The Evolution and Significance of Toughened Glass Factories

Toughened glass, also known as tempered glass, has become a crucial material in modern architecture, automotive industries, and a variety of consumer products. The rise of toughened glass factories is a reflection of the growing demand for safety, durability, and aesthetic quality in glass products. This article explores the evolution, manufacturing processes, applications, and the significance of toughened glass factories in today's market.

The Evolution of Toughened Glass

The idea of enhancing glass's properties to withstand stress dates back to the late 19th century, but it gained significant traction in the late 20th century. With the increasing need for safer and more durable materials, the toughened glass industry began to thrive. Factories dedicated to the production of toughened glass emerged, utilizing advanced techniques to transform ordinary glass into a stronger, more reliable material.

The manufacturing process involves heating the glass to a high temperature, typically around 600 to 700 degrees Celsius, and then rapidly cooling it. This process induces compressive stresses on the surface, making toughened glass significantly stronger than untreated glass and able to resist thermal shocks. The emergence of specialized factories equipped with state-of-the-art technology has allowed for mass production and the ability to meet varying consumer demands.

Manufacturing Processes

The process of producing toughened glass involves several key steps

1. Cutting and Shaping Raw glass sheets are cut and shaped according to specifications. This initial stage is crucial, as any imperfections can lead to weaknesses in the final product.

2. Heating The shaped glass is then placed in a furnace where it is heated evenly to the required temperature. This stage is critical in developing the glass's strength.

3. Quenching After reaching the desired temperature, the glass is rapidly cooled by passing it through a system of high-velocity air jets. This cooling process is known as quenching and solidifies the glass structure.

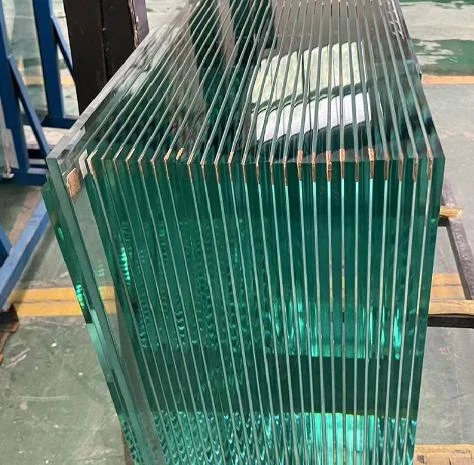

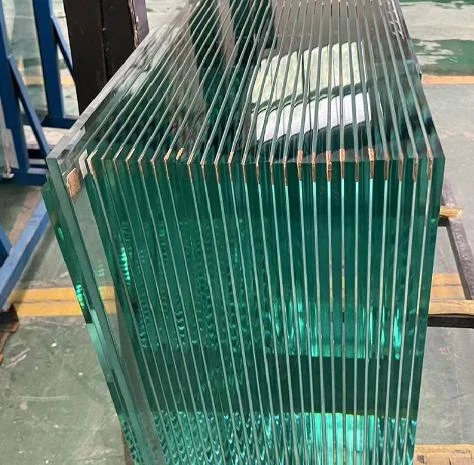

toughened glass factory

4. Testing and Quality Control Toughened glass undergoes rigorous testing to ensure it meets safety standards and specifications. Factories often implement strict quality control measures, checking for stress points, clarity, and overall structural integrity.

5. Finishing After passing quality checks, the glass may be polished or treated further to enhance aesthetic qualities, such as smoothness or tinting.

Applications of Toughened Glass

The range of applications for toughened glass is vast. In architecture, it is used for windows, facades, and balustrades, providing safety and thermal insulation without sacrificing aesthetic appeal. In the automotive industry, toughened glass is commonly found in windshields and side windows, offering protection and enhancing the design of vehicles.

Furthermore, toughened glass is utilized in commercial settings, such as storefronts and partitions, as its strength can bear significant impacts and stresses. In the home, toughened glass is a popular choice for shower doors, tabletops, and kitchen splashes, combining style with safety.

Significance of Toughened Glass Factories

Toughened glass factories play a pivotal role in the glass manufacturing industry. They not only contribute to the economy by providing jobs and sustaining local businesses, but they also help in advancing technology and innovation in glass production. As consumer awareness of safety and design continues to grow, these factories are becoming increasingly significant.

In addition, the environmental impact of toughened glass production is becoming a focus. Many factories are adopting more sustainable practices, such as recycling scrap glass and utilizing energy-efficient technologies, to minimize their carbon footprint. The industry's shift towards sustainability reflects a broader trend in manufacturing, where eco-friendly practices are not just encouraged but expected.

Conclusion

The emergence and proliferation of toughened glass factories underscore a significant development in material science and manufacturing. These facilities not only meet the growing demand for safer and more durable glass products but also drive innovation and sustainability in the industry. As urban environments continue to evolve and consumers seek reliable materials, toughened glass will undoubtedly remain at the forefront, shaping the architecture of our future and enhancing the quality of our daily lives.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu