The Versatility of Float Flat Glass A Modern Marvel

Float flat glass is an incredible innovation that has found its way into numerous industries, revolutionizing the way we view transparency, safety, and aesthetics. To understand its significance, we must first delve into the processes that create this remarkable material and explore its myriad applications.

The production of float flat glass is a sophisticated and meticulous process. It starts with the melting of raw materials, typically silica sand, soda ash, and limestone, in a furnace at temperatures exceeding 1,700 degrees Celsius. This molten mixture is then floated on a bed of molten tin, which creates a perfectly smooth and flat surface as it cools. This method not only produces glass that is uniform in thickness but also free of distortions, making it ideal for a wide range of uses.

One of the foremost applications of float flat glass is in the construction industry. It is widely utilized in both residential and commercial buildings for windows and facades, allowing natural light to permeate while providing insulation and energy efficiency. With the increasing emphasis on sustainability, low-emissivity (Low-E) glass variants have emerged, which help reduce energy consumption by reflecting heat back indoors during winter and preventing heat from entering during summer. This adaptability leads to a reduction in heating and cooling costs, making buildings more eco-friendly.

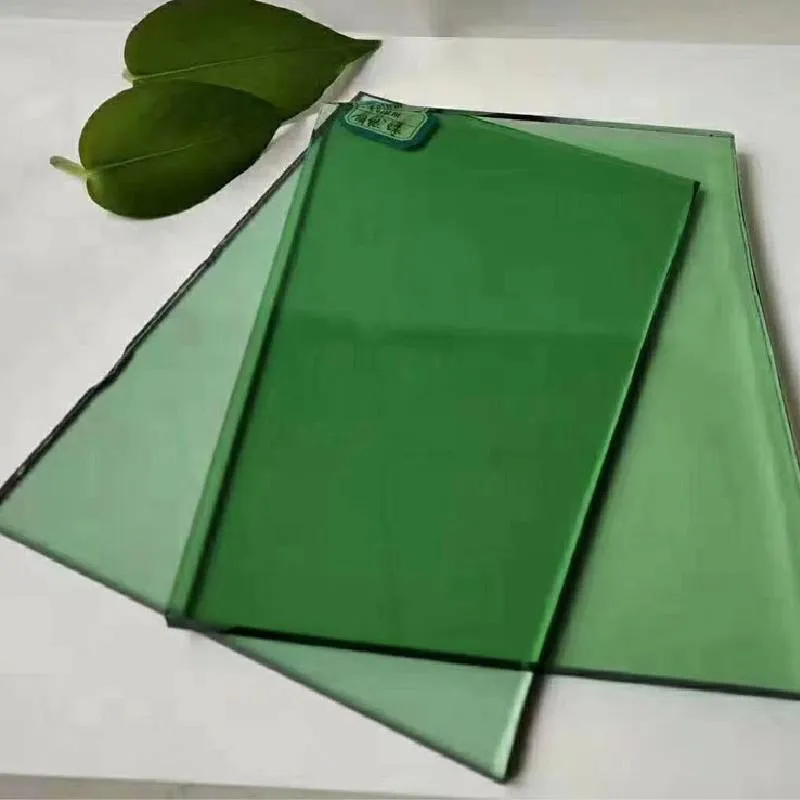

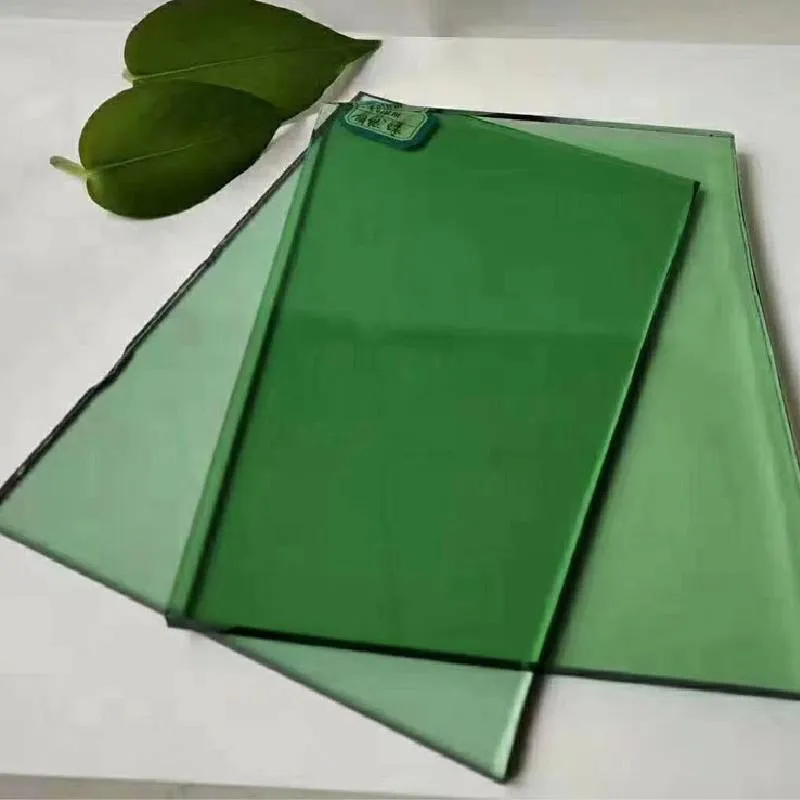

float flat glass

In addition to construction, float flat glass plays a crucial role in the automotive industry. Modern vehicles are designed with large glass panels for visibility and aesthetic appeal. Float glass is used in windshields, side windows, and sunroofs, offering safety and durability. Laminated and tempered variants enhance strength and shatter resistance, providing not only protection for passengers but also contributing to the vehicle’s overall design.

The use of float flat glass extends into the realm of interior design and furniture. From glass partitions and tables to decorative mirrors, its versatility allows for creative expression in any space. Designers appreciate its ability to create an illusion of spaciousness, reflecting light and making interiors appear larger and more open. Customization options, including tinted or frosted finishes, further expand its aesthetic appeal, catering to diverse consumer preferences.

Moreover, float flat glass is increasingly being utilized in technology, specifically in screens for smartphones, televisions, and other electronic devices. Its clarity and durability make it a preferred material for manufacturing screen protectors, ensuring that devices withstand the rigors of daily use without compromising functionality.

In conclusion, float flat glass is a testament to modern engineering and versatility. Its applications span numerous fields, from architecture and automobiles to design and technology. As we continue to innovate and prioritize sustainability, the role of float flat glass in enhancing our environments and lives will only grow, making it a cornerstone of contemporary manufacturing and design. This remarkable material not only meets our functional needs but also enriches our visual and aesthetic experiences in everyday life.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu