Understanding Silver Mirror Materials A Reflection on Quality and Versatility

Silver mirrors, known for their exceptional clarity and brightness, have been a staple in decorative art and practical applications for centuries. The term silver mirror material generally refers to a reflective surface made primarily of silver, which is known for its impressive optical properties. This article explores the characteristics, production techniques, and diverse applications of silver mirror materials, highlighting their significance in both historical and contemporary contexts.

Characteristics of Silver Mirror Materials

Silver mirrors are renowned for their high reflectivity, often exceeding 95% in certain wavelengths of light. This remarkable property is due to silver's atomic structure, which allows it to reflect a broad spectrum of visible light with minimal distortion. As a result, silver mirrors can produce highly accurate and bright images, making them ideal for both decorative and practical uses.

In addition to their reflective qualities, silver mirrors are also valued for their durability. When appropriately coated, silver mirrors can withstand various environmental factors, including moisture and temperature changes. The traditional silver backing can be susceptible to tarnishing; however, modern techniques often involve additional protective layers that enhance longevity and maintain the mirror's pristine appearance.

Production Techniques

The production of silver mirror materials involves a meticulous process that balances artistry and technology. The most common method is the chemical deposition of silver onto a glass substrate. Initially, a thin layer of silver nitrate is applied to the glass surface. Upon exposure to a reducing agent, the silver ions are transformed into metallic silver, forming a reflective layer. This method has remained popular due to its efficiency and effectiveness.

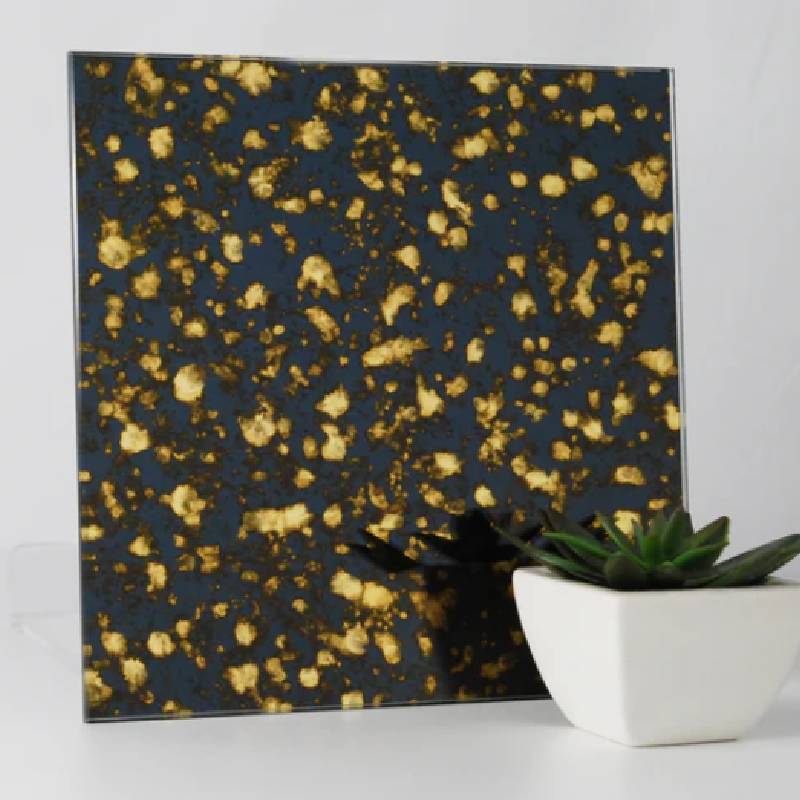

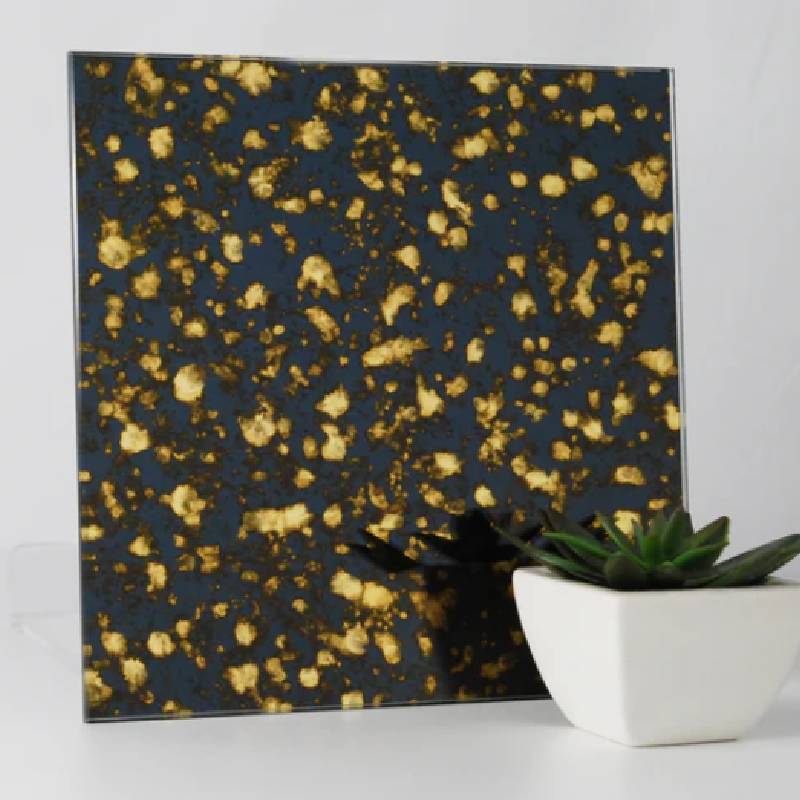

silver mirror material

Moreover, technological advancements have introduced alternatives like vacuum deposition, where silver is vaporized and then condensed onto the glass surface under vacuum conditions. This technique allows for improved control over thickness and uniformity, resulting in higher-quality mirrors. After the silver layer is deposited, mirrors are often coated with additional materials—such as paint or lacquers—to protect against tarnishing and enhance their durability.

Applications of Silver Mirrors

Silver mirror materials serve various functions across multiple industries, solidifying their status as a versatile choice. In the realm of interior design, silver mirrors are used extensively as decorative accents, enhancing the aesthetic appeal of spaces by creating an illusion of depth and openness. The reflective properties of silver mirrors also make them popular in the fashion industry, where they are utilized in fitting rooms and boutiques to provide customers with a clear view of garments.

In scientific and medical fields, silver mirrors play a critical role. For instance, they are employed in optical instruments such as telescopes and microscopes, where precise reflection is vital for accurate observations. Moreover, in the field of laser technology, silver mirrors are integral components in laser cavities due to their high reflectance and low absorption characteristics.

Additionally, silver mirrors have found a place in cultural contests and exhibitions, where they are often used as trophies or awards, symbolizing excellence and achievement. Their reflective nature not only serves a functional purpose but also embodies the values of clarity and brilliance appreciated in various cultures around the world.

Conclusion

Silver mirror materials exemplify a merging of utility and elegance, making them indispensable in many domains. Their high reflectivity, durability, and versatility ensure that they remain relevant in both everyday and specialized applications. As technology continues to evolve, the methods of production will likely advance, leading to even more innovative uses for silver mirrors. Whether in enhancing home decor or facilitating scientific discovery, silver mirrors will continue to reflect the brilliance of human ingenuity and creativity for years to come.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu