The Evolution of Plate Glass Manufacturing Trends and Innovations

Plate glass, known for its smooth surface and clarity, has become an indispensable material in various industries, including construction, automotive, and interior design. The manufacturing process of plate glass has seen significant evolution over the years, driven by technological advancements and changing market demands. This article explores the current landscape of plate glass manufacturers, highlighting trends, innovations, and the future of this vital industry.

Understanding Plate Glass

Plate glass refers to a type of flat glass that is generally manufactured in large sheets, showcasing excellent optical quality and smoothness. Traditionally, plate glass was produced through a manual process involving blowing and grinding techniques. However, the introduction of float glass technology in the mid-20th century revolutionized the industry. This innovative method involved floating molten glass on a bed of molten tin, resulting in a uniform thickness and exceptionally smooth surface. Today, float glass remains the standard for producing large, high-quality sheets.

Current Market Trends

The global plate glass market has been experiencing steady growth due to rising construction activities and increased demand for energy-efficient buildings. Manufacturers are increasingly focused on producing high-performance glass that meets energy efficiency standards while maintaining aesthetic appeal. The trend towards sustainability has propelled the development of low-emissivity (Low-E) glass, which helps to reduce energy consumption in buildings.

Another trend is the increasing use of smart glass technologies. Smart glass, which can change its properties in response to environmental stimuli, offers exciting possibilities for energy management and privacy in commercial spaces. Manufacturers are investing in research to enhance the functionality and affordability of smart glass, making it a more viable option for everyday applications.

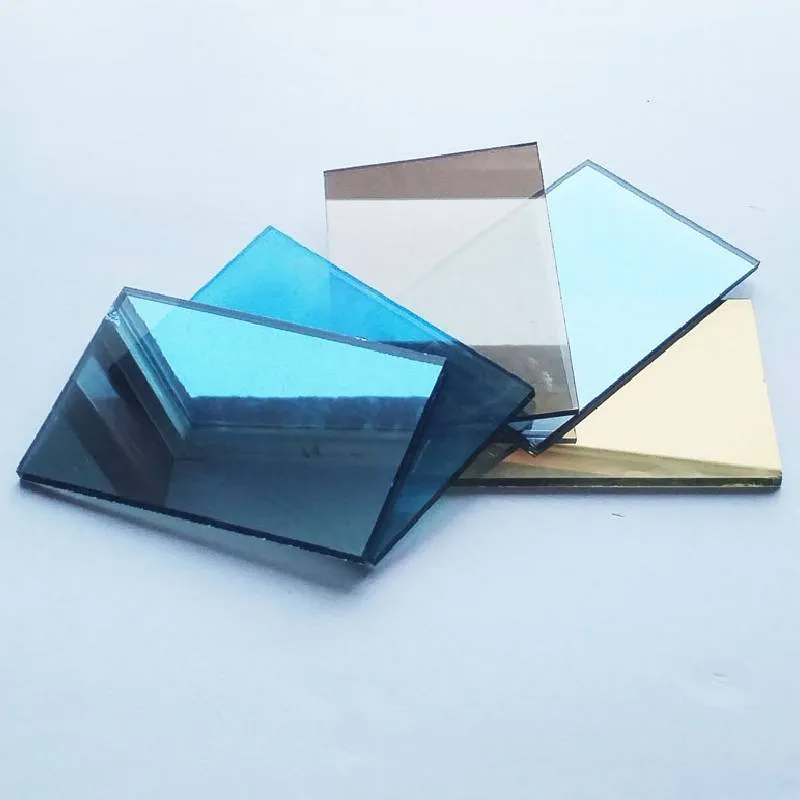

plate glass manufacturers

Innovations in Production Techniques

The quest for efficiency and quality has driven innovations in plate glass manufacturing processes. Automation and computer-aided design (CAD) have streamlined production lines, significantly reducing labor costs and increasing precision. Advanced machinery allows for the rapid cutting and processing of glass, ensuring that manufacturers can meet growing demands without compromising quality.

Moreover, advancements in coating technologies have allowed manufacturers to enhance the properties of plate glass. Coatings can improve scratch resistance, UV protection, and thermal insulation, making the glass more durable and versatile. These innovations not only meet consumer expectations but also comply with stringent building codes and regulations.

Challenges and Future Prospects

Despite the positive growth indicators, plate glass manufacturers face several challenges. Economic fluctuations and trade tensions can impact raw material costs, while competition from alternative materials, such as plastics and composites, poses a threat. Manufacturers must continuously innovate and offer value-added products to maintain their market position.

Looking ahead, the future of plate glass manufacturing appears promising. With the ongoing focus on sustainability, manufacturers are expected to invest in eco-friendly production practices, including recycling initiatives and reductions in carbon emissions. As global demand for energy-efficient solutions continues to rise, the role of plate glass in the building and automotive sectors will become increasingly significant.

In conclusion, plate glass manufacturers are navigating a dynamic landscape marked by technological advancements, evolving consumer preferences, and environmental considerations. The industry must adapt to these changes while maintaining a commitment to quality and innovation. As the demand for high-performance glass grows, manufacturers that embrace these trends will be well-positioned to thrive in the years to come.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu