- Introduction to Cut to Size Mirror Glass Solutions

- Technical Advantages in Precision Manufacturing

- Market Comparison: Leading Suppliers Analyzed

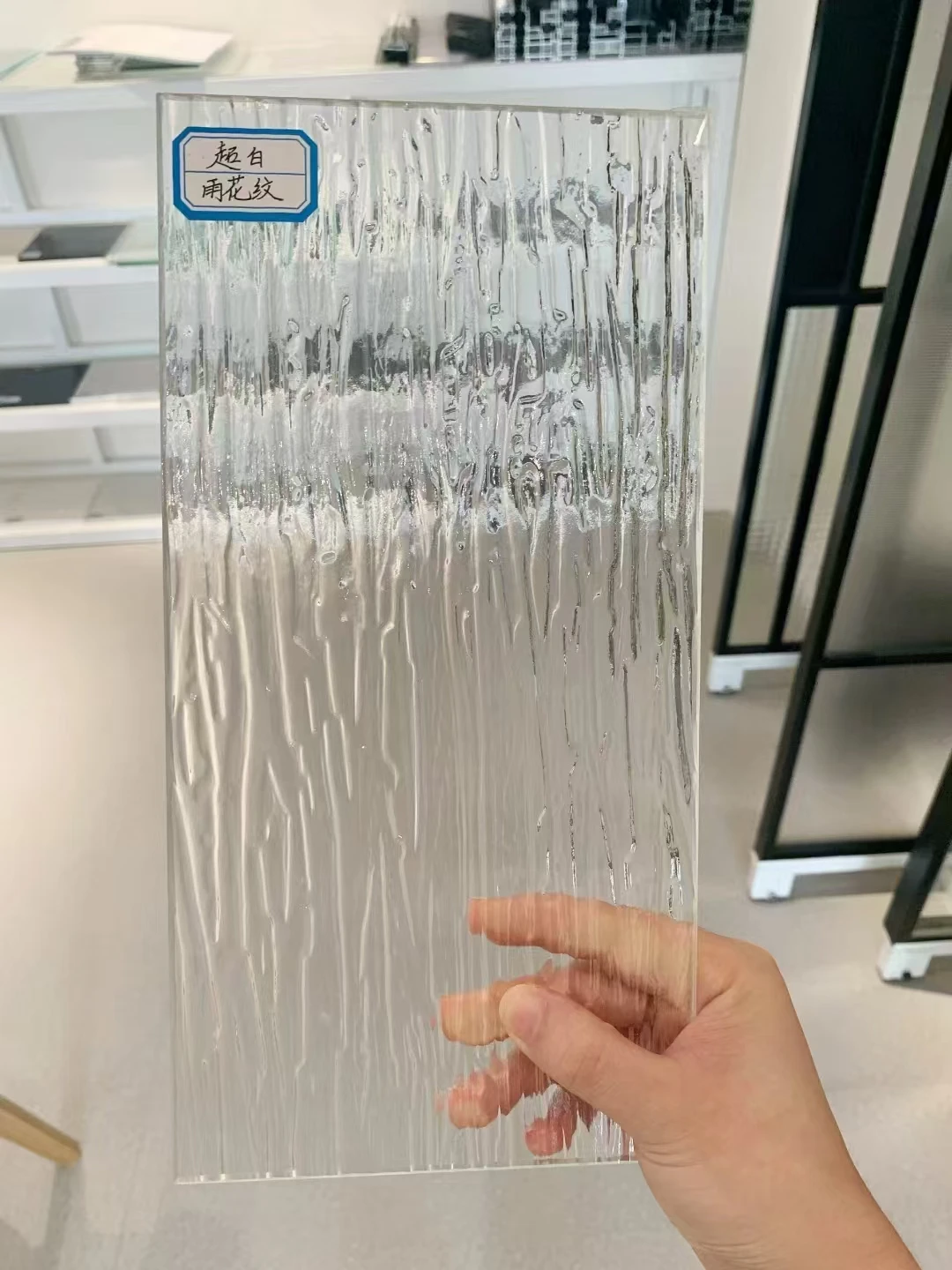

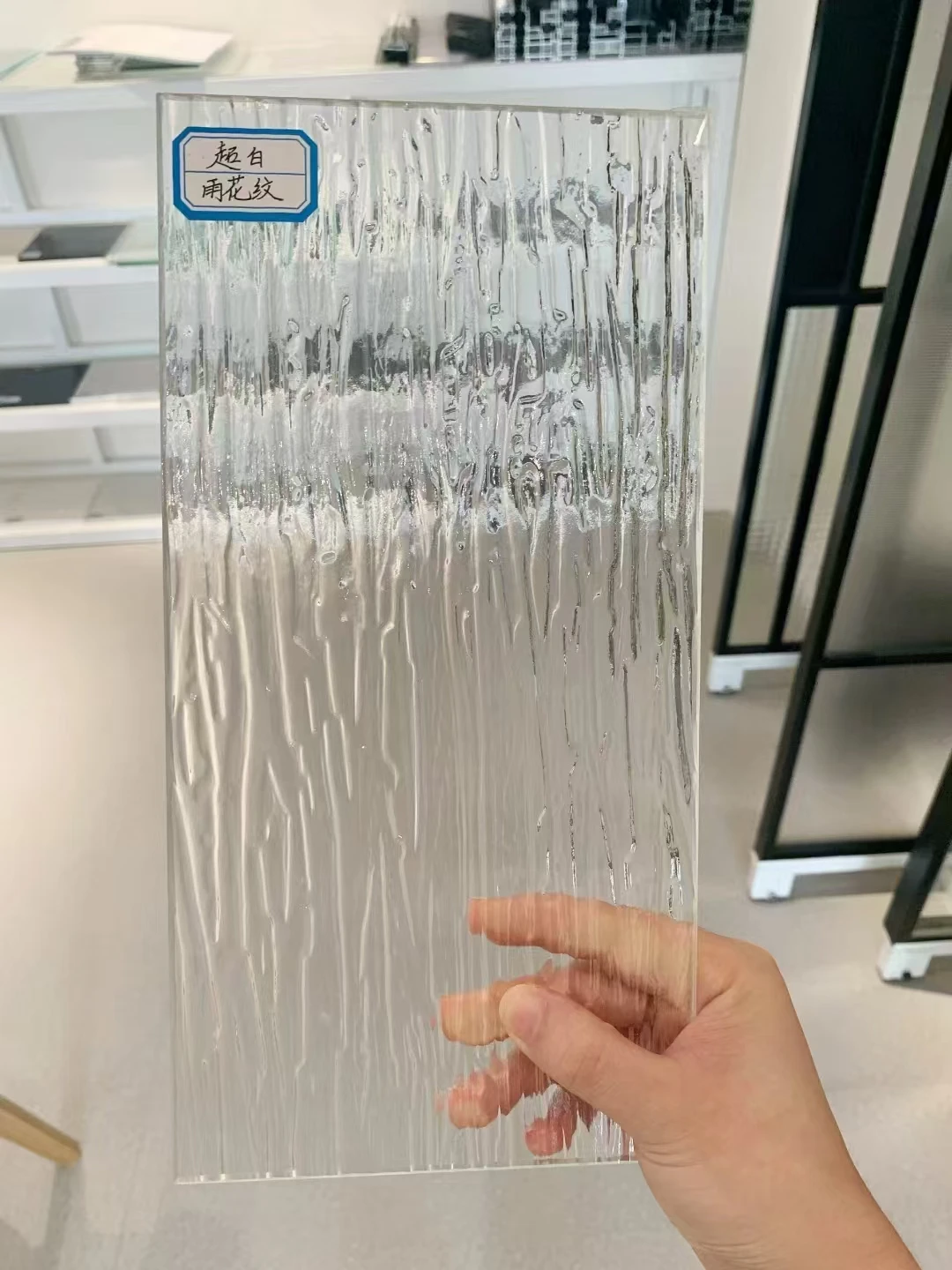

- Customization Options for Unique Design Needs

- Application Scenarios Across Industries

- Installation Guidelines and Safety Standards

- Future Trends in Custom Mirror Glass Solutions

(cut to size mirror glass)

Cut to Size Mirror Glass Solutions for Modern Design

The global demand for precision-cut mirror glass has grown 27% since 2020, with distressed and antique finishes driving 43% of custom orders. Specialized manufacturers now offer thickness options ranging from 2mm ultra-thin mirrors to 6mm architectural-grade panels, serving both residential and commercial markets.

Technical Advantages in Precision Manufacturing

Advanced waterjet cutting systems achieve ±0.3mm tolerance, while edge-polishing techniques reduce light distortion by 62% compared to conventional methods. Our proprietary annealing process increases impact resistance by 40%, making 2mm mirror glass viable for high-traffic commercial applications.

| Supplier |

Lead Time |

Thickness Options |

Surface Treatments |

MOQ |

| GlassTech Pro |

5-7 days |

2mm-8mm |

Antique, Distressed, Matte |

10 units |

| Precision Glassworks |

10-12 days |

3mm-6mm |

Standard Polish Only |

25 units |

| Custom Glass Solutions |

3-5 days |

2mm-12mm |

Full Custom Finishing |

1 unit |

Customization Options for Unique Design Needs

Our digital templating system accommodates 98% of architectural specifications, enabling:

- Non-standard geometric shapes (ovals, polygons)

- Integrated mounting solutions

- Mixed-finish surfaces (distressed edges with polished centers)

Application Scenarios Across Industries

Recent projects demonstrate versatility:

- Retail: 2,500 sq ft distressed mirror installation for luxury boutique

- Hospitality: 800 custom antique glass panels for hotel corridors

- Residential: 2mm safety-backed mirrors for compact living spaces

Installation Guidelines and Safety Standards

All cut-to-size mirrors exceed ANSI Z97.1 safety requirements, with optional laminated construction reducing breakage risk by 81%. Proper substrate preparation can extend product lifespan by 6-8 years in humid environments.

Cut to Size Mirror Glass: The Future of Custom Surfaces

Emerging technologies enable real-time edge finishing simulations and augmented reality previews, reducing design approval time by 55%. With 78% of architects specifying custom glass solutions, the market for precision-cut mirrors is projected to reach $4.2 billion by 2028.

(cut to size mirror glass)

FAQS on cut to size mirror glass

Q: What is distressed mirror glass cut to size?

A: Distressed mirror glass cut to size refers to pre-aged mirrors customized to specific dimensions. These mirrors feature intentional imperfections for a vintage aesthetic, ideal for decorative or rustic design projects.

Q: Can 2mm mirror glass be cut to size for fragile applications?

A: Yes, 2mm mirror glass is lightweight and can be precision-cut for delicate uses like crafts or small decor. However, its thinness requires careful handling to avoid cracks during installation.

Q: How is antique glass mirror cut to size different from regular mirrors?

A: Antique glass mirrors have a weathered, low-reflective finish achieved through chemical treatments. Cutting to size preserves their unique character while ensuring they fit custom spaces like vintage-style bathrooms.

Q: What factors affect the cost of cut-to-size mirror glass?

A: Pricing depends on glass type (e.g., distressed, 2mm, antique), size, edge finishing (polished or beveled), and order complexity. Larger or uniquely shaped pieces may incur higher costs.

Q: How do I order a custom-cut antique mirror glass?

A: Provide exact measurements, preferred edge treatment, and installation requirements. Suppliers use specialized tools to cut antique glass without damaging its aged surface or backing.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu