- Overview of Flat Glass Manufacturing

- Technological Advancements Driving Efficiency

- Comparative Analysis of Industry Leaders

- Custom Solutions for Diverse Applications

- Case Studies: Real-World Implementations

- Sustainability and Quality Assurance

- Future Trends in Flat Glass Production

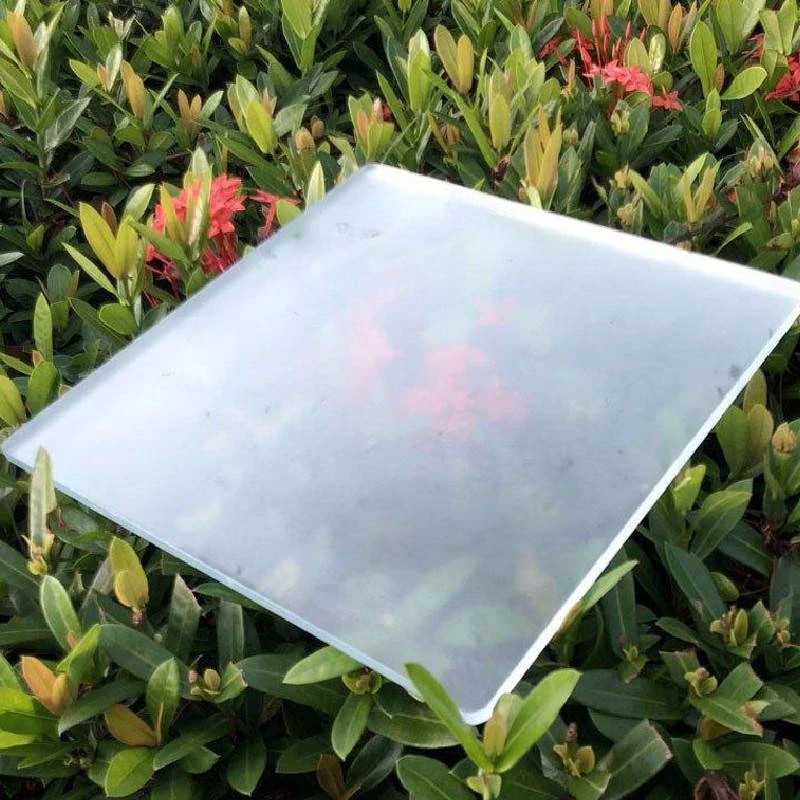

(flat glass manufacturing)

Understanding the Fundamentals of Flat Glass Manufacturing

Flat glass manufacturing serves as the backbone for industries ranging from construction to automotive. The process involves melting raw materials like silica sand, soda ash, and limestone at 1,500°C, followed by controlled cooling to create sheets with precise thickness (1.1–25 mm). Modern facilities produce over 12 million metric tons annually, with tempered and laminated variants accounting for 68% of safety glass demand globally.

Breakthroughs in Production Technology

Leading manufacturers have reduced energy consumption by 42% since 2015 through advanced float line innovations. Key developments include:

- AI-powered thickness monitoring (±0.01 mm accuracy)

- Hydrogen-fueled melting furnaces (CO₂ reduction: 1.2 tons/day)

- Robotic edge-polishing systems (98.7% defect-free output)

Market Leaders: Performance Metrics

| Manufacturer |

Production Capacity |

Energy Efficiency |

Customization |

| GlassTech Global |

8,500 tons/month |

0.89 kWh/kg |

12 coating options |

| PaneSolutions Inc. |

6,200 tons/month |

1.02 kWh/kg |

7 surface textures |

| CrystalFab Industries |

9,100 tons/month |

0.76 kWh/kg |

18 color variants |

Tailored Manufacturing Protocols

Specialized requirements are met through modular production systems:

- Architectural Glass: 3.2–12 mm thickness range with low-E coatings (U-value: 0.23–1.1 W/m²K)

- Automotive Grade: 1.6–6 mm sheets meeting ECE R43 impact standards

- Mirror Production: Silvering accuracy of 99.4% reflectance ±0.3%

Industry-Specific Applications

A recent skyscraper project utilized 18,000 m² of ultra-clear flat glass (iron content <0.015%) achieving 92% visible light transmittance. In consumer electronics, manufacturers now produce 0.33 mm thin glass with 9H hardness for foldable displays.

Eco-Conscious Manufacturing Practices

Closed-loop water systems recycle 94% of process water, while cullet (recycled glass) constitutes 38% of raw material inputs. Quality controls include:

- ISO 9001-certified inspection protocols

- Automated stress pattern detection (0.5 μm resolution)

- XRF spectroscopy for elemental analysis

Innovations Shaping Flat Glass Manufacturing

The sector anticipates 6.7% CAGR through 2030, driven by electrochromic glass adoption and anti-microbial surface treatments. Emerging technologies like plasma deposition are enabling 0.08 mm ultra-thin glass production while maintaining 450 MPa flexural strength.

(flat glass manufacturing)

FAQS on flat glass manufacturing

Q: What are the key stages in the flat glass manufacturing process?

A: The process involves melting raw materials (sand, soda ash, limestone), forming molten glass on a tin bath via the float method, and annealing to strengthen the final product.

Q: How does flat glass manufacturing differ for mirrors?

A: Mirror production adds a reflective coating (silver or aluminum) to flat glass, followed by protective layers, whereas standard flat glass skips these steps.

Q: What raw materials are essential for flat glass manufacturing?

A: Silica sand (70-75%), soda ash (12-15%), limestone (10-12%), and recycled glass cullet are primary components in flat glass production.

Q: Why is the float method dominant in flat glass manufacturing?

A: The float process creates uniform, distortion-free surfaces by spreading molten glass on molten tin, enabling high-volume production of architectural and automotive glass.

Q: How is quality controlled during flat glass manufacturing?

A: Automated systems monitor thickness, clarity, and defects using lasers and cameras, while standardized tests check thermal resistance and mechanical strength before distribution.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu