The Advantages of Cutting Toughened Glass A Comprehensive Overview

Toughened glass, also known as tempered glass, has gained immense popularity in various applications due to its strength and safety features. When it comes to cutting toughened glass, the process requires specialized techniques and tools. Understanding the intricacies of this process is essential for both manufacturers and consumers who wish to utilize this versatile material effectively.

Toughened glass is created through a thermal or chemical process that increases its strength compared to regular glass. This process involves heating glass to high temperatures and then rapidly cooling it, which imparts internal stresses that make it more resistant to impact and thermal shock. When broken, toughened glass shatters into small, blunt pieces, reducing the risk of injury—a crucial safety feature in construction and automotive applications.

Cutting toughened glass presents unique challenges due to its increased hardness and resilience. Unlike standard glass, which can be easily cut with a glass cutter, toughened glass requires precision and expertise. The initial step in cutting involves measuring and marking the glass accurately, as any mistakes can lead to the loss of the entire sheet. It is essential to use the correct cutting tools, typically diamond-tipped blades or specialized glass saws, to ensure clean and precise lines.

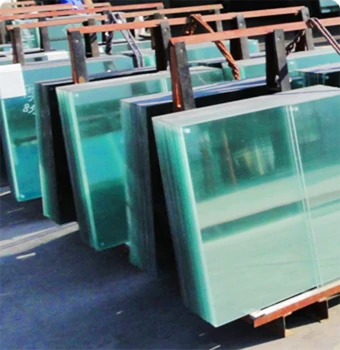

cutting toughened glass

One of the key considerations in cutting toughened glass is ensuring that the glass is not re-tempered or subjected to additional heat after cutting. Doing so can compromise its structural integrity and negate the benefits of toughening. Therefore, it is imperative to conduct the cutting process with care and understanding of the material’s properties.

Moreover, pre-cutting toughened glass into desired shapes and sizes before the tempering process is often recommended. This method not only simplifies the cutting process but also maintains the glass's tempered state, allowing manufacturers to create customized solutions while ensuring safety.

The applications of toughened glass are vast, ranging from shower doors and glass façades to tabletops and glass balustrades. Its durability and aesthetic appeal make it a preferred choice in modern architecture, and its safety features provide peace of mind for consumers. As construction and design trends continue to evolve, the demand for toughened glass is likely to increase, further highlighting the importance of expertise in cutting techniques.

In conclusion, cutting toughened glass is a specialized skill that requires knowledge and precision. By understanding the properties of toughened glass and employing the right techniques, manufacturers and craftsmen can leverage this innovative material to fulfill various design and structural needs while prioritizing safety and efficiency. Whether for commercial or residential applications, toughened glass represents a testament to modern engineering and design.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu