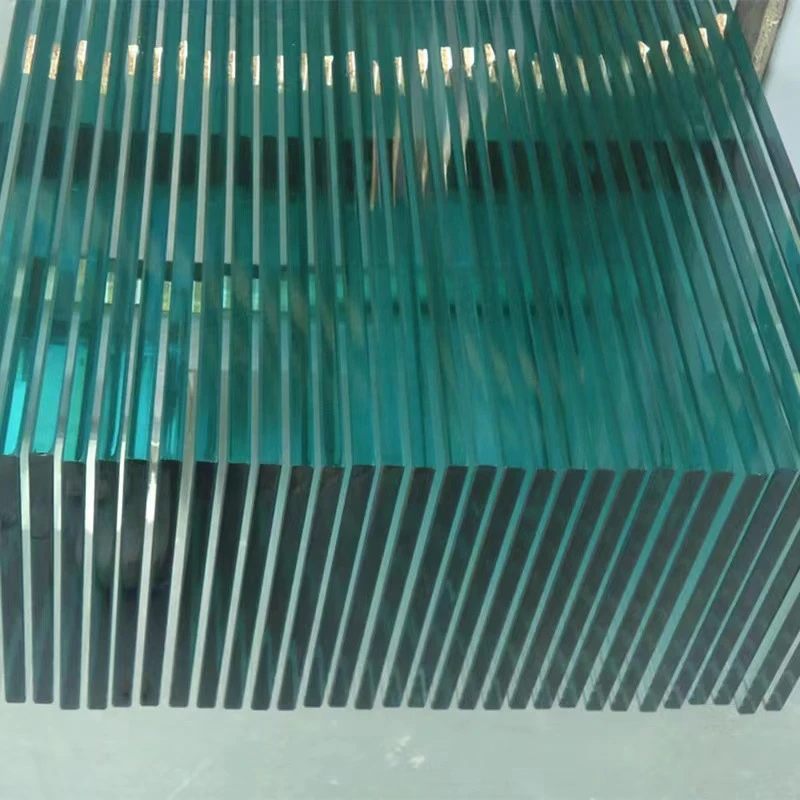

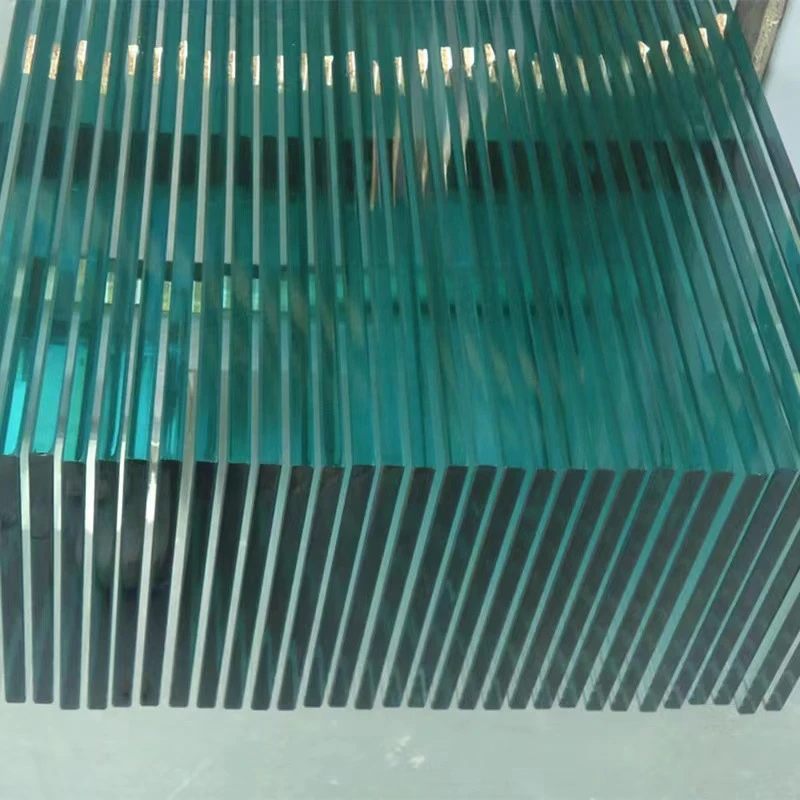

Float glass, a staple in modern construction and design, revolutionized the glass production industry with its uniformity and quality. Unlike traditional glassmaking techniques that often resulted in imperfection-laden surfaces, float glass emerged as a remarkable innovation, ensuring consistently flat and clear glass sheets. This method, pioneered in the mid-20th century, involves pouring molten glass onto a bed of molten tin. The glass naturally spreads out to form a perfectly flat surface due to its high temperature and gravity’s equalizing influence. This breakthrough allowed manufacturers to produce glass with an unprecedented level of smoothness and optical clarity, propelling it to primacy in both architectural and decorative applications.

Float glass's significance extends beyond its manufacturing process, impacting structural and aesthetic elements in various industries. In architecture, it offers designers the liberty to create expansive windows and facades, promoting natural light infiltration and energy efficiency within buildings. The uninterrupted surfaces of float glass enhance views and augment the sense of space inside structures. From grand skyscrapers to residential buildings, float glass meets both functional and aesthetic demands, contributing significantly to sustainable building practices.

In interior design,

float glass's adaptability is equally transformative. Designers capitalize on its versatility to create furniture, partitions, and decorative elements that align with modern minimalistic and contemporary styles. The clear and non-distorted quality of float glass is particularly valued in developing mirrors, tabletops, and shelving, ensuring they seamlessly integrate into varied environments while retaining a luxurious feel.

float glass meaning

The technological advances in float glass production further underline its role as a product capable of embracing specialty applications. It sets the foundation for producing laminated and tempered glass variants, enhancing safety and durability—two critical aspects in construction safety standards. When laminated, it withstands impacts without shattering completely, thus preventing injuries and reinforcing its place in automotive windows and skylights. When tempered, it breaks into small, harmless pieces, offering an added layer of protection crucial for shower doors and facades subjected to high wind loads.

Automation and precision in the float glass manufacturing process also underscore the industry's commitment to efficiency and ecological responsibility. Modern facilities implement cutting-edge technologies such as computer-controlled processes to ensure minimal waste and energy consumption, aligning with global trends toward greener industrial practices. These advances not only uphold the environmental sustainability of float glass production but also reflect the industry's adaptability to emerging environmental standards and consumer expectations.

For industry professionals and consumers alike, understanding float glass's inherent qualities and potential applications fosters informed decision-making when selecting materials for construction or design purposes. Its unmatched flatness, clarity, and subsequent adaptability position float glass as a leading choice in various scenarios. By continually evolving and meeting the challenges of modern construction and environmental disciplines, float glass remains a testament to natural resource utilization and innovative thought in design and functionality.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu