The Process of Tempered Glass An Overview

Tempered glass, also known as toughened glass, is a type of safety glass that has been heat-treated to enhance its strength and resistance to thermal stress. This process is vital for ensuring that the glass can withstand various environmental conditions, making it an essential component in construction, automotive, and appliance industries. Understanding the process of tempered glass production helps in appreciating its properties and applications.

The manufacturing of tempered glass begins with selecting the right type of glass. Typically, soda-lime glass is used due to its affordability and availability. The first step in the tempered glass process is heating the glass to a temperature between 600°C to 700°C (about 1112°F to 1292°F). This heat treatment alters the internal structure of the glass, allowing it to be stronger than standard glass.

Once the glass reaches the required temperature, it is quickly cooled using a process known as quenching. This rapid cooling is fundamental to the tempering process. It is achieved by blowing cool air onto the glass surface, creating a temperature gradient. The outer layer cools faster than the inner part, causing the exterior to shrink and compress while the interior remains expanded. This compression in the outer layers increases the overall strength of the glass, enabling it to resist impact and thermal stresses effectively.

The two main types of tempering processes are the vertical and horizontal methods, which differ mainly in how the glass is heated and cooled. In vertical tempering, glass sheets are heated in a vertical position, while in horizontal tempering, the sheets are laid flat. The choice of process depends on the specific requirements of the glass product, such as its dimensions, intended use, and the desired properties.

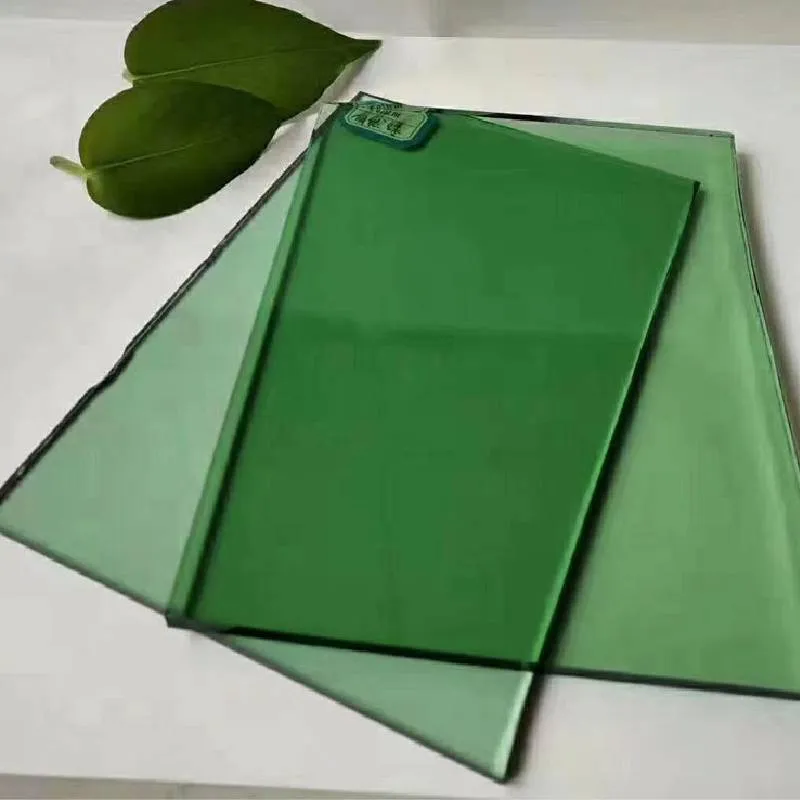

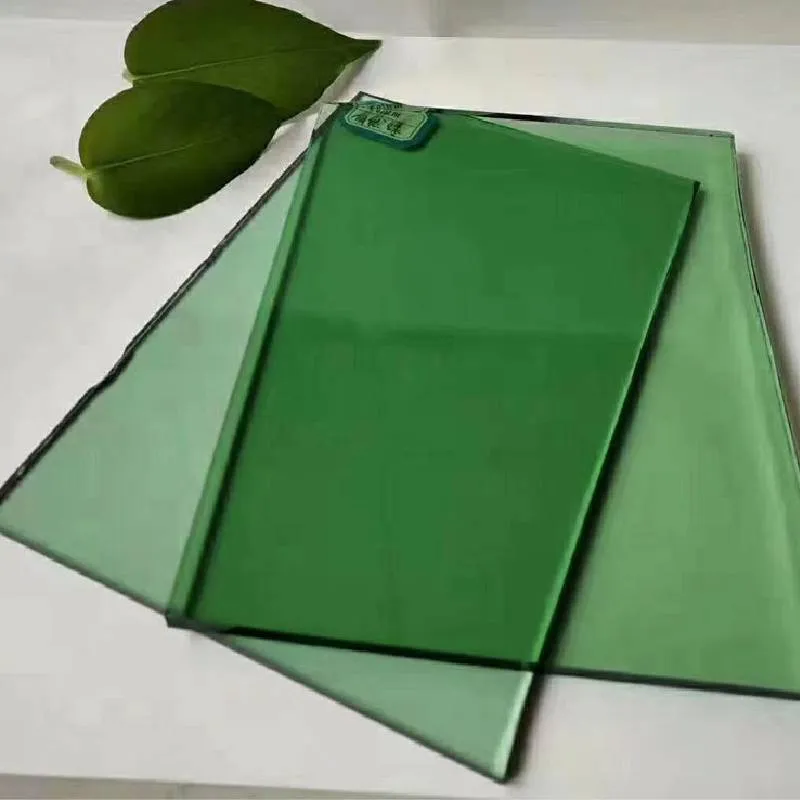

process of tempered glass

After the quenching process, tempered glass undergoes rigorous quality control inspections. These inspections ensure that the glass meets all safety standards and specifications. Quality assurance tests include checking for any surface defects, measuring the glass thickness, and assessing the overall clarity. Any flaws detected are rectified, as even minor imperfections can compromise the integrity of the tempered glass.

One of the most significant advantages of tempered glass is its safety feature. When broken, tempered glass shatters into small, blunt pieces that are less likely to cause injury, unlike traditional glass, which breaks into sharp shards. This safety aspect makes it an ideal choice for various applications, including shower doors, glass doors, facades, and even vehicle windows.

Moreover, tempered glass is resistant to thermal stress. It can withstand temperature changes of up to 200°C (approximately 392°F) without breaking. This property makes it especially suitable for use in areas where thermal fluctuations are common, such as in buildings with large windows or glass facades.

In conclusion, the process of tempered glass production involves careful heating and rapid cooling techniques that enhance its strength and thermal resistance. With its numerous advantages, tempered glass has become a preferred choice in many industries. From safety to durability, its unique properties cater to various applications, ensuring that users benefit from high-performance glass solutions. As technology advances, the process and applications of tempered glass are likely to evolve further, reinforcing its significance in modern architecture and design.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu