Low Iron Glass Manufacturers Innovation and Sustainability in the Glass Industry

In recent years, the demand for low iron glass has surged, driven by its superior optical clarity and aesthetic appeal. Low iron glass, which contains minimal iron content, is prized for its ability to transmit light with minimal distortion, making it an ideal choice for various applications, including architecture, solar energy, and interior design. As a result, low iron glass manufacturers are at the forefront of innovation, developing new technologies and processes to enhance efficiency and sustainability while meeting the growing market demands.

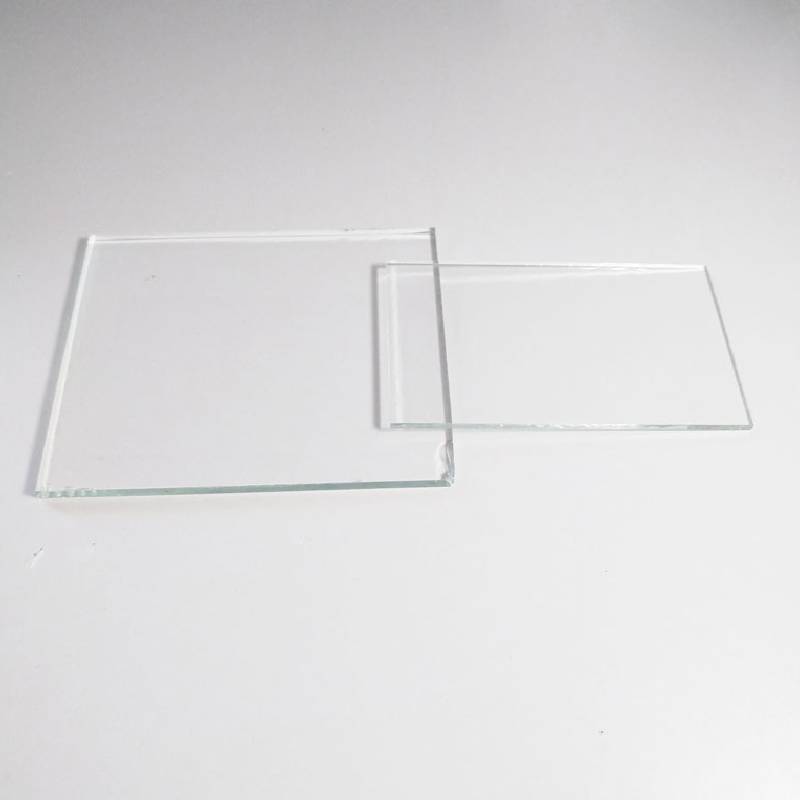

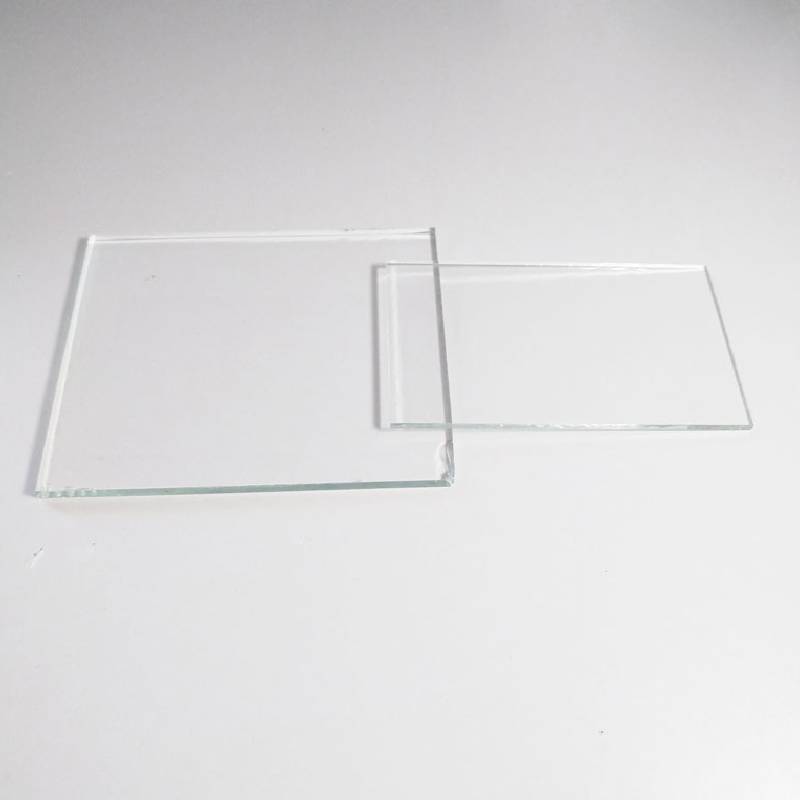

One of the key advantages of low iron glass is its exceptional transparency. Unlike standard glass, which can have a greenish tint due to iron impurities, low iron glass offers a crystal-clear appearance, allowing architects and designers to create visually stunning spaces that maximize natural light. This property makes it particularly popular for use in facades, skylights, and glass railings, where aesthetic appeal and light transmission are critical.

Manufacturers are increasingly turning to advanced technology to produce low iron glass more efficiently. Cutting-edge production methods, such as float glass technology, allow for the precise control of the glass composition, resulting in products that meet stringent quality standards. Automation and smart manufacturing processes enable manufacturers to reduce waste and increase production speed, ensuring that they can respond swiftly to market demands without compromising quality.

low iron glass manufacturers

Sustainability is also a significant focus for modern low iron glass manufacturers. As the construction and design industries strive for greener solutions, the demand for eco-friendly materials is on the rise. Many manufacturers are adopting practices that minimize their environmental footprint, such as recycling cullet (crushed glass from production waste) to create new glass. This not only reduces the need for raw materials but also lowers energy consumption in the melting process, aligning with global sustainability goals.

Additionally, low iron glass plays a crucial role in energy-efficient buildings. Its high light transmission supports passive solar heating, reducing dependency on artificial lighting and lowering energy costs. As cities across the globe invest in sustainable infrastructure, low iron glass becomes an integral component in achieving energy-efficient designs that benefit both the environment and occupants.

The versatility of low iron glass allows manufacturers to cater to diverse industries, from high-end residential projects to large-scale commercial developments. Specialists in this market are continually exploring new applications, such as in solar panels and energy-efficient windows, further broadening the scope of low iron glass use.

In conclusion, low iron glass manufacturers are embracing innovation and sustainability to meet the increasing demand for this versatile material. Through advanced production techniques, eco-friendly practices, and a commitment to quality, these manufacturers are not only enhancing the aesthetic and functional aspects of architecture and design but also contributing to a more sustainable future. As the market expands, the role of low iron glass will undoubtedly continue to grow, shaping the landscape of modern construction and design in the process.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu