Float flat glass, a crucial component in the architectural and automotive industries, stands out for its remarkable versatility and indispensable qualities. As an enduring staple in glass manufacturing, the process of creating float flat glass involves a meticulously controlled environment that yields an unparalleled level of precision and quality. This article aims to delve into the unique characteristics, expert production methods, and multifaceted applications of float flat glass, all of which underscore its significance in the modern world.

Delving into the production expertise, float flat glass is produced using the float process—a revolutionary method developed in the 1950s that transformed the glass manufacturing landscape. This process begins with raw materials such as silica sand, soda ash, and limestone being melted in a furnace at temperatures exceeding 1700°C. The molten glass is then carefully poured onto a bath of molten tin. Due to gravity and surface tension, the glass spreads evenly over the tin surface, resulting in perfectly flat sheets. These sheets pass through a controlled cooling atmosphere, known as the annealing lehr, where they gradually cool down, relieving any internal stresses and achieving optimal strength and durability.

What sets float flat glass apart is its impeccable smoothness and uniform thickness, which are consistently maintained due to the controlled production process. This precision makes it the preferred choice for a wide range of applications, from high-rise building windows to vehicle windshields and even solar panels. The ability to produce glass that is both optically clear and mechanically strong contributes to its extensive use in areas where both safety and aesthetics are paramount.

In terms of authoritative industry experience, manufacturers maintain stringent quality control measures to ensure only top-standard glass reaches the market. Studies have shown that the demand for energy-efficient building materials is on the rise, and float flat glass plays a pivotal role in this transition. Experts in architectural design emphasize the importance of selecting materials that contribute to sustainable building practices. Float flat glass, often enhanced with coatings that improve thermal insulation and solar control, aligns perfectly with these eco-conscious strategies.

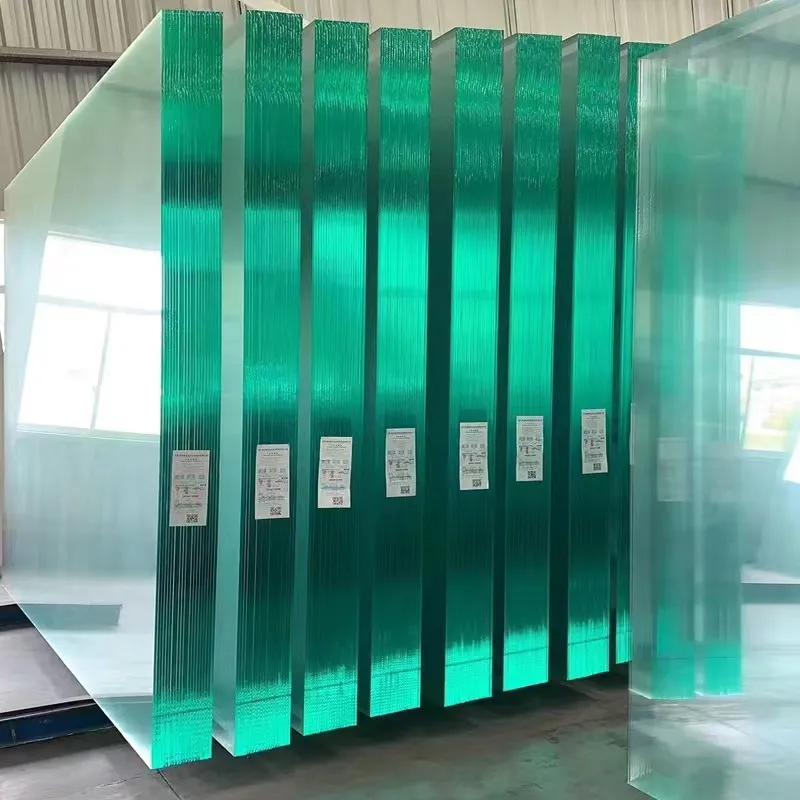

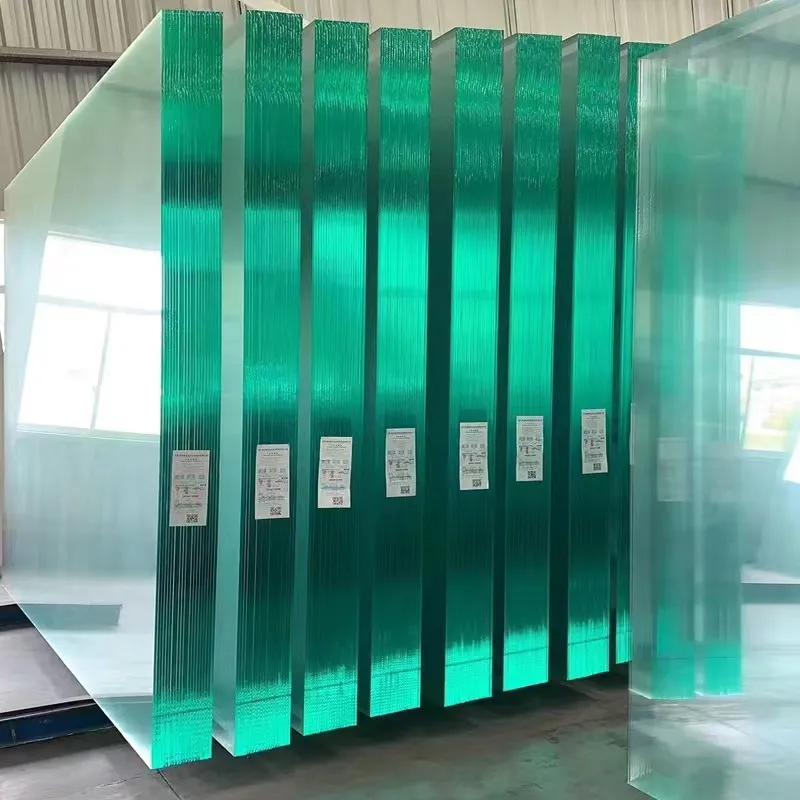

float flat glass

From an application expertise perspective, float flat glass is not confined to traditional window or glass door usage.

It finds itself at the heart of innovative designs and technological advancements. For instance, in the automotive sector, enhanced float glass contributes to vehicles’ structural integrity while allowing for superior acoustics and climate control within the cabin. Its adaptability extends to smart glass technologies where its surface can be embedded with sensors or transformed from clear to opaque on demand, revolutionizing user interactivity and privacy.

Trustworthiness in using float flat glass is evident through its widespread regulatory compliance and industry accreditations. Certified under international safety and quality standards, such as ISO and ASTM, the reliability of float flat glass ensures that its application in safety-critical structures can be trusted by architects, builders, and end-users alike.

In conclusion, the pervasive utility and superior properties of float flat glass make it an undeniable asset across numerous industries. Its production process exemplifies innovation and expertise, while ongoing advancements continue to expand its potential applications. As a product deeply embedded with trustworthiness, authoritative quality, and expert craftsmanship, float flat glass not only meets the demands of the present but also anticipates the needs of the future, affirming its position as an invaluable component in the modern material landscape. By comprehensively understanding its attributes and capabilities, stakeholders and professionals can make informed decisions that leverage the full potential of float flat glass to enhance their projects and products.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu