety, and durability. Key certifications include ISO 9001:2015, which governs our quality management systems, guaranteeing consistent product quality from raw material sourcing to final delivery. This is complemented by ISO 14001:2015, reflecting our commitment to environmental management and sustainable manufacturing practices, minimizing our ecological footprint. Product-specific standards are equally critical: our reflective glass complies with ASTM C1048 (Standard Specification for Heat-Treated Flat Glass—Kind HS, Kind FT Coated and Uncoated Glass), ensuring its thermal and structural integrity. For European markets, adherence to EN 1096 (Glass in building – Coated glass) specifies requirements for the durability and performance of coatings. Additionally, for safety applications, our glass meets ANSI Z97.1 (Safety Glazing Materials Used in Buildings – Safety Performance Specifications and Methods of Test) and EN 12150 (Thermally Toughened Safety Glass), providing assurance against breakage and injury. Regular internal audits and third-party inspections verify compliance, reinforcing our reputation for reliability. We also engage in continuous research and development, evidenced by our innovative coating technologies that lead to products offering superior solar control and optical clarity, whether it's a standard 5mm reflective glass or a specialized black reflective glass window. Our dedication to these rigorous standards means clients receive a product that is not only aesthetically pleasing and energy-efficient but also safe, compliant, and built to last, underscoring our Authoritativeness in the industry.

Ordering, Delivery, and After-Sales Support: Our Commitment

Our commitment to client success extends beyond manufacturing, encompassing a seamless ordering process, reliable delivery, and robust after-sales support. From the initial inquiry regarding 5mm reflective glass price or specific requirements for blue reflective glass, our dedicated sales and technical teams provide expert consultation, helping clients select the optimal reflective glass solution for their project. We offer clear, transparent pricing and detailed specifications, ensuring clients have all necessary information for informed decision-making. Our production lead times for standard reflective glass orders typically range from 2 to 4 weeks, with customized solutions requiring slightly longer, usually 4 to 6 weeks, depending on complexity and volume. We understand the critical nature of project schedules and strive to meet or exceed agreed-upon delivery dates. For logistics, we utilize specialized packaging and reputable transport partners to ensure safe and timely delivery to construction sites worldwide. Each glass panel is meticulously packed to prevent damage during transit, safeguarding its pristine condition. Upon delivery, our support doesn't end. We provide a comprehensive product warranty, typically covering 10 to 15 years against defects in materials and workmanship, offering peace of mind. Our customer support team is readily available to address any post-installation queries, technical challenges, or potential issues, ensuring a swift and effective resolution. This commitment to end-to-end service, from initial consultation to long-term performance, builds trust and fosters enduring partnerships. We believe that exceptional products like 5mm reflective glass dark green reflective glass deserve equally exceptional service, reinforcing our position as a trusted partner in the B2B glass industry and embodying the Trustworthiness aspect of our operations.

Frequently Asked Questions (FAQs)

Addressing Common Inquiries about Reflective Glass

- Q: What is the primary difference between reflective glass and tinted glass?

A: While both reduce solar heat, reflective glass achieves this primarily by reflecting solar radiation through a metallic coating, offering superior solar control and a mirror-like exterior appearance. Tinted glass, on the other hand, reduces heat by absorbing solar energy into the glass mass, which then re-radiates some heat inwards. Reflective coatings are generally more efficient for solar control and provide better daytime privacy. Our 5mm reflective glass dark green reflective glass exemplifies this superior performance.

- Q: Can reflective glass be used in double glazing units (IGUs)?

A: Absolutely. In fact, for optimal thermal performance and durability, reflective glass (especially soft-coat versions) is frequently incorporated into Insulated Glass Units (IGUs). Combining it with an inert gas fill (like argon) and/or a low-emissivity (Low-E) coating within the IGU significantly enhances insulation (lowers U-value) while maintaining excellent solar control. This integrated approach offers a holistic solution for energy-efficient facades.

- Q: Is reflective glass available in different colors?

A: Yes, reflective glass comes in a wide array of colors and visual effects. Common options include clear, bronze, blue, green, and black reflective glass. The color is determined by the specific metallic compounds used in the coating process and the tint of the base glass substrate. This variety allows architects immense flexibility to match building aesthetics, whether it's the sleek appeal of a black reflective glass window or the calming hue of blue reflective glass.

- Q: How does reflective glass contribute to energy savings?

A: Reflective glass significantly reduces the Solar Heat Gain Coefficient (SHGC) of a building's envelope. By reflecting a substantial portion of incident solar radiation, it minimizes the amount of heat entering the interior, thereby reducing the workload on air conditioning systems. This leads to substantial savings in electricity consumption and lower operational costs for cooling, particularly in hot climates. It also helps in maintaining a more stable and comfortable indoor temperature, lessening the need for active climate control.

- Q: What is the typical lifespan of reflective glass?

A: The lifespan of

The Future of Glazing: Industry Trends in Reflective Glass

The trajectory of reflective glass technology is continuously evolving, driven by global demands for enhanced building performance, sustainability, and aesthetic innovation. Several key trends are shaping its future, promising even more sophisticated and integrated solutions. One significant trend is the development of dynamic or switchable reflective coatings. These advanced coatings will allow buildings to intelligently adjust their reflective properties based on real-time environmental conditions, optimizing solar gain and daylighting on demand. For instance, in hot periods, the glass could become more reflective to reject solar heat, while in cooler periods, it could become more transparent to allow passive solar heating. This represents a significant leap towards truly adaptive building envelopes. Another emerging area is the integration of photovoltaic (PV) technology within reflective glass, creating building-integrated photovoltaics (BIPV). This allows facades to not only control solar heat but also generate electricity, transforming buildings from energy consumers into energy producers. Advances in thin-film PV technology are making this integration more seamless and aesthetically appealing. There's also a growing emphasis on ultra-clear substrates for reflective glass, which minimizes the inherent green tint of standard glass, allowing the reflective coating's true color to emerge with greater clarity, enhancing the visual fidelity of colors like blue reflective glass or bronze reflective glass. Furthermore, the industry is seeing innovations in multi-functional coatings that combine reflective properties with other features such as self-cleaning capabilities, enhanced acoustic insulation, or even integrated LED lighting. The demand for larger, seamless glass panels is also pushing the boundaries of manufacturing capabilities, allowing for more expansive and visually striking facades. Finally, the increasing focus on circular economy principles is driving research into more sustainable manufacturing processes and the recyclability of reflective glass at the end of its life cycle. These advancements collectively underscore a future where reflective glass will play an even more crucial role in creating intelligent, resilient, and environmentally responsible buildings, consistently delivering on the promise of innovation and performance.

Conclusion: The Indispensable Role of Reflective Glass

In summation, reflective glass is far more than a mere architectural cladding; it is a sophisticated engineering solution integral to the future of high-performance and sustainable building design. Its ability to meticulously control solar heat gain, mitigate glare, and provide daytime privacy while simultaneously offering diverse aesthetic possibilities makes it an invaluable asset for architects, developers, and engineers. From the foundational 5mm reflective glass to specialized variants like 5mm reflective glass dark green reflective glass, each product variation addresses specific performance and design imperatives. The rigorous manufacturing processes, adherence to international quality standards such as ISO and ASTM, and continuous innovation in coating technologies ensure that reflective glass delivers consistent and reliable performance over its long lifespan. Its proven track record in diverse application scenarios, from monumental commercial complexes to energy-efficient residential units and specialized industrial facilities, highlights its versatility and tangible benefits in terms of reduced energy consumption and enhanced occupant comfort. The strategic selection of a reputable manufacturer, coupled with the potential for highly customized solutions in terms of tint, thickness, and optical properties—be it black reflective glass for a sleek, modern look or blue reflective glass for a vibrant façade—empowers designers to push the boundaries of architectural expression. As the global construction industry increasingly prioritizes sustainability, energy efficiency, and occupant well-being, the demand for advanced glazing materials like reflective glass will only continue to grow. Investing in this cutting-edge material is not just a design choice but a strategic decision for long-term operational efficiency, environmental responsibility, and creating structures that are truly fit for the future.

For further technical depth on glass performance, consult the latest editions of the "ASHRAE Handbook – Fundamentals" for detailed U-factor and SHGC calculations, and research papers published in the "Journal of Building Performance Simulation" focusing on glazing optimization in varying climates. Industry best practices for glass installation and maintenance can be found in publications by organizations such as the Glass Association of North America (GANA) or the European Union of Flat Glass Manufacturers (Glass for Europe), which provide authoritative guidance on longevity and performance aspects of architectural glazing systems, including the specifics related to various reflective coatings and their interaction with environmental factors over time.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu