The float glass manufacturing process represents a revolutionary advancement in the production of flat glass, which dominates the industry due to its superior quality and cost-effectiveness. This article delves into this sophisticated method, examining it through the lens of expertise and real-world application, providing insights from seasoned professionals involved in the field.

At the heart of the float glass production process lies the concept of floating molten glass on a bed of molten tin. This method, first developed and commercialized by Sir Alastair Pilkington in the 1950s, ensures that the resulting glass sheets have a perfectly uniform thickness and remarkably smooth surfaces. The journey begins with the preparation of raw materials silica sand, soda ash, and limestone, combined with cullet to ease melting. These ingredients are melted in a furnace at temperatures exceeding 1700°C, creating a viscous molten glass.

Expertise is paramount during the refining stage, where impurities and air bubbles are meticulously removed to prevent defects. The molten glass is then carefully channeled onto the molten tin bath. Professionals in the industry emphasize the critical controlled environment of this stage—temperature precision and atmospheric conditions are maintained rigorously to prevent oxidation and ensure optimal glass quality.

As the glass floats across the tin, its temperature gradually decreases, allowing it to solidify into a continuous ribbon. This is where experience plays a pivotal role. Operators must adeptly manage the cooling process, known as annealing, in a controlled environment called the annealing lehr. This gradual cooling alleviates internal stresses, ensuring the glass doesn’t crack or warp over time. Seasoned technicians highlight the importance of precise temperature regulation through this stage, recognizing it as crucial for maintaining structural integrity and optical clarity.

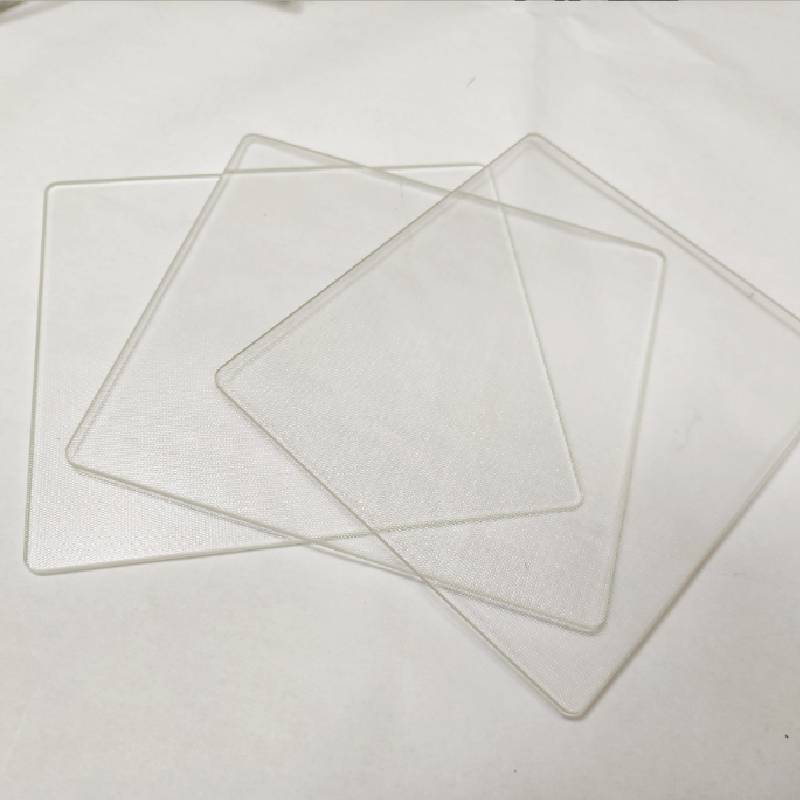

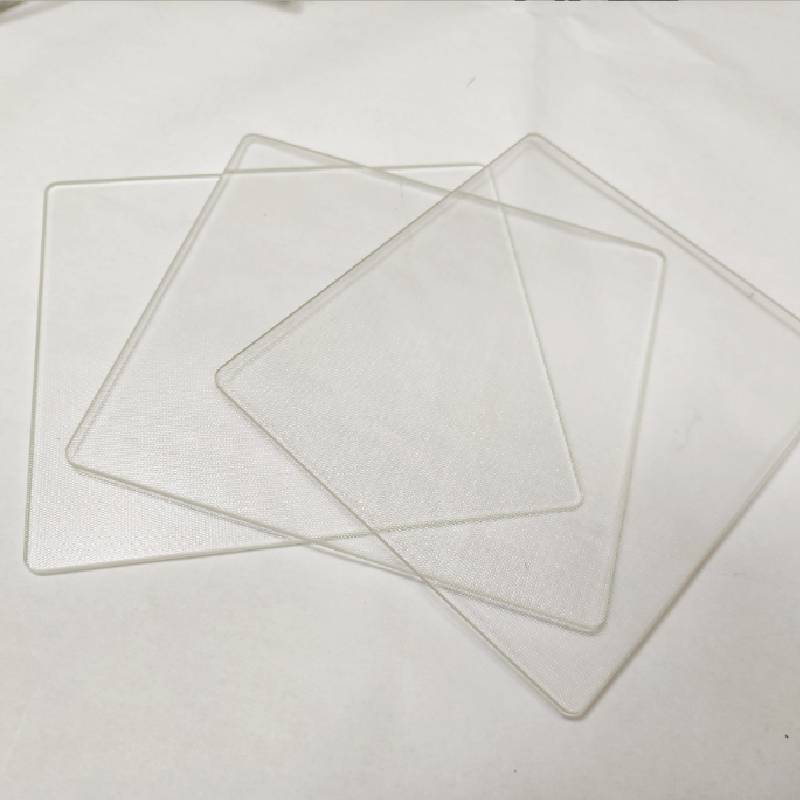

float glass manufacturing process

The subsequent cutting and inspection phases leverage both advanced technology and human expertise. Automated systems are employed to cut the glass into desired dimensions with pinpoint accuracy, while high-skilled inspectors conduct thorough quality checks. Their strategic and trained eye is essential in detecting imperfections that machines might miss, ensuring only the highest quality products reach the market.

The synthesis of technology and human acumen underscores the authoritative nature of successful float glass manufacturing operations.

The trustworthiness of float glass—often used in automotive, construction, and solar energy applications—stems from this meticulous production process. Manufacturers, guided by authoritative standards, proactively address sustainability concerns. Efforts include optimizing energy consumption and incorporating recycled glass, demonstrating a commitment to environmental responsibility.

In conclusion, the float glass manufacturing process epitomizes precision engineering and the harmonious blend of technology and human expertise. Its continued evolution reflects the industry's dedication to quality, efficiency, and sustainability, reinforcing its position as a trusted pillar of modern glass production. For businesses looking to invest in or utilize float glass, understanding this process is crucial, assuring stakeholders of both the expertise and reliability that underpin each pane of glass produced.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu