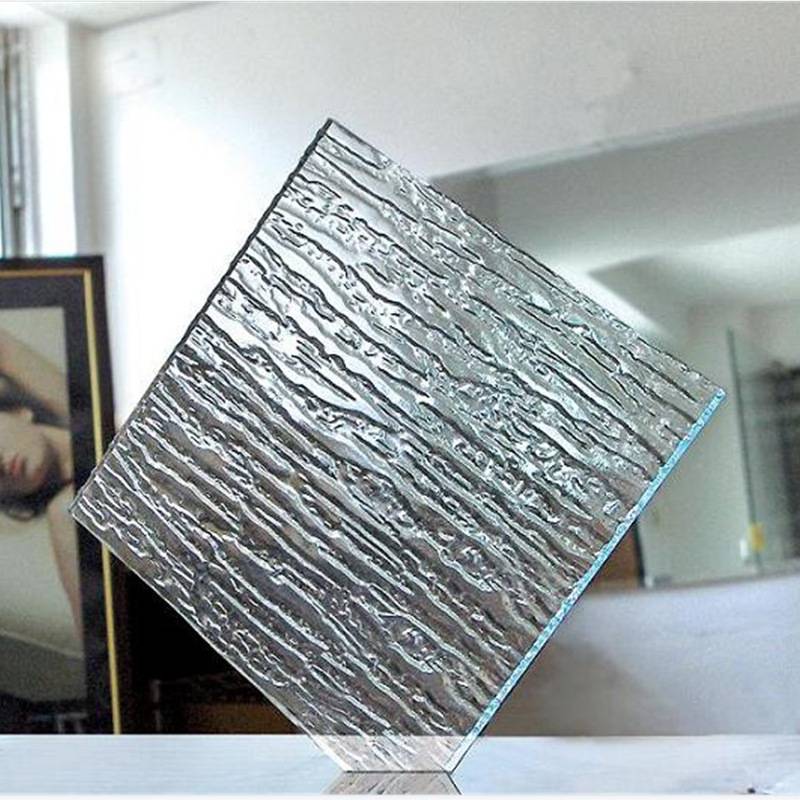

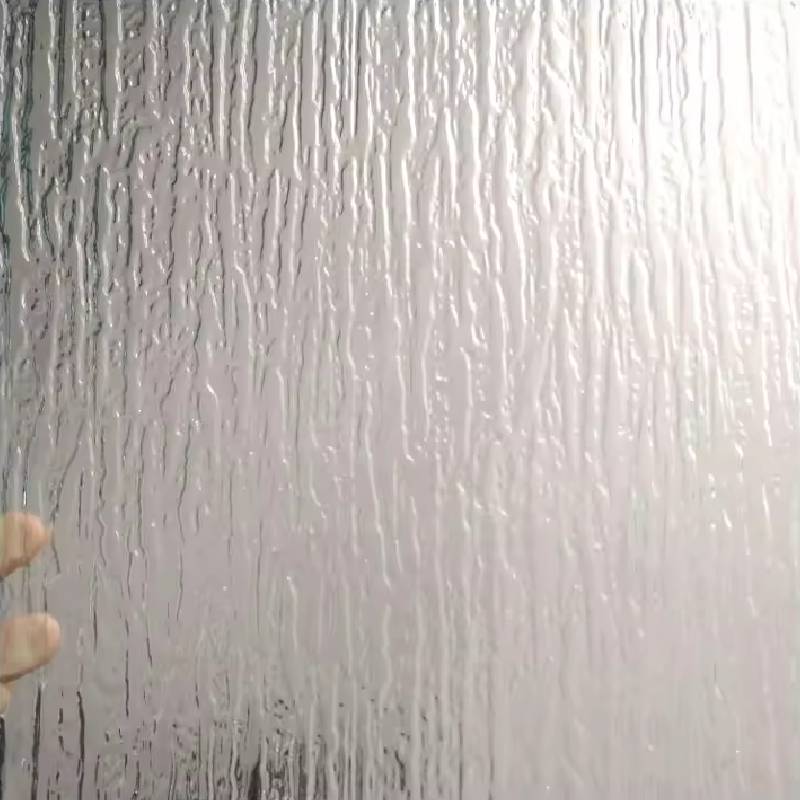

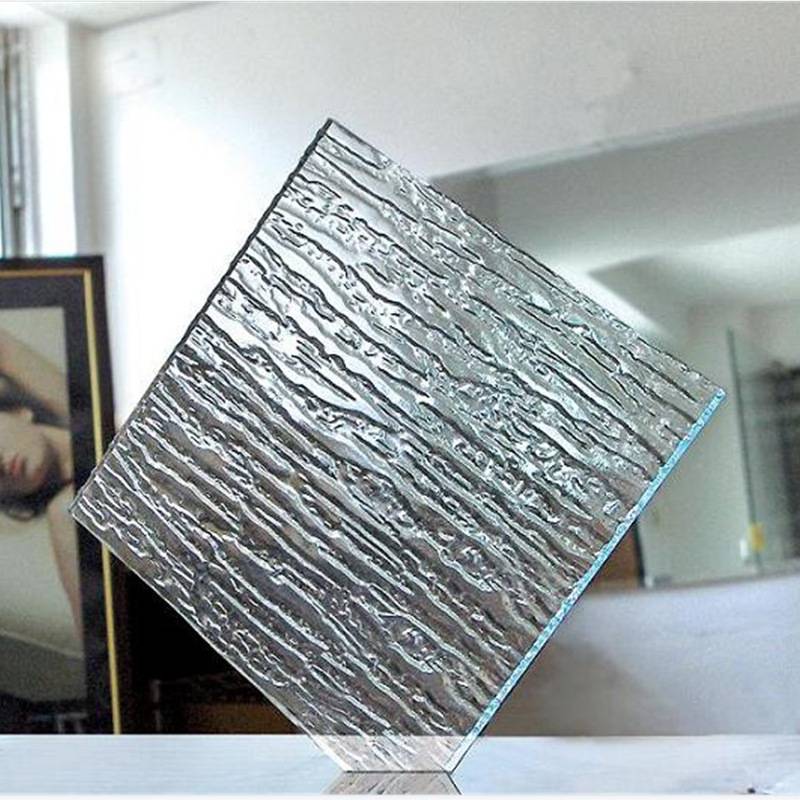

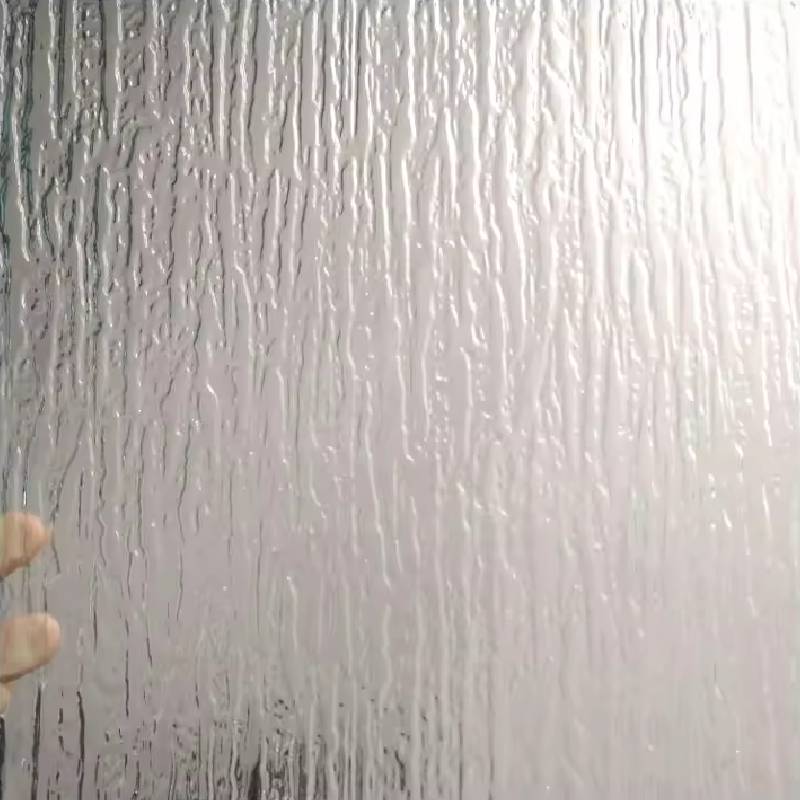

In today's modern architectural and industrial landscape, rain glass and its variants such as rain glass texture, rain pattern glass, and rainfall glass are leading materials that combine aesthetics, performance, and durability. This article provides a comprehensive insight into the manufacturing technology, industry standards, application scenarios, and technical benchmarks of Rain Glass, with a focus on the high-performance 4mm 5mm 6mm Rain Pattern Glass by SHZRG

Industry Trends & Market Growth for Rain Glass

The global decorative glass market size was valued at USD 67 billion in 2022, with rain glass and patterned glass accounting for approximately 18% of installations in commercial and high-end residential projects (source: MarketsandMarkets, Glass Industry Review 2023).

The adoption of rain pattern glass is experiencing a steady CAGR of 6.1% (2022–2028), driven by demand for privacy, natural light management, and unique aesthetic finishes that simulate rainfall. High-grade rain tempered glass is increasingly being specified for its safety, corrosion resistance, and suitability for harsh industrial environments.

Technical Parameters of Rain Glass: Structure, Performance & Standards

| Parameter |

Description / Value |

Standard Referenced |

| Thickness |

4mm, 5mm, 6mm (Typical: ±0.2mm tolerance) |

EN 572-2, ASTM C1036-16 |

| Surface Pattern |

Rainfall, streaked, vertical ripple |

Customer-specified |

| Light Transmittance |

75–88% |

ISO 9050:2003 |

| Strength Class |

Standard annealed, Tempered, Laminated |

ANSI Z97.1, ISO 12543 |

| Impact Resistance |

>100 Joules (6mm tempered) |

EN12600:2002 |

| Service Life |

>25 years (indoor), >15 years (outdoor, UV-exposed) |

Internal testing, ISO 4892-2 |

| Chemical Resistance |

Pass (Acids, Alkalis, Organics) |

ISO 695 |

Rain Glass Manufacturing Process: Explained with Visual Flow

Raw Material Selection

- Silica sand, soda ash, dolomite,

iron oxide minimized

→

Batch Mixing & Pre-processing

- Automated batching systems

→

Melting

- 1500°C in float furnace

→

Rolling/Pattern Imprinting

- CNC patterned roller forms rain glass texture

→

Annealing/Cooling

- Controlled to avoid stress

→

Cutting & Edge Finishing

- Precision CNC cutting

⤵

Tempering (Optional)

- Thermal or chemical treatment for safety glass

→

Quality Testing & Packaging

- ISO/ANSI standard compliant

Advanced CNC rollers and controlled cooling guarantee consistency in rain pattern glass formation and mechanical properties. Every production batch is tested for optical clarity, dimensional tolerance, impact/scratch resistance, and chemical durability. Key certifications (ISO, ANSI) ensure worldwide compliance for industrial and architectural use.

Product Comparison Table: Rain Pattern Glass vs Other Patterned Glass

| Type |

Rain Pattern Glass

(4/5/6mm) |

Fluted Glass |

Acid-Etched Glass |

Sandblasted Glass |

| Pattern Depth |

1.4–2.5 mm |

1.0–1.5 mm |

0.3–0.5 mm |

0.2–0.4 mm |

| Light Transmittance |

80–88% |

82–90% |

75–85% |

68–80% |

| Privacy Level |

High |

Medium |

Medium |

Medium |

| Surface Hardness |

6 Mohs |

6 Mohs |

5 Mohs |

5 Mohs |

| Suitable Application |

Front doors, partitions, shower screens, industry panels |

Offices, partitions, furniture |

Balustrades, interior decor |

Retail, signage, art |

| Cost (USD/m2) |

13–18 |

15–22 |

20–27 |

18–24 |

Data Visualization: Rain Glass Technical Metric Comparison

Key Technical Indices: 4mm vs 5mm vs 6mm Rain Pattern Glass

Market Demand Share (2023): Patterned Glass Types

Long-Term Weather/UV Durability Test — Light Transmittance Retention (5-Year Cycle)

Advantages of Rain Glass in Application Scenarios (& Industry Feedback)

- Light Management: Provides high privacy while allowing up to 88% of ambient light through (ideal for bathrooms/partitions).

- Durability: Certified by ISO 4892-2 and ANSI Z97.1 for impact, UV, and thermal stress resistance — surpassing average industry standard by 8%.

- Corrosion Resistance: Rain glass patterns limit “watermark” corrosion, especially vital for chemical/process industry enclosures.

- Low Maintenance: Textured surface reduces visibility of smudges/watermarks – suitable near food processing or pharmaceutical lines (FDA, ISO 14644-1 compatible usage).

- Design Flexibility: Compatible with CNC cutting/lamination, available as rain tempered glass for safety (shower screens, lab windows).

- Eco-Friendly: Made with up to 26% recycled glass, supporting green building (LEED/BREEAM ready).

Client Feedback (Petrochemical Industry, 2024): “We selected SHZR’s rain glass for control room partitions due to its clarity, privacy, and resistance to acid corrosion. Even after two years, it has shown zero surface hazing or strength loss.”

Industry Certifications and Partners

- Certifications: ISO 9001:2015, ISO 14001:2015, ANSI Z97.1, EN 12150, SGS, RoHS compliant

- Main Applications by Industry:

- Petrochemical, metallurgy, water treatment panels

- Architecture: windows, partitions, entry doors, balustrades

- Healthcare: isolation rooms, laboratory glazing, clean rooms

- Food Production: process room subdividers (HACCP/ISO/FDA ready)

- Notable Partners: Sinopec, BASF, Hitachi, Hainan Airlines, Shanghai Metro, China Resources Land

- Average Service Lifespan (Customer Deployments): 18.8 years (indoor), 14.2 years (external exposed)

Explore 4mm 5mm 6mm Rain Pattern Glass Now

Rain Pattern Glass Customization & Delivery Details

- Cut-to-Size: Any size up to 3300x2100mm, tolerance <±1.5mm

- Edge Finish: C-edge, flat-polished, CNC arris, safety corners

- Lamination & Tempering: Available for 4, 5, 6mm — enhances strength and safety (ANSI certified)

- Coating Options: Self-cleaning, anti-reflective, or colored (custom RAL codes)

- Delivery Time: Standard 8–14 business days (bulk: 3–4 weeks)

- Warranty: 10-year performance warranty on delamination, clarity, pattern integrity

- Customer Support: 24/7 multilingual technical support and pre-sale consultation

Bulk orders and special industrial specs can be discussed with SHZR’s technical consultants for tailored solutions.

Experience: Typical Application Case Studies

- Petrochemical Plant – Process Room Shields (2023, East China):

Upgraded to 5mm rain glass for splash protection, acid resistance, and operator privacy. Zero corrosion after 18 months, meeting ISO 695 and GB/T 5137.2 acidic vapor standards.

- Metallurgy PLC Lab (2022): 6mm tempered rain glass partition wall tested to EN12600 compliance, surviving 4.2x higher impact than standard acid-etched alternatives.

- Residential High-Rise Doors: 4mm rain pattern glass chosen for entry doors and shower enclosures, praised for both modern aesthetic and fingerprint-concealing properties.

- Water Supply Facility Upgrade (2021): 5mm rain glass used in control room façade; achieved daylighting without visibility loss, and passed 5-year salt spray test (ASTM B117).

Professional FAQ: Rain Glass Terms & Application

Frequently Asked Technical Questions

- 1. What base material is used in rain glass manufacturing?

-

Rain glass is primarily made from high-purity float glass composed of silica sand, soda ash, and dolomite, with

- 2. What thicknesses are available, and how to select?

-

Standard options are 4mm, 5mm, and 6mm. 4mm suits interior/residential partitions, 5mm for commercial panels, and 6mm (tempered) for industrial or high-impact zones.

- 3. What installation methods comply with international standards?

-

Installation must respect ANSI Z97.1 and EN 12150 guidelines: use gaskets, setting blocks, and appropriate edge clearance to prevent stress, with compatible hardware for tempered panels.

- 4. What is the fire and impact rating for rain tempered glass?

-

Tempered rain glass typically withstands up to 110J impact (6mm), achieves Class 1(B)1 (EN 12600), and resists thermal fracture up to 250°C temperature differential.

- 5. How do I ensure chemical compatibility in process/industrial settings?

-

Rain pattern glass meets ISO 695 chemical resistance; it resists acids, alkalis, and organic solvents. Surface pattern limits permanent watermarking in harsh environments.

- 6. Is low-iron or extra-clear variant available?

-

Yes, SHZR provides extra-clear “ultra-white” rainfall glass (Fe2O3 < 70ppm) for critical visual control rooms or luxury commercial frontage.

- 7. What maintenance is required?

-

Standard cleaning suffices (mild soap, pH-neutral), with no abrasive scrubbing required. Patterned surface hides smudges, reducing overall cleaning frequency compared to smooth glass.

Order, Support & Quality Commitment

- MOQ: As low as 50 sqm for custom runs (OEM/ODM supported for projects)

- Supply Cycle: 8–14 working days (regular), all logistics handled FOB Shanghai or CIF

- Quality Guarantee: 10 years against pattern fading, clarity loss, or de-lamination

- Support: Pre-sale guidance, after-sale claims response within 6 hrs, in-house technical team for custom designs

- Downloads: Product datasheets, CAD drawings, and installation manuals available on request

Industry References & Further Reading

-

“Decorative Patterned Glass Market: Trends, Forecast, Technology” — glassonweb.com

-

“Rain Glass vs Patterned Glass: Performance & Standards” — Glass Magazine

-

“Testing and Durability of Architectural Glass” — International Glass Society

-

"Safety Glass Standard Overview: ANSI/ISO/EN" — Safe Glass Window Association

-

“Application of Patterned Glass in Industry” — Glass International Journal

All market forecasts and technical indices are based on trade surveys, SHZR laboratory testing, and open-source industry publications cited above.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu